Comprehensive Guide to Material Selection for Pressure Vessel Design

Table of Contents

ToggleIntroduction to Best Materials for Pressure Vessels

Pressure vessels are more than just components; they’re the lifelines in industries like Oil and Gas, Power Generation, and Biogas. These vessels keep gases or beverages at a pressure considerably specific from the ambient pressure, making their integrity vital. At Red River, we don’t simply manufacture pressure vessels; we create robust answers that play a pivotal role in the success of numerous industries. Our crew thrives on challenges, continuously gaining knowledge of and innovating to make an enormous impact on society.

The Importance of Proper Material Selection

Choosing the right fabric for pressure vessel creation isn’t always just a technical choice; it is a dedication to protection and performance. The right fabric choice impacts the vessel’s overall performance, durability, and compliance with industry standards. Our approach at Red River is to combine our deep know-how of fabric properties with your unique challenge necessities. This guarantees that each vessel we manufacture no longer most effectively meets but exceeds the rigorous demands of its supposed software.

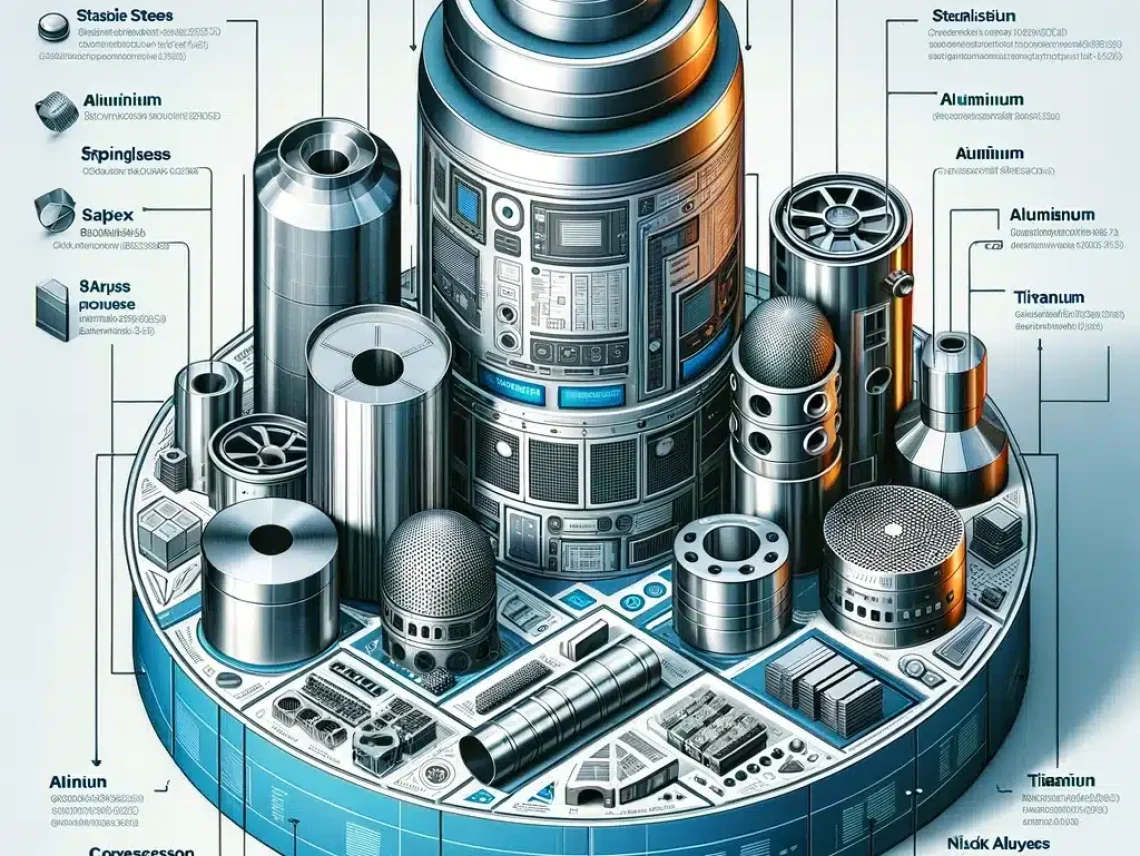

Overview of Common Materials Used in Pressure Vessels

In our pursuit of excellence, we utilize many materials, every selected for its particular properties and suitability for specific applications. Carbon metal, regarded for its durability and power, is a popular desire for many well-known packages. Stainless metal, with its first-rate corrosion resistance, is right for harsher environments. For greater specialized needs, we flip to advanced alloys and composite materials, supplying improved overall performance under extreme situations.

Criteria for Selecting Best Materials for Pressure Vessels

Strength and Durability Considerations

The electricity and sturdiness of substances are paramount. We pick materials that can face up to excessive pressures and withstand put on over the years, making sure of long-term reliability.

Corrosion Resistance in Material Selection

Corrosion resistance is vital for maintaining the integrity of the vessel. We pick out materials that may endure harsh environments and chemical exposures.

Temperature and Pressure Tolerances

Our substances need to withstand severe temperatures and pressures, ensuring consistent overall performance below various operational situations.

Cost-Effectiveness and Material Availability

We balance performance with cost-effectiveness and availability, ensuring our answers are superb and available.

Types of Materials Used in Pressure Vessel Design

Carbon Steel: A Popular Choice

Carbon steel is preferred for its power and versatility, ideal for more than a few applications.

Stainless Steel for Corrosion Resistance

Stainless metal offers remarkable corrosion resistance, making it appropriate for harsh environments.

Alloy Materials for Specialized Applications

Alloys are selected for specialized programs, providing more advantageous properties like heat resistance.

Composite Materials: The Future of Pressure Vessels

Composites represent the future, offering excessive electricity-to-weight ratios and corrosion resistance.

Advanced Materials in Pressure Vessel Technology

Innovations in Material Engineering

Our group stays abreast of the modern-day improvements in cloth engineering.

High-Performance Alloys

High-overall performance alloys are used for their excellent houses below extreme situations.

The Role of Nanomaterials in Pressure Vessel Design

Nanomaterials are explored for his or her particular benefits in improving vessel performance.

Design Considerations for Different Pressure Vessels

Materials for High-Pressure Applications

We choose substances in particular designed to handle high pressures.

Low-Pressure Vessel Material Choices

For low-pressure packages, we select materials that offer the right stability for residences.

Custom Material Solutions for Unique Needs

Custom solutions are developed for unique venture requirements.

Industry Standards and Compliance in Material Selection

ASME Standards for Pressure Vessels

We adhere to ASME requirements, ensuring protection and great.

International Material Standards and Regulations

Our materials comply with international standards and regulations.

Ensuring Safety and Efficiency

Safety and performance are in the middle of our material selection manner.

Sustainable Material Options for Pressure Vessels

Eco-Friendly Material Choices

We explore substances that aren’t handiest durable and green but also have a decreased environmental footprint. This includes recycled substances and those with sustainable manufacturing approaches.

Lifecycle Analysis of Vessel Materials

Our group conducts thorough lifecycle analyses to understand the environmental effects of substances from manufacturing to disposal, ensuring a sustainable method for the duration of the vessel’s existence.

Balancing Sustainability and Performance

We try to discover the perfect stability between sustainability and performance, ensuring our pressure vessels are environmentally friendly and functionally advanced.

Case Studies: Successful Material Selection in Practice

Real-World Applications and Outcomes

We show off various initiatives wherein our fabric selections have led to hit results, demonstrating our expertise and adaptability.

Lessons Learned from Industry Examples

Each task brings new studying, supporting us refine our material selection technique for destiny endeavors.

Innovations in Material Usage

We highlight progressive material makes use of that has revolutionized pressure vessel design and capability.

Future Trends in Pressure Vessel Material Selection

Emerging Materials and Technologies

We’re constantly exploring emerging substances and technology that could redefine pressure vessel production.

Predictions for Future Material Use

Our team keeps an eye fixed on enterprise trends, predicting future cloth uses that align with evolving wishes.

Adapting to Changing Industry Needs

We’re agile and ready to evolve our fabric choice to meet converting industry demands and advancements.

Expert Consultation and Services by Red River LLC

Custom Material Selection Assistance

We offer customized assistance in choosing the proper substances for your specific pressure vessel needs.

Engineering and Design Support

Our crew gives comprehensive engineering and layout assistance, making sure your assignment is fulfilled from start to complete.

Ongoing Maintenance and Material Evaluation

We’re now not pretty much building; we are about maintaining and evaluating, making sure your pressure vessels keep fulfilling the best standards over time.

Need a reliable partner?

FAQs - Pressure Vessel Material Selection

What factors should I consider when selecting materials for a pressure vessel?

When choosing substances for a pressure vessel, numerous important factors come into play. These consist of energy, sturdiness, corrosion resistance, temperature and pressure tolerances, price effectiveness, and cloth availability. Each of these factors needs to align together with your precise venture necessities to ensure superior overall performance and safety.

What are the common materials used in pressure vessel construction?

Pressure vessels may be created from numerous materials depending on the utility. Common selections include carbon metal for its electricity, chrome steel for corrosion resistance, and alloy materials for specialized needs. Composite materials are also gaining traction for her lightweight and corrosion-resistant houses.

How do I balance sustainability with material performance in pressure vessel design?

Achieving sustainability in pressure vessel substances entails choosing eco-friendly alternatives, thinking about the lifecycle evaluation of materials, and finding the right balance between sustainability and performance. Materials with decreased environmental footprints, like recycled or sustainably produced options, can lessen the overall impact.

What are the future trends in pressure vessel material selection?

Future developments in pressure vessel fabric selection are expected to consciousness on rising materials and technologies that provide progressed overall performance and sustainability. This includes nanomaterials, superior alloys, and modern composite substances. Adaptation to changing enterprise wishes and regulatory requirements may even play a tremendous role.

How can Red River LLC assist in selecting the right materials for my pressure vessel project?

Red River LLC provides custom cloth choice help based on your project’s unique wishes. We offer engineering and design guides, making sure that the materials align with your requirements. Our dedication to quality and compliance, together with massive enjoyment, ensures that you get hold of pinnacle-notch answers tailor-made for your specific wishes.

Table of Contents

ToggleRelated Blog Post

- What is the theory of air vessel?

- Who invented pressure vessels?

- What is the pressure theory in physics?

- What is the thick pressure vessel theory?

- What is the ideal pressure vessel shape?

- How does ASME define a pressure vessel?

- What is one criterion for design of a safe pressure vessel?

- What is the minimum design pressure of a pressure vessel?

- Which theory of failure is used while designing a pressure vessel Why?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.