Electron beam welding (EBW) delivers deep penetration, minimal distortion, and clean, high-integrity welds for high-strength steels. It outperforms traditional methods in precision, metallurgical integrity, and efficiency ideal for critical applications like pressure vessels, aerospace, and defense.

What is Electron Beam Welding?

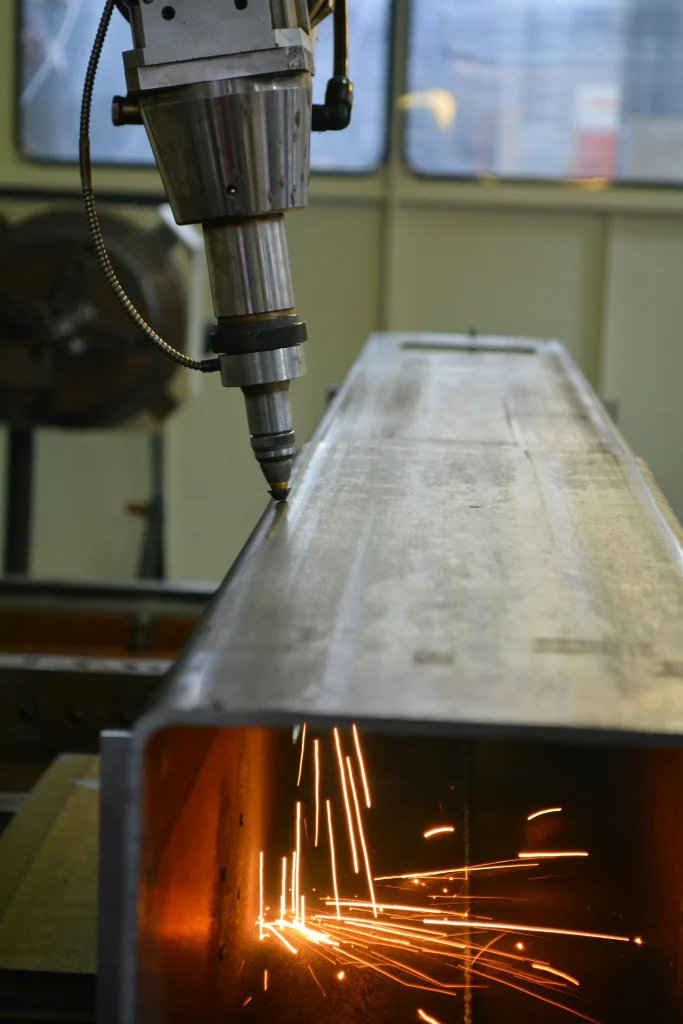

Electron beam welding (EBW) is a precision fusion welding technique that joins materials using a focused beam of high-velocity electrons. As these electrons strike the workpiece, they generate intense localized heat, instantly melting the metal to form a deep, narrow fusion zone. This allows single-pass welding of thick sections while minimizing the heat-affected zone (HAZ) and preserving mechanical properties an important factor in pressure vessel fabrication.

Unlike other fusion processes used in welding as a type of fabrication, electron beam welding is performed in a vacuum environment. This eliminates atmospheric contamination and ensures clean, oxide-free joints that align with rigorous quality assurance requirements.

Advantages for Pressure Vessel Applications

When working with high-strength steels, electron beam welding offers several distinct advantages over traditional arc welding methods commonly found in conventional fabrication processes. The penetration-to-width ratio can exceed 25:1, enabling full joint fusion in materials several inches thick. This precision is critical for components governed by ASME-certified pressure vessel standards.

Because EBW concentrates heat in a very small area, it minimizes distortion and residual stress. This reduces the need for post-weld machining or straightening an efficiency gain especially valuable in modular skid and large-scale industrial assemblies.

Electron beam welding also simplifies joining dissimilar thicknesses, a common challenge in custom pressure vessel and structural steel applications.

Penetration, Precision & Metallurgical Benefits

The focused energy of the electron beam combined with a vacuum environment creates several metallurgical advantages. Welds are free from porosity, oxidation, and hydrogen embrittlement key risks discussed in pressure vessel safety and compliance considerations. Rapid thermal cycling limits grain growth, preserving steel’s mechanical performance.

The narrow HAZ reduces property degradation compared to arc welding, and weld joints can achieve up to 100% of the base material’s strength. For high-strength steels containing reactive alloying elements, EBW supports long-term durability required in pressure vessel inspection and lifecycle management.

Use Cases in Aerospace, Defense & Energy

Electron beam welding is mission-critical in industries that demand uncompromising weld integrity.

In aerospace, EBW is used for landing gear, engine mounts, and structural frames where weight savings and strength are paramount concepts also explored in advanced metal fabrication strategies. Automotive manufacturers apply EBW to transmission gears and driveshafts that require precise welds without excess filler material.

Defense applications include armored systems and vehicle structures, where weld integrity directly affects safety and performance. In the energy sector, EBW is ideal for turbines, generators, and industrial pressure vessels where failure is not an option.

Key Process Parameters & Considerations

Implementing electron beam welding requires careful control of accelerating voltage, beam current, and focus depth. These parameters determine penetration depth and weld width, much like process optimization discussed in precision metal fabrication.

Joint preparation is critical machined surfaces and tight fit-up tolerances are essential. Vacuum chamber size may limit weldable part dimensions unless specialized equipment is used, particularly for large prefabricated assemblies.

While preheating is often unnecessary, some steel grades require post-weld heat treatment to meet code requirements outlined in ASME certification guidelines.

Why Electron Beam Welding Is the Smart Choice

Electron beam welding is a proven solution for joining high-strength steels in demanding environments. It enables deep penetration, precise control, and minimal thermal distortion preserving the material’s mechanical integrity and metallurgical performance.

By adopting electron beam welding, manufacturers can exceed industry code requirements and deliver structurally sound, long-lasting components that meet the highest performance standards for critical applications.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. What types of high-strength steels are most suitable for electron beam welding?

Most high-strength steels respond well to electron beam welding, including HSLA (High-Strength Low-Alloy) steels, maraging steels, precipitation-hardening steels, and ultra-high-strength steels like 4340 and 300M. The process is particularly valuable for steels that are sensitive to heat input or prone to distortion.

2.How does the vacuum environment affect weld quality in high-strength steels?

The vacuum environment prevents oxidation and contamination during welding, which is particularly important for high-strength steels containing reactive alloying elements. This results in cleaner welds with superior mechanical properties and reduced risk of hydrogen embrittlement or other contamination-related defects.

3. What are the thickness limitations for electron beam welding of high-strength steels?

Modern electron beam welding systems can penetrate up to 200mm of steel in a single pass, though practical applications typically involve thicknesses between 0.5mm to 50mm. The exact limitation depends on the specific steel grade, the power of the electron beam system, and the joint design.

4. How does electron beam welding affect the heat-affected zone in high-strength steels?

Electron beam welding produces an extremely narrow heat-affected zone (HAZ) due to its concentrated energy input and rapid cooling rates. This minimizes microstructural changes and property degradation in high-strength steels, helping maintain their designed mechanical properties throughout the welded component.

5. What are the key process parameters to control when electron beam welding high-strength steels?

Critical parameters include accelerating voltage, beam current, focus settings, travel speed, vacuum level, and beam oscillation patterns. These must be carefully optimized for each specific high-strength steel grade to achieve the ideal combination of penetration, fusion zone geometry, and microstructural properties.

6. Is pre-heating or post-weld heat treatment required for electron beam welding of high-strength steels?

Unlike many conventional welding processes, electron beam welding often eliminates the need for pre-heating due to its localized heat input. Post-weld heat treatment requirements vary by steel grade some applications may benefit from stress relief or tempering treatments, while others may require no post-processing.

Key Takeaways

- Electron beam welding delivers unmatched precision for critical high-strength steel applications where material properties must be preserved

- The process provides exceptional depth-to-width ratios with minimal heat input, allowing single-pass welding of thick sections

- Applications span aerospace, automotive, defense, and pressure vessel industries where joint performance is mission-critical

- Proper parameter selection and joint preparation are essential for achieving optimal weld quality in high-strength steels

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author