Exploring the Nuts and Bolts of Material Handling

Table of Contents

ToggleIntroduction to the difference between a pallet and a skid

In the bustling world of warehousing and logistics, clear terminology ensures smooth operations and prevents miscommunication. Among the many terms used, pallets and skids often cause confusion. At first glance, these platforms might seem interchangeable. Both are used to transport and store goods and are commonly found in warehouses, on trucks, and at docks.

However, a closer look reveals distinct differences between the two. Each has its own unique history, design, and purpose. Understanding these differences helps businesses and individuals make informed decisions about their warehousing and transportation needs. This article highlights the key distinctions between pallets and skids, offering insights to clarify their usage.

Historical Context

The evolution of global trade and warehousing has tightly intertwined with the story of pallets and skids. These tools have roots stretching back centuries, but their importance became most evident in modern times.

Pallets:

Modern pallets emerged during World War II when the military needed efficient ways to store and transport goods. This demand led to the development and widespread adoption of pallets. Around the same time, the introduction of forklift trucks revolutionized warehousing by enabling easier movement of these platforms. Over the years, pallets evolved with new materials and designs, catering to the diverse needs of various industries.

Skids:

In contrast, skids have a much older history. Long before pallets were invented, people used skids—simple wooden platforms or sleds—to move goods. Without bottom deck boards, skids were often dragged or pushed, making them suitable for non-mechanized equipment. Their straightforward design and durability made them a staple in warehouses and docks for centuries.

As modern transportation methods advanced, the distinction between pallets and skids grew clearer. Pallets became the go-to solution for flexibility and compatibility with emerging technologies, while skids found niche applications in specific industries.

Definition and Key Features

Pallet

Definition: A pallet is a flat transport structure that supports goods in a stable manner, allowing them to be lifted by forklifts, pallet jacks, or other lifting devices. Pallets are designed to be easily moved, stored, and stacked, facilitating the efficient transportation and storage of goods.

Common Materials Used: Pallets can be made from a variety of materials, including:

- Wood: The most common material, known for its durability and cost-effectiveness.

- Plastic: Lightweight and often used for its resistance to moisture, chemicals, and pests.

- Metal: Typically used in specialized industries due to its strength and longevity.

Typical Design Features:

- Bottom Deck Boards: These provide additional support and stability to the goods being transported.

- Multiple Entry Points: Designed for forklift tines, allowing for lifting from various angles.

Skid

Definition: A skid is one of the earliest forms of a pallet. It’s a single-deck loading platform that lacks the bottom deck boards found in pallets. Skids are primarily used to place heavy items on them, either for storage or for dragging/moving.

Historical Significance: As previously mentioned, skids have been in use for centuries, serving as the primary means of storing and moving goods before the advent of the modern pallet.

Design Features:

- Lack of Bottom Deck Boards: This is the most distinguishing feature of skids, setting them apart from pallets.

- Single Entry Point: Typically, skids are designed to be lifted or moved from one side, unlike pallets which can often be accessed from multiple sides.

Main Differences Between Pallets and Skids

Structural Differences:

- Pallets: Feature both top and bottom deck boards. This dual-deck design provides added stability and allows for an even distribution of weight. It also facilitates easier handling by forklifts from multiple directions.

- Skids: Have only a top deck without the bottom boards. This single-deck design is more rudimentary and is reminiscent of their historical use as simple sleds or platforms.

Load-Bearing Capacities:

- Pallets: Generally designed to bear heavier loads due to their robust structure. The presence of bottom deck boards provides additional support, making them suitable for a wide range of goods.

- Skids: While they can support substantial weight, their load-bearing capacity is often less than that of pallets, especially when considering dynamic loads or movement.

Usage Scenarios:

- Pallets: Preferred in modern warehousing, retail, and transportation sectors due to their versatility and compatibility with various lifting equipment.

- Skids: Often found in industries or scenarios where goods remain stationary for extended periods or where dragging is more common than lifting.

Cost Implications:

- Pallets: Due to their complex design and the materials used, pallets can be more expensive than skids. However, their durability and versatility often justify the cost.

- Skids: Simpler in design and often cheaper to produce. However, their limited functionality might lead to additional costs in specific scenarios, such as when specialized handling is required.

Advantages and Disadvantages

Pallet

Pros:

- Versatility: Pallets are adaptable to a wide range of storage and transportation needs, making them suitable for various industries.

- Safety: The dual-deck design provides stability, reducing the risk of goods toppling over during transportation or storage.

- Ease of Handling: Multiple entry points for forklift tines ensure that pallets can be easily lifted, moved, and stacked from different angles.

Cons:

- Cost: Pallets, especially those made of durable materials or specialized designs, can be more expensive than skids.

- Potential for Damage: If not handled correctly, the goods on a pallet or the pallet itself can get damaged. This is especially true for wooden pallets that can splinter or break under extreme stress.

- Maintenance: Pallets may require regular inspections and repairs to ensure they remain in good condition, adding to their overall cost.

Skid

Pros:

- Simplicity: Skids have a straightforward design, making them easy to produce and use.

- Durability: Due to their basic structure, skids often have fewer components that can break or wear out, leading to longer lifespans in certain scenarios.

- Historical Significance: For businesses or industries that value tradition, skids offer a nod to historical warehousing and transportation methods.

Cons:

- Limited Handling Options: Skids are typically designed to be moved from one side, which can pose challenges in tight spaces or when using certain equipment.

- Potential Instability: Without bottom deck boards, skids might not offer the same level of stability as pallets, especially when loaded unevenly.

- Less Versatile: Skids may not be suitable for all industries or storage scenarios due to their design limitations.

Modern Innovations and Trends

Hybrid Pallet-Skid Systems:

Combining the best of both worlds, hybrid systems are emerging that offer the simplicity of skids with the versatility of pallets. These hybrids are designed to be adaptable, catering to a broader range of storage and transportation needs.

Environmental Considerations:

- Recyclable Materials: With growing environmental concerns, there’s a shift towards using recyclable materials in pallet and skid production. Plastic pallets, for instance, can be melted down and reshaped multiple times.

- Sustainable Sourcing: Wooden pallets and skids are increasingly sourced from sustainable forests, ensuring minimal environmental impact and promoting responsible forestry.

Technological Advancements:

- Smart Pallets: Incorporating IoT (Internet of Things) technology, smart pallets can track and relay information about the goods they carry, their location, and even conditions like temperature or humidity.

- RFID Tags: Both pallets and skids are now often equipped with RFID (Radio Frequency Identification) tags, facilitating easier tracking and inventory management.

Design Innovations:

- Modular Designs: Some modern pallets are designed to be modular, allowing for customization based on specific goods or storage conditions.

- Enhanced Durability: New materials and construction techniques are being employed to make pallets and skids more durable, reducing the need for frequent replacements.

Safety Enhancements:

- Anti-slip Surfaces: To prevent goods from sliding off, many pallets now feature anti-slip surfaces or coatings.

- Ergonomic Designs: Considering the well-being of workers, some pallets and skids are designed with ergonomic considerations, ensuring easier and safer handling.

Need a reliable partner?

FAQ: Understanding the Difference Between Pallets and Skids

What are the key differences between a pallet and a skid?

A pallet and a skid are both platforms used for transporting and storing goods, but they have distinct structural differences. A pallet is a flat structure with both a top and bottom deck, providing stability and facilitating the lifting by forklifts from all sides. In contrast, a skid has a single-deck design, lacking a bottom deck, which makes it a simpler and older form of a pallet. This single-deck structure means skids are often used as a base for heavy machinery, as they are easier to drag or pull.

How does the choice between a pallet and a skid impact the handling of goods?

The choice between using a pallet or a skid significantly affects how goods are handled and transported. Pallets, with their double-deck structure, offer more stability and are better suited for stacking, making them ideal for storage and transport in warehouses. Skids, due to their single-deck design, are less stable but easier to move and drag, making them suitable for heavier items that are not frequently moved.

Are pallets or skids more cost-effective for businesses?

The cost-effectiveness of pallets versus skids depends on the specific needs of a business. Skids are generally less expensive due to their simpler design and are more durable when used as a base for heavy machinery. Pallets, although more expensive, offer greater efficiency in stacking and storing, potentially reducing storage and transportation costs. Businesses must evaluate their specific needs, including the types of goods they handle and their storage capabilities, to determine the most cost-effective option.

Can pallets and skids be customized for specific industrial needs?

Yes, both pallets and skids can be customized to meet specific industrial requirements. This customization can include size adjustments, choice of material (wood, plastic, metal), and design modifications to accommodate different weights and dimensions of products. Customization ensures that businesses can maximize efficiency in storage and transportation while ensuring the safety of their goods.

What are the environmental considerations when choosing between pallets and skids?

Environmental considerations are crucial when choosing between pallets and skids. Wooden pallets and skids are often made from renewable resources and are recyclable, but they can have a larger environmental footprint due to their weight and the need for more frequent replacement. Plastic pallets, while more durable and often made from recycled materials, require more energy to produce. Businesses should consider the lifecycle and environmental impact of these platforms, including their manufacturing process, durability, and recyclability, to make a responsible choice.

Solutions

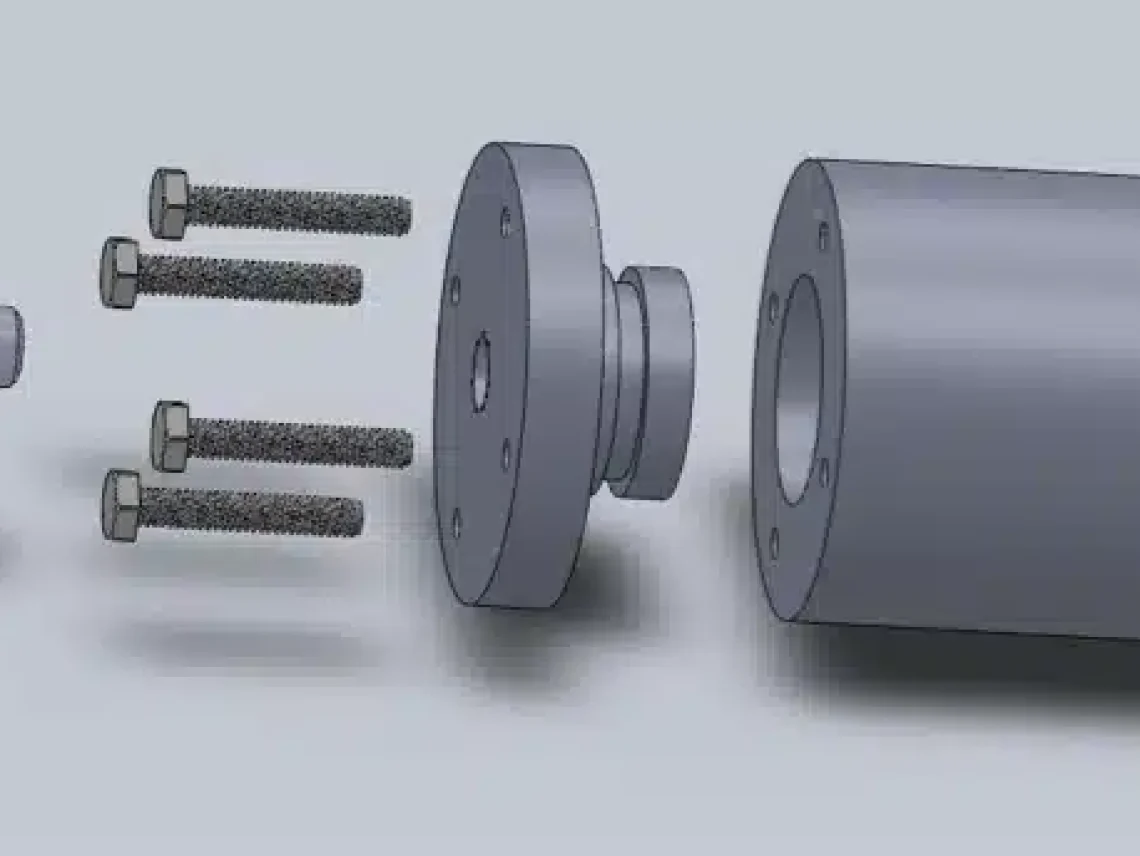

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.