Metal Fabrication vs Manufacturing

Understanding Metal Fabrication vs Manufacturing

When it comes to industrial production, metal fabrication vs manufacturing highlights two distinct but often confused processes. While both contribute to turning raw materials into functional products, they differ in methods, goals, and applications. Understanding metal fabrication vs manufacturing is essential for professionals in construction, engineering, and production who aim to optimize efficiency, quality, and resource use.

What Is Metal Fabrication?

Metal fabrication involves creating custom metal structures or components by cutting, bending, welding, and assembling raw metal materials. It’s a precision-driven process, often tailored for specific projects in industries like construction, aerospace, energy, and automotive.

Common Metal Fabrication Processes

- Cutting: Using lasers, water jets, or plasma torches

- Bending: Forming shapes via press brakes

- Welding: Joining metal with heat and filler

- Machining: CNC milling, drilling, or turning

- Assembling: Building final structures from components

What Is Manufacturing?

Manufacturing refers to the mass production of goods using raw materials and machinery. In contrast to metal fabrication, manufacturing typically involves automation and repetition, producing identical items in large volumes—often with less customization.

Examples of Manufacturing Processes

- Injection molding

- Stamping and forming

- Casting and forging

- Assembly line production

- 3D printing in plastics or metals

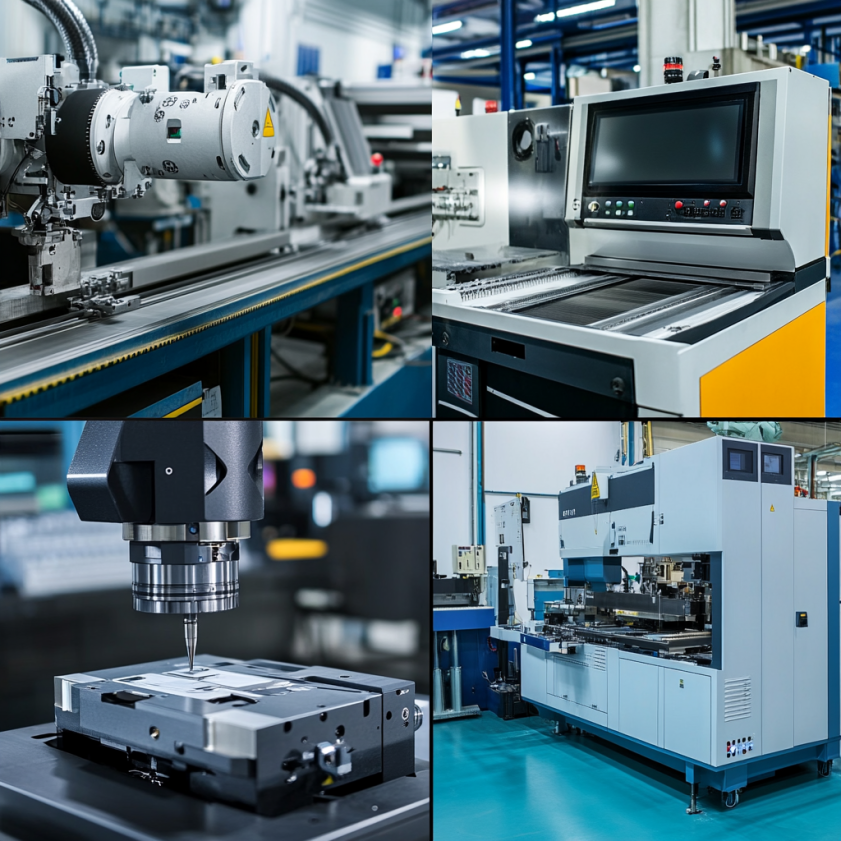

Tools Used in Fabrication vs Manufacturing

Fabrication shops use:

- CNC plasma cutters

- MIG and TIG welding machines

- Sheet metal rollers

- Press brakes

Manufacturing plants use:

- Injection molding machines

- Hydraulic presses

- Automated assembly lines

- Robotic arms and conveyors

When to Use Fabrication vs Manufacturing

- Metal Fabrication: Best for custom, low-quantity, high-complexity parts

- Manufacturing: Ideal for high-volume, repeatable products at scale

Key Differences Summarized

Here’s how metal fabrication vs manufacturing compare:

- Output Volume

- Metal fabrication: Low to medium

- Manufacturing: Medium to high

- Customization

- Metal fabrication: Highly customizable

- Manufacturing: Limited customization

- Flexibility

- Metal fabrication: Very flexible for one-off or complex jobs

- Manufacturing: Moderately flexible, designed for repetition

- Typical Industries

- Metal fabrication: Common in construction, aerospace, energy

- Manufacturing: Widely used in electronics, automotive, consumer goods

- Common Materials

- Metal fabrication: Primarily metals

- Manufacturing: Metals, plastics, and composite materials

What is Manufacturing?

While metal fabrication is a component of production, manufacturing represents the broader umbrella under which fabrication falls. Manufacturing includes the mass production of goods using a variety of raw materials—not just metal.

What is Manufacturing in Industry?

Manufacturing involves converting raw materials into finished products on a larger scale using both manual and automated processes. Unlike fabrication, which focuses primarily on metal, manufacturing spans multiple material types including plastics, wood, textiles, and electronics.

From smartphone production to food packaging, manufacturing is the backbone of consumer and industrial supply chains.

Types of Manufacturing Processes

- Machining: Similar to fabrication, includes drilling, milling, and turning materials.

- Casting: Pouring liquid material into a mold to harden into a shape.

- Injection Molding: Common in plastic part production; involves injecting material into a mold.

- 3D Printing: An additive process using digital design files and polymers or metals.

- Assembly Lines: Repetitive, large-scale product assembly using automation and human labor.

Tools and Technologies in Manufacturing

Modern manufacturing relies heavily on automation and robotics. Equipment includes:

- Conveyor belts and pick-and-place robots

- Automated guided vehicles (AGVs)

Programmable Logic Controllers (PLCs) - Robotic arms and CNC machines

- IoT-enabled monitoring systems

Examples of Manufactured Goods

- Automobiles and vehicle components

- Household appliances and electronics

- Clothing and packaged food

- Consumer tech like smartphones and laptops

Manufacturing facilities can range from small machine shops to massive factories like Tesla’s Gigafactory that integrate AI and advanced robotics.

Key Differences Between Fabrication and Manufacturing

Though related, there are clear and important distinctions between these two processes:

- Scope

- Metal Fabrication: Specializes in shaping metal parts

- Manufacturing: Encompasses full product creation

- Scope

- Materials

- Metal Fabrication: Primarily metals

- Manufacturing: Includes metals, plastics, textiles, and composites

- Scale

- Metal Fabrication: Small-to-medium batch sizes

- Manufacturing: High-volume, mass production

- Process

- Metal Fabrication: Custom, manual, or semi-automated

- Manufacturing: Highly automated and repetitive

- Applications

- Metal Fabrication: Structural components and custom builds

- Manufacturing: End-user products and large-scale supply

Key Insight:

Metal fabrication can be considered a subset of manufacturing, often serving as a stage in the broader manufacturing process, especially when products require custom metal components.

How They Work Together in Industry

In many industrial workflows, metal fabrication feeds into manufacturing. A fabricated metal part—like a machine bracket or chassis—may be just one component in a larger manufactured product.

Real-World Example:

A company that manufactures HVAC systems might rely on a fabrication shop to produce custom sheet metal casings and support frames. Once fabricated, these components are delivered to the manufacturer for final assembly along with plastic ducts, wiring, and sensors.

Why This Matters:

Understanding how fabrication and manufacturing intertwine can help businesses make more strategic decisions when sourcing parts or scaling production. Partnering with a fabricator like Red River can significantly reduce lead times and improve quality in manufactured products.

Making Sense of Fabrication vs. Manufacturing

In today’s industrial ecosystem, understanding the difference between metal fabrication and manufacturing is more than academic—it’s a key to operational efficiency. While both processes deal with turning raw materials into functional products, they serve different purposes:

- Metal fabrication focuses on the custom, precision creation of metal components.

- Manufacturing is about mass-producing a wide range of products using multiple materials.

Together, they form a dynamic partnership in product development, supporting everything from skyscrapers and cars to smartphones and industrial equipment. Whether you’re building infrastructure or launching a new tech product, understanding both processes will help ensure that your vision is brought to life efficiently and effectively.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions (FAQ)

1. Is metal fabrication considered manufacturing?

Yes. Metal fabrication is a specialized branch of manufacturing focused on the transformation of metal into usable parts.

2. What industries use metal fabrication the most?

Industries like construction, automotive, aerospace, energy, and defense frequently rely on metal fabrication for essential components.

3. Can you fabricate materials other than metal?

While “fabrication” typically refers to metals, similar methods exist for plastics and composites, but those processes are generally called molding or forming.

4. What’s the main goal of manufacturing?

Manufacturing’s primary goal is to produce goods at scale with consistent quality and efficiency. It includes assembling components—some of which may be fabricated—to complete a final product.

5. What tools are used in metal fabrication?

Fabricators use welders, cutters, CNC machines, press brakes, and other metal-specific machinery for precision work.

6. What is the difference between a fabricator and a manufacturer?

A fabricator crafts parts, typically from metal, using shaping and assembly processes. A manufacturer may use these parts—and others—to produce final consumer or industrial products.

7. Is welding part of metal fabrication?

Absolutely. Welding is one of the core techniques in fabrication, allowing separate metal pieces to be securely joined.

8. What’s an example of fabrication in manufacturing?

A fabricated metal engine mount being installed into a manufactured vehicle is a prime example of how the two processes intersect.

Key Takeaways

- Metal fabrication involves shaping, cutting, and assembling metal parts—often for use in larger products.

- Manufacturing is a broader process of creating goods from various materials on a mass scale.

- Fabrication is often a critical component of the manufacturing workflow.

- Both processes require unique skillsets, machinery, and planning.

- Knowing the difference helps businesses choose the right partners and processes for production success.

Table of Contents

ToggleRelated Blog Post

- What trade is metal fabrication?

- Is welding a type of fabrication?

- What is a metal workshop called?

- What are 5 examples of fabrication?

- What are the 3 main fabrication techniques?

- What is the process of making metal called?

- What is the 6 most common types of metal working?

- What are four common materials used in metal fabrication?

- What is the difference between sheet metal and fabrication?

- What is the difference between machinist and metal fabrication?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.