Robotic Welding Implementation: Key Steps and Best Practices

Traditional manual welding, while essential and highly skilled, presents inherent challenges in large-scale manufacturing environments. Consistency across lengthy welds, welder fatigue during repetitive operations, and the physical demands of certain welding positions all impact production. To combat these challenges, Robotic Welding Implementation is becoming more common. Additionally, the industry faces a growing shortage of qualified welders, with the American Welding Society projecting a deficit of 375,000 welders by 2026.

The Manufacturing Challenge: Why Red River Needed Automation

Like many American manufacturers, Red River faced multiple challenges that threatened to constrain our growth and ability to serve customers effectively. Our production floor was experiencing significant bottlenecks, particularly in welding operations for our pressure vessels. As demand increased, these constraints became more pronounced, extending lead times and putting pressure on our skilled workforce.

These combined factors made a compelling case for exploring automation solutions that could complement our skilled workforce while addressing production challenges.

Planning the Robotic Welding Implementation

Evaluating Production Requirements and Automation Opportunities

Our robotic welding implementation journey began with a comprehensive analysis of our production processes. We formed a cross-functional team including welding engineers, production managers, quality personnel, and experienced welders to identify which applications would benefit most from automation.

The team conducted time studies on various welding operations, documented quality variation, and assessed repetitiveness. This analysis revealed that approximately 60% of our robotic welding implementation or operations involved standardized, repetitive welds that were prime candidates for automation. The remaining 40% required the expertise and adaptability of our skilled welders due to complex geometries or variable conditions.

Selecting the Right Robotic Systems for Pressure Vessel Fabrication

Selecting the appropriate robotic welding system proved to be a critical decision point. Our team evaluated multiple vendors based on several criteria:

- Programming flexibility for our diverse product range

- Reach and payload capacity for large pressure vessel components

- Integration capabilities with existing equipment

- Technical support and training programs

- Track record in similar manufacturing environments

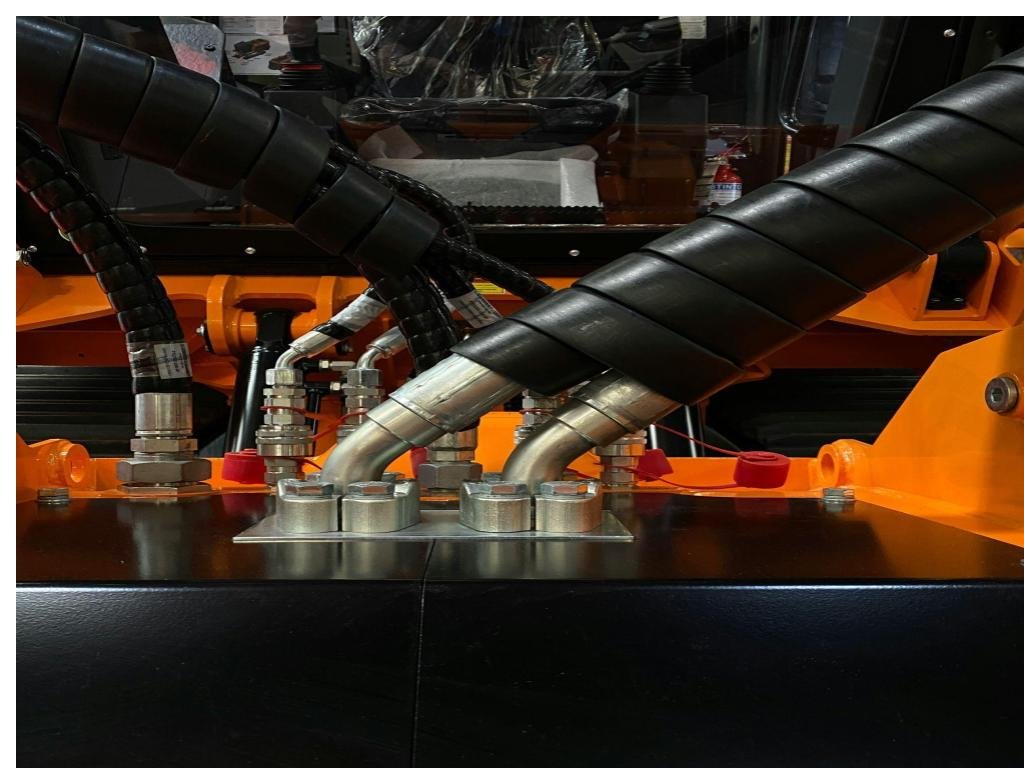

After extensive research and site visits to operational installations, we selected a system featuring articulated arm robots with specialized welding packages designed for heavy fabrication. The selected system included advanced seam tracking capabilities essential for maintaining quality on long welds characteristic of pressure vessel manufacturing.

Preparing the Manufacturing Floor for Integration

Implementing robotic welding implementation cells required significant preparation beyond simply installing the equipment. We reconfigured a 5,000-square-foot section of our manufacturing floor, improving material flow and creating dedicated spaces for the robotic cells and their supporting infrastructure.

Critical infrastructure improvements included:

- Enhanced power supply systems

- Compressed air and shielding gas distribution

- Concrete foundations for the robotic cells

- Safety barriers and light curtains

- Network connectivity for programming and monitoring

Training Personnel for the Transition to Automated Welding

Perhaps the most crucial element of our robotic welding implementation strategy was comprehensive personnel training. We identified team members with strong technical aptitude and welding knowledge to become robot operators and programmers. These individuals completed specialized training programs provided by the robot manufacturer, supplemented by on-site training with our specific applications.

The Implementation Process: From Installation to Full Production

Initial Setup and Calibration Phase

Following equipment delivery, our team worked closely with the vendor’s technical specialists during the four-week installation and calibration phase. This involved mechanical assembly, electrical connections, software configuration, and initial programming of basic welding patterns.

The calibration process was particularly critical for pressure vessel applications, where precise welding parameters directly impact structural integrity. We documented baseline settings for different material thicknesses and joint configurations, creating a library of proven parameters for future use.

Pilot Testing Period and Refinements

Rather than immediately transitioning high-volume production to the robotic welding implementation systems, we implemented a strategic pilot testing program. We selected representative components with moderate complexity and ran small production batches, conducting comprehensive quality testing on each component.

This methodical approach revealed several opportunities for refinement:

- Fixturing modifications to improve part positioning consistency

- Program adjustments to optimize travel speed and dwell times

- Enhanced gas shielding for certain joint configurations

- Modifications to our part preparation processes

Scaling to Full Production Capacity

With refinements completed and verified, we gradually increased production volumes through the robotic cells. This phased approach allowed our team to build confidence in the systems while providing time to develop standardized operating procedures and troubleshooting guides.

Within four months of initial installation, the robotic welding implementation cells were handling approximately 70% of their targeted production volume, with continued scaling as programming libraries expanded and operator proficiency increased.

Continuous Improvement Initiatives

From the beginning, we established that robotic welding implementation was not a one-time event but an ongoing process of refinement. We created a dedicated continuous improvement team that meets weekly to review performance metrics, identify enhancement opportunities, and robotic welding implementation incremental improvements to our automated processes.

Measuring Success: Production Metrics Before and After

Productivity Improvements

The impact of our robotic welding implementation has been substantial across multiple performance indicators:

- 35% overall increase in welding productivity for applicable components

- 42% reduction in production lead time for standard pressure vessels

- 28% improvement in overall equipment effectiveness (OEE)

- Capacity to handle 20% production volume increase without additional labor

Quality Control Outcomes

Quality improvements have been equally impressive:

- 65% reduction in weld defect rates on automated applications

- 89% decrease in rework requirements for standard components

- Enhanced consistency in critical weld parameters

- Improved documentation through automated parameter recording

Return on Investment Analysis

Our financial analysis confirmed the solid business case for automation:

- Initial capital investment recovered within 18 months

- 24% reduction in cost per weld for automated applications

- Decreased overtime expenses by redistributing labor to day shifts

- Reduced consumable usage through optimized robotic welding implementation parameters

Employee Adaptation and Skill Development

Perhaps most gratifying has been witnessing our team’s adaptation to the new technology:

- Six welders successfully transitioned to robot operator/programmer roles

- Enhanced job satisfaction through reduced physical strain

- Creation of new technical career paths within our organization

- Improved ability to focus skilled welders on complex, high-value tasks

Robotic Welding Implementation: Red River’s Journey to Enhanced Productivity

Red River’s strategic adoption of robotic welding implementation technology represents a transformative milestone in their manufacturing evolution. The robotic welding implementation has not only enhanced efficiency but also ensured precision in every weld, significantly contributing to the superior quality of their fabricated products. The benefits have been multifaceted and substantial. By automating critical welding processes, Red River has dramatically reduced workplace hazards, with robotic systems now handling dangerous tasks that previously posed risks to human workers

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. How long did Red River’s robotic welding implementation take from planning to full operation?

The complete robotic welding implementation process took approximately 9 months, with 3 months for planning and selection, 2 months for installation and initial programming, and 4 months of graduated production scaling and optimization.

2. What types of welds were successfully automated at the Red River facility?

Red River successfully automated circumferential seam welds on pressure vessel shells, longitudinal seams on vessel sections, and repetitive attachment welds for nozzles and supports where access permitted robotic tooling.

3. How did Red River address the challenge of programming complex weld paths?

The robotic welding implementation team utilized a combination of offline programming software for standard components and teach-pendant programming for more complex applications, with master programs that could be modified for similar part families.

4. What was the role of Red River’s manual welders after automation?

Manual welders transitioned to more specialized roles handling complex joints unsuitable for automation, performing quality verification, and developing robotic welding implementation procedures. Several welders received training to become robot operators and programmers.

5. How did Red River calculate the return on investment for the robotic welding cells?

ROI calculations incorporated productivity increases, reduced rework, decreased overtime costs, and the ability to reassign skilled welders to higher-value tasks. The system achieved full ROI within 18 months of implementation.

6. What unexpected challenges emerged during the robotic welding implementation process?

Unforeseen challenges included longer-than-anticipated programming time for complex parts, fixturing modifications required for consistent part positioning, and integration with existing material handling systems.

Key Takeaways

- Robotic welding implementation complements rather than replaces skilled manual welders

- Initial programming investment delivers long-term productivity gains

- Employee training and involvement significantly impact robotic welding implementation success

- Continuous improvement processes maximize automation benefits over time

- Quality improvements can exceed productivity gains in overall value