Understanding Boilers as Pressure Vessels

Table of Contents

ToggleIntroduction to Boilers and Pressure Vessels

A boiler, in its essence, is a vessel that heats water or any other type of fluid under controlled conditions. The heated or vaporized fluid exits the boiler for use in various processes or heating applications. But here’s the key question: is a boiler a pressure vessel? Absolutely! Boilers operate under pressure to generate steam or hot water, fitting the definition of a pressure vessel. Therefore, at Red River, we recognize the importance of these systems in your operations and are dedicated to providing the highest quality and safety in our boiler manufacturing.

Defining Pressure Vessels

Pressure vessels, as the name suggests, are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. In fact, they are a critical component in industries like oil and gas, power generation, and biogas, to name a few. For this reason, our expertise at Red River lies in crafting these vessels with precision, ensuring they adhere to stringent safety standards while meeting your specific needs.

The Role of Boilers in Industrial Applications

Boilers are more than just components; they are the heart of many industrial processes. For example, in sectors like power generation, commercial works, and minerals/elements processing, boilers play a pivotal role. They are not just equipment; they are the lifeline of your operations. As a result, at Red River, we understand this significance. That’s why we don’t just manufacture boilers; we engineer solutions that integrate seamlessly into your operations, ensuring efficiency, safety, and reliability.

Boiler Design and Pressure Vessel Standards

Boiler Design and Pressure Vessel Standards

Boilers, by their very nature, are designed to operate under pressure, making them a subset of pressure vessels. Moreover, the design and manufacturing of boilers are governed by specific standards to ensure safety and efficiency. These standards, often set by authoritative bodies like the ASME, dictate the materials, design, and construction methods to be used. Consequently, at Red River, we ensure compliance with these standards to deliver products you can rely on.

Types of Boilers and Their Classification

Boilers come in various types, each classified based on their purpose, design, and operating principles. For instance, from fire-tube to water-tube, each type has unique characteristics but shares the common trait of functioning under pressure. Therefore, understanding their classification is essential for selecting the right boiler for specific industrial needs.

Legal Definitions and Industry Norms

Legally, boilers are recognized as pressure vessels across many jurisdictions. As a result, this classification subjects them to specific industry norms and regulations, ensuring their safe operation in various industrial settings. In addition, adhering to these norms helps maintain compliance with safety standards.

Safety Regulations for Boilers as Pressure Vessels

Understanding ASME Boiler and Pressure Vessel Code

The ASME Boiler and Pressure Vessel Code is a key regulatory standard that provides guidelines for the design, manufacture, and inspection of boilers and pressure vessels. Thus, it ensures safety and reliability. Moreover, following this code is critical for meeting industry expectations and avoiding potential risks.

Safety Measures and Compliance

Adhering to safety measures and compliance is crucial. This includes implementing fail-safes, pressure relief systems, and regular safety audits to prevent accidents. Consequently, these measures protect both equipment and personnel in industrial operations.

Regular Inspections and Maintenance Requirements

Regular inspections and maintenance are vital for the longevity and safe operation of boilers. For example, these practices help identify potential issues before they escalate into major problems. Additionally, routine checks ensure that the equipment performs optimally over its lifespan.

The Technical Aspects of Boilers as Pressure Vessels

Construction Materials and Design Principles

The construction of boilers involves robust materials and design principles that can withstand high pressure and temperatures. As a result, this ensures durability and safety. In conclusion, high-quality construction is fundamental to the efficiency and reliability of boilers in demanding industrial environments.

Pressure Control and Safety Mechanisms

Incorporating effective pressure control and safety mechanisms is essential in boiler design to manage and mitigate the risks associated with high-pressure operations.

Advances in Boiler Technology

Technological advancements in boiler design and materials have significantly improved their efficiency, safety, and environmental impact.

The Role of Boilers in Various Industries

Boilers in the Energy Sector

In the energy sector, boilers are indispensable for power generation, playing a critical role in driving industry operations.

Applications in Manufacturing Industries

Boilers are pivotal in manufacturing industries, providing the necessary steam or heat for various processes.

Importance in the Healthcare Sector

In healthcare, boilers are crucial for sterilization processes and maintaining environmental conditions, underscoring their versatility.

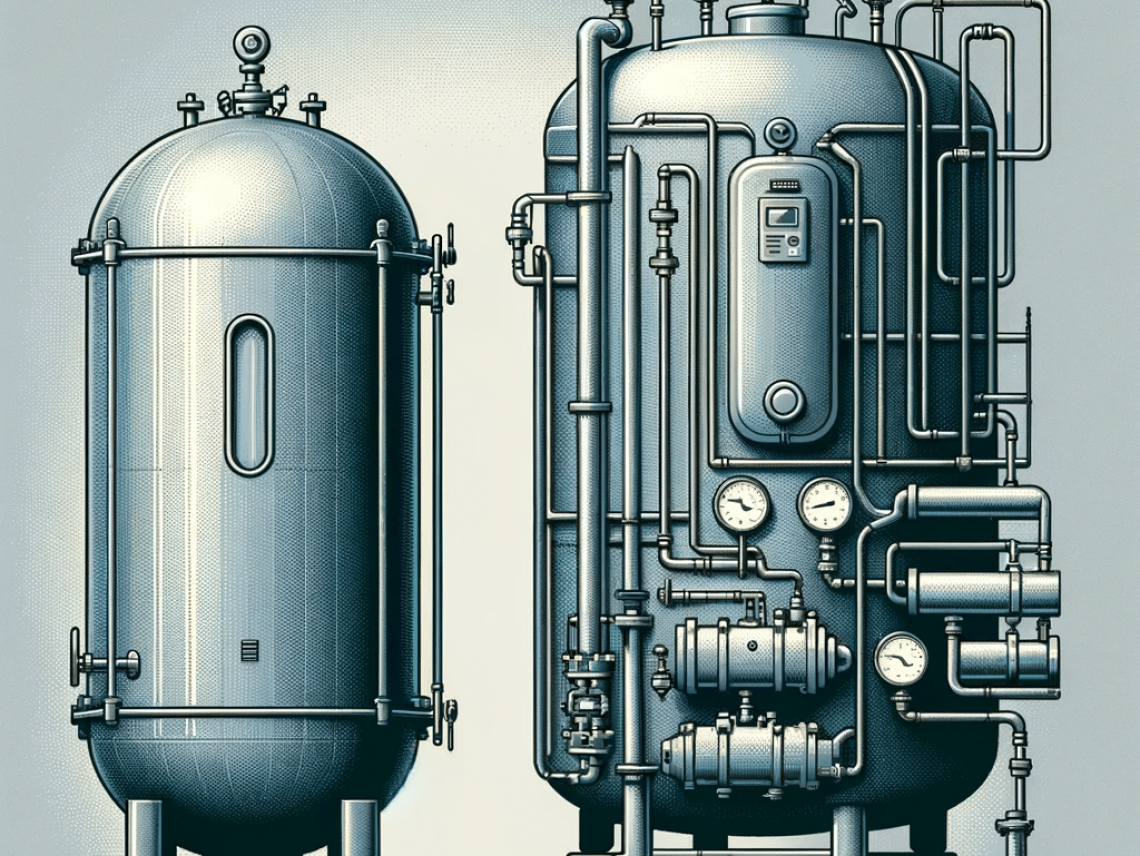

Comparing Boilers with Other Pressure Vessels

Similarities and Differences

While boilers share similarities with other pressure vessels in terms of design and function, they also have distinct differences, particularly in their specific applications.

Use Cases of Different Pressure Vessels

Different pressure vessels serve varied purposes across industries, from storage to reaction processes, each designed to meet specific operational needs.

Specialized Pressure Vessels in Industry

Specialized pressure vessels are tailored for specific industry requirements, demonstrating the diverse applications and importance of these systems in modern industry.

Boiler Efficiency and Environmental Considerations

Energy Efficiency in Boiler Design

Modern boiler designs prioritize energy efficiency, reducing operational costs and environmental footprint. Innovations in heat recovery and fuel utilization contribute significantly to this efficiency, making boilers more sustainable.

Reducing Environmental Impact

Reducing the environmental impact of boilers involves minimizing emissions and optimizing fuel consumption. Advances in cleaner-burning fuels and emission control technologies are central to these efforts.

Sustainable Practices in Boiler Operation

Sustainable operation of boilers is achieved through regular maintenance, efficient operation practices, and the use of renewable energy sources where possible, aligning with global environmental goals.

Innovations in Boiler and Pressure Vessel Technology

Emerging Trends in Boiler Design

Emerging trends in boiler design include modular construction, advanced materials, and improved thermal efficiency, reflecting the industry’s push toward innovation and sustainability.

Smart Technology Integration

Integration of smart technologies in boilers, such as IoT and AI, enables predictive maintenance, real-time monitoring, and optimized performance, heralding a new era in boiler operation.

Future of Pressure Vessel Engineering

The future of pressure vessel engineering is marked by advancements in material science, digitalization, and custom engineering solutions, driving the industry towards more efficient and safer practices.

Legal and Insurance Aspects of Boilers as Pressure Vessels

Navigating Boiler Insurance Policies

Understanding and navigating boiler insurance policies is crucial for risk management, covering potential damages, and ensuring compliance with industry standards.

Legal Responsibilities of Boiler Operators

Boiler operators must adhere to legal responsibilities, including compliance with safety regulations and operational standards, to ensure safe and efficient boiler operation.

Risk Management in Boiler Operation

Effective risk management in boiler operation involves regular safety audits, adherence to operational protocols, and staying updated with regulatory changes.

Choosing the Right Boiler for Your Needs

Factors to Consider When Selecting a Boiler

Selecting the right boiler involves considering factors like capacity, efficiency, fuel type, and application-specific requirements, ensuring optimal performance and cost-effectiveness.

Consulting with Experts at Red River LLC

Consulting with Red River LLC’s experts ensures informed decision-making, leveraging their experience and knowledge in boiler technology and industry needs.

Custom Solutions for Unique Requirements

Red River LLC specializes in providing custom boiler solutions tailored to unique operational requirements, ensuring clients receive the most suitable and efficient systems for their specific needs.

Need a reliable partner?

Frequently Asked Questions About Pressure Vessels

What are the key factors to consider when selecting materials for pressure vessel construction?

Selecting the right materials for pressure vessel construction is crucial for safety, efficiency, and longevity. Key factors include the vessel’s operating temperature and pressure, the type of substance it will contain (e.g., corrosive or non-corrosive fluids), and environmental conditions. Materials commonly used include carbon steel, stainless steel, and alloys like Hastelloy or Inconel, each offering different strengths and resistance to corrosion and temperature.

How do pressure vessels handle extreme temperatures and pressures?

Pressure vessels are designed to withstand extreme conditions through robust construction and engineering. They are equipped with features like thick walls, reinforced joints, and safety valves. The design also considers thermal expansion and contraction. Advanced computational methods and rigorous testing ensure that they can handle specified temperature and pressure ranges safely.

What are the most common applications of pressure vessels in industry?

Pressure vessels have a wide range of applications across various industries. In the oil and gas industry, they are used for storage and processing under high pressure. In power generation, they are essential in steam boilers. The chemical industry uses them for reactions and storage of gases and liquids under pressure. Additionally, they are vital in pharmaceuticals for sterilization processes and in the food and beverage industry for processing and storage.

Can pressure vessels be custom-designed for specific industrial needs?

Yes, pressure vessels can be custom-designed to meet specific industrial requirements. This customization can include size, shape, material, internal components, and pressure ratings. Custom designs are essential for industries with unique processes or space constraints. Working with an experienced manufacturer is crucial for ensuring that the custom vessel meets all safety and operational standards.

What are the latest advancements in pressure vessel technology?

Recent advancements in pressure vessel technology focus on improving safety, efficiency, and environmental sustainability. These include the use of lighter, more durable materials, the integration of smart sensors for real-time monitoring and predictive maintenance, and advancements in welding and fabrication techniques for better quality control. Additionally, there’s a growing trend towards eco-friendly designs, such as using materials and processes that minimize environmental impact.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.