Understanding Scrubber Vessels in the Industry

Table of Contents

ToggleWhat is the industrial use of scrubber vessels?

Importance of Scrubber Vessels in Industrial Processes

The significance of scrubber vessels in industrial operations can’t be overstated. They aid in mitigating air pollutants, selling regulatory compliance, and fostering a safer working surroundings. By efficaciously disposing of dangerous substances, scrubber vessels make contributions to environmental sustainability and public fitness protection.

Overview of Scrubber Vessel Designs

Scrubber vessels efficiently capture and neutralize pollution, substantially reducing the emission of harmful materials which includes sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate rely. This proactive method aids in combating air pollutants and its unfavourable results on public fitness and the environment.

Benefits of Utilizing Scrubber Vessels in Industrial Operations

Reduction of Air Pollution

Scrubber vessels effectively capture and neutralize pollutants, significantly reducing the emission of harmful substances such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. This proactive approach aids in combating air pollution and its adverse effects on public health and the environment.

Compliance with Environmental Regulations

In today’s stringent regulatory environmental compliance landscape, adherence to environmental standards is paramount for industrial facilities. Scrubber vessels facilitate compliance with emission regulations imposed by local authorities and regulatory agencies, ensuring that operations meet legal requirements while minimizing environmental impact.

Enhancement of Workplace Safety

By removing hazardous substances from exhaust gases, scrubber vessels contribute to creating a safer working environment for industrial personnel. Reduced exposure to pollutants helps mitigate health risks associated with occupational exposure, fostering employee well-being and productivity.

Types of Scrubber Vessels Used in Industry

Wet Scrubber Vessels

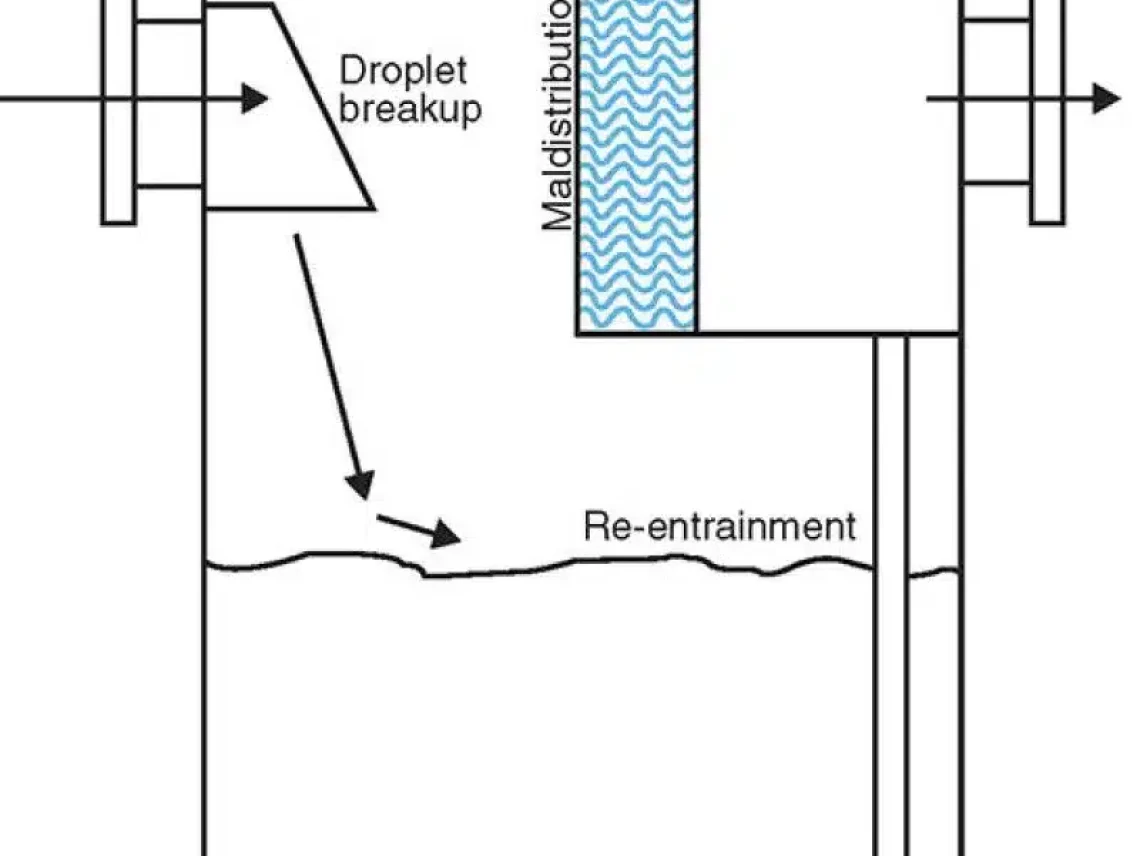

Wet scrubbers utilize liquid solutions to capture and neutralize pollutants present in industrial exhaust streams. These versatile systems are effective in removing a wide range of contaminants, including acidic gases, particulate matter, and volatile organic compounds (VOCs).

- How Wet Scrubbers Work

- Applications of Wet Scrubbers

Dry Scrubber Vessels

Dry scrubbers employ sorbent materials or reactive agents to chemically react with and capture pollutants from exhaust gases. These systems offer advantages such as lower water consumption and reduced wastewater generation compared to wet scrubbers.

- Operating Mechanism of Dry Scrubbers

- Advantages of Dry Scrubbers

Need a reliable partner?

FAQ’s

Q: What are the main pollutants that scrubber vessels can remove from industrial exhaust gases?

A: Scrubber vessels are adept at removing a variety of pollutants from industrial exhaust gases, including sulfur dioxide (SO2), nitrogen oxides (NOx), particulate matter, volatile organic compounds (VOCs), and hazardous air pollutants (HAPs). Through efficient scrubbing mechanisms, these vessels play a crucial role in reducing emissions and promoting environmental sustainability.

Q: How do wet scrubber vessels differ from dry scrubber vessels in terms of operation and effectiveness?

A: Wet scrubber vessels utilize liquid solutions, such as water or chemical reagents, to capture and neutralize pollutants through absorption, adsorption, or chemical reactions. Conversely, dry scrubber vessels employ sorbent materials or reactive agents to chemically react with and capture contaminants from exhaust gases. While both types have their advantages, wet scrubbers are typically more effective in removing a broader range of pollutants, whereas dry scrubbers offer benefits such as lower water consumption and reduced wastewater generation.

Q: What factors should be considered when selecting the appropriate scrubber vessel for an industrial application?

A: Several factors should be taken into account when choosing a scrubber vessel, including the type and concentration of pollutants in the exhaust gas, the desired level of emission control, the available space for installation, operational requirements, and budget constraints.

Q: Are there any regulatory standards or requirements that industrial facilities must comply with regarding scrubber vessel installations?

A: Yes, industrial facilities are subject to various regulatory standards and emissions limits imposed by local authorities and regulatory agencies, such as the Environmental Protection Agency (EPA) in the United States. These regulations dictate permissible emission levels for pollutants and often require the implementation of emission control technologies, including scrubber vessels, to ensure compliance.

Q: What are some common maintenance procedures required for scrubber vessels, and how can industrial operators ensure optimal performance and longevity?

A: Regular maintenance is critical for ensuring the efficient operation and longevity of scrubber vessels. Common maintenance procedures include monitoring and replenishing scrubbing media, inspecting and cleaning components such as nozzles, mist eliminators, and packing materials, checking for leaks or corrosion, and conducting performance evaluations through emission testing and analysis.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.