Understanding the Advantage of Pressurized Water Reactors with Red River LLC

Table of Contents

ToggleIntroduction to Pressurized Water Reactors

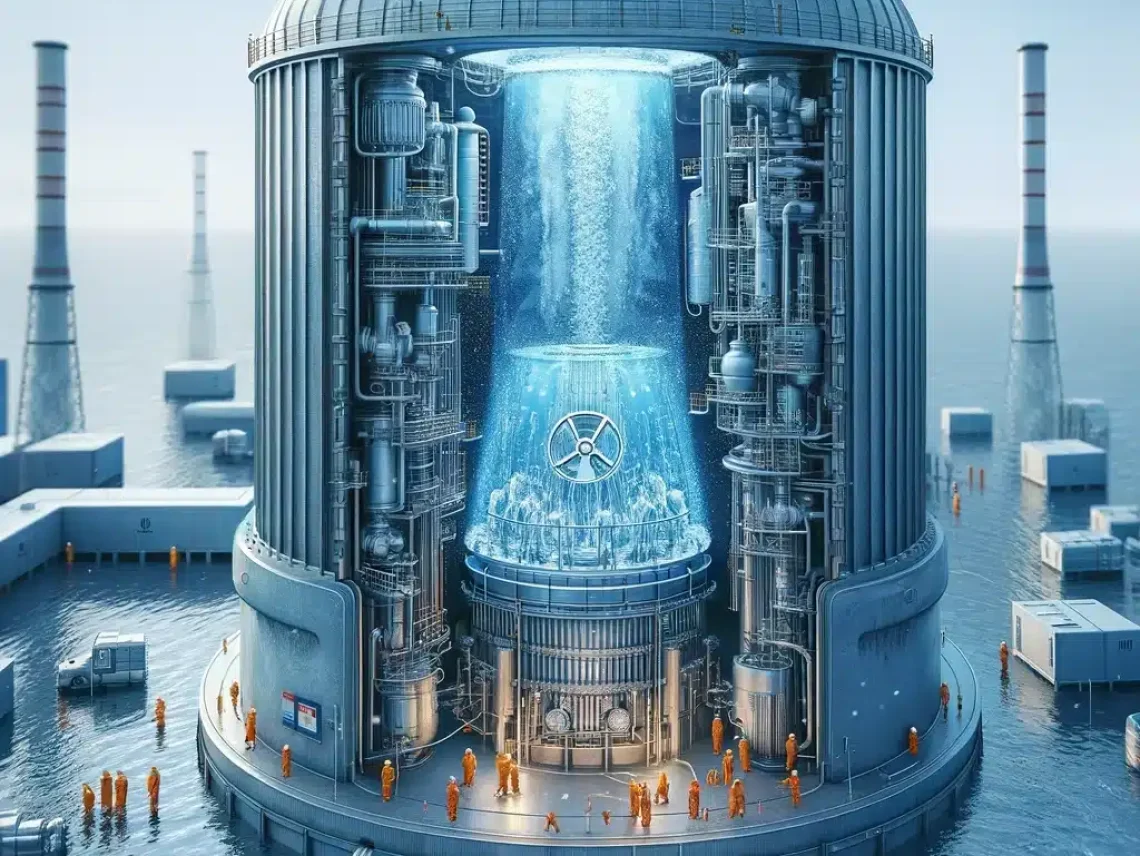

At the heart of many power generation systems lies the pressurized water reactor (PWR), a marvel of modern engineering. But what exactly is a PWR? Simply put, it’s a type of nuclear reactor that uses pressurized water as both a coolant and a neutron moderator. This dual role allows the reactor to maintain temperatures at a safe level while efficiently producing energy. At Red River LLC, we’ve been at the forefront of pressure vessel manufacturing, and our expertise extends to the intricacies of PWRs. We understand the unique benefits of pressurized water reactor technology and how it stands out in the realm of nuclear power.

History and Evolution of PWR Technology

The journey of PWRs began in the mid-20th century, and since then, they’ve become a cornerstone in the nuclear energy sector. Initially developed for naval propulsion, their efficiency and safety features soon caught the attention of the power generation industry. Over the years, the technology has evolved, with continuous improvements enhancing its safety and performance metrics. At Red River LLC, we value the work ethic and dedication that has driven this evolution. Just as the pioneers of PWR technology were committed to innovation, we too are dedicated to pushing boundaries in the industries we serve, from oil and gas to power generation and beyond.

The Role of PWRs in Modern Nuclear Energy

In today’s energy landscape, PWRs play a pivotal role. They are among the most common types of nuclear reactors globally, and for a good reason. The key strengths of pressurized water reactors lie in their safety and efficiency. Their design ensures that the reactor remains in a subcritical state, preventing any potential meltdowns. Moreover, their ability to operate at high pressures means they can produce steam directly, eliminating the need for boilers and steam generators.

But why choose a pressurized water reactor? The answer is simple: they offer unparalleled advantages in nuclear energy production. Their design ensures optimal safety, their efficiency is unmatched, and their adaptability makes them suitable for various applications. At Red River LLC, we understand the merits of PWRs. Our commitment to American values, combined with our dedication to safety and quality, means we’re uniquely positioned to serve the needs of those looking to harness the benefits of pressurized water reactors.

Key Strengths of Pressurized Water Reactors

Primary Advantage of Using PWRs

PWRs stand out due to their dual-purpose design: using pressurized water as both a coolant and neutron moderator. This ensures optimal temperature control, leading to efficient energy production.

Safety Features Unique to PWRs

Safety is paramount in nuclear energy. PWRs are designed with multiple safety barriers, ensuring the containment of radioactive materials and preventing potential meltdowns.

Efficiency and Performance Metrics

With their ability to operate at high pressures, PWRs can produce steam directly, eliminating the need for secondary equipment and enhancing overall efficiency.

Comparing PWRs to Other Reactor Types

PWR vs. Boiling Water Reactor (BWR)

Pressurized Water Reactors (PWRs) and Boiling Water Reactors (BWRs) are both light water reactors, but they differ in their approach to cooling and steam generation. In a BWR, water boils inside the reactor vessel, producing steam directly for the turbine. In contrast, a PWR keeps water under high pressure to prevent it from boiling within the reactor. This allows for a separate steam generator that transfers heat, leading to a more direct and efficient energy conversion in PWRs.

PWR vs. Fast Breeder Reactor (FBR)

While PWRs rely on slow (thermal) neutrons, Fast Breeder Reactors (FBRs) utilize fast neutrons and have a closed fuel cycle. This allows FBRs to generate more fuel than they consume, making them efficient but complex. PWRs, on the other hand, offer operational simplicity and safety, without the complexities of fast neutron handling, making them widely used in commercial power production.

PWR vs. Heavy Water Reactor (HWR)

Heavy Water Reactors (HWRs) use heavy water (deuterium oxide) as a moderator, allowing them to use natural uranium as fuel. PWRs, with their light water design, generally require enriched uranium but benefit from a more compact and cost-effective reactor structure. The design differences provide unique advantages in terms of cost and fuel availability, with PWRs often favored for their simplicity and HWRs for their fuel efficiency.

The Science Behind PWR Efficiency

How Pressurization Enhances Reactor Performance

The pressurization of water in a PWR keeps it from boiling at high temperatures, enabling the reactor to operate under greater thermal efficiency. By preventing boiling, the reactor maintains stable conditions and transfers heat more effectively, enhancing overall performance. This setup allows PWRs to reach higher temperatures, translating to a higher thermal-to-electric conversion efficiency.

Thermal Dynamics of PWRs

PWRs are optimized for efficient heat transfer. The pressurized water in the primary loop flows through the reactor core, absorbing heat and transferring it to the secondary loop via a heat exchanger or steam generator. This heat management and transfer system maximizes the reactor’s ability to convert nuclear energy into electricity, ensuring a steady, efficient output.

The Role of Coolants in PWRs

Coolants in PWRs are crucial for both heat removal and radiation shielding. The primary coolant absorbs heat from the reactor core and transports it to the steam generator, preventing overheating. Additionally, it acts as a radiation shield, protecting reactor components and personnel from radiation exposure. By serving these dual functions, the coolant plays an essential role in ensuring safety and sustaining high performance within PWR systems.

Safety Protocols in Pressurized Water Reactors

Inherent Safety Design of PWRs

PWRs are designed with inherent safety features, ensuring the reactor remains in a subcritical state and preventing potential meltdowns.

Emergency Shutdown Procedures

In case of anomalies, PWRs have swift shutdown procedures, ensuring immediate cessation of the nuclear reaction.

Radiation Containment Measures

PWRs are equipped with robust containment structures, ensuring that no radiation leaks into the environment, and safeguarding both personnel and the surroundings.

Environmental Benefits of PWRs

Reduced Carbon Footprint

PWRs offer a cleaner energy alternative, significantly reducing greenhouse gas emissions compared to fossil fuel-based power sources, thus mitigating global warming impacts.

Sustainable Nuclear Energy Production

With abundant fuel sources and efficient energy conversion, PWRs provide a sustainable solution, meeting growing energy demands without depleting resources.

Waste Management and Disposal

Modern PWRs are designed with advanced waste management systems, ensuring safe, compact, and long-term disposal, minimizing environmental risks.

Real-world Applications of PWRs

PWRs in Power Plants Worldwide

Globally, PWRs are the reactor of choice in many nuclear power plants, a testament to their efficiency, safety, and reliability.

Case Study: Successful PWR Implementations

From Europe to Asia, numerous power plants have showcased the successful integration and operation of PWRs, setting benchmarks in nuclear energy production.

Innovations and Future of PWRs

The future holds promise with continuous advancements in PWR technology, aiming for even greater efficiency and safety.

Why Red River LLC Champions PWR Technology

Our Commitment to Sustainable Energy

At Red River LLC, we believe in a greener future. Championing PWRs aligns with our vision of sustainable, efficient, and clean energy.

Red River's PWR Projects and Achievements

Our portfolio boasts successful PWR projects, reflecting our expertise and commitment to excellence in nuclear energy solutions.

Client Testimonials and Success Stories

Our client’s success stories and testimonials underscore our dedication and the transformative impact of PWR implementations.

Making the Switch to PWRs: A Guide

Evaluating the Feasibility of PWR Implementation

Considering a switch? We help evaluate the feasibility, ensuring a seamless transition to PWR technology.

Cost-Benefit Analysis of PWR Adoption

Delve into a comprehensive analysis, weighing the long-term benefits against the initial investment in PWRs.

Steps to Transitioning to PWR Technology

From planning to execution, we guide you through every step, ensuring a smooth transition to the world of PWRs.

Need a reliable partner?

FAQ: Understanding Pressure Vessels and Their Importance

What exactly is a pressure vessel?

A pressure vessel is a container specifically designed to hold gases or liquids at a pressure that’s significantly different from the ambient pressure. These vessels are used in a variety of industries, including oil and gas, power generation, and chemical processing, to name a few. Their design ensures that they can safely contain substances under pressure, preventing potential explosions or leaks.

Why is the material selection crucial for pressure vessels?

Material selection is paramount for pressure vessels due to the extreme conditions they often operate under. The right material ensures the vessel can withstand high pressures, temperatures, and potential corrosive substances. Common materials include carbon steel, stainless steel, and other alloy materials. The choice often depends on the specific application, the substance contained, and the operating conditions.

How do pressure vessels differ from boilers?

While both pressure vessels and boilers are designed to contain pressurized substances, boilers are specifically designed to produce steam. This steam can be used for various purposes, including power generation and heating. On the other hand, pressure vessels are more versatile and can be used to store and transport both gases and liquids under pressure.

What safety measures are typically in place for pressure vessels?

Safety is paramount when dealing with pressurized substances. Pressure vessels are equipped with safety valves that release pressure if it exceeds a certain limit. They also undergo regular inspections and testing to ensure their integrity. Additionally, they are designed with multiple layers and barriers to prevent leaks and potential explosions. The design, manufacturing, and operation of pressure vessels are governed by industry standards and regulations to ensure safety.

How does prefabrication benefit pressure vessel manufacturing?

Prefabrication refers to the process of assembling parts or sections of a pressure vessel off-site and then transporting the completed or semi-completed vessel to the site. This method offers several benefits:

- Quality Control: Manufacturing in a controlled environment ensures consistent quality, reducing errors due to environmental factors.

- Efficiency: Without on-site environmental delays, production is faster. Material organization and delivery can also be better synchronized with the production schedule.

- Cost Savings: Prefabrication often results in reduced costs due to the efficiencies gained in a manufacturing environment versus on-site construction.

- Safety: With less on-site fabrication, there’s reduced risk, leading to fewer on-site exposure hours and potential hazards.

Table of Contents

ToggleRelated Blog Post

- Are boilers fired pressure vessels?

- Is a steam turbine a pressure vessel?

- What is the difference between piping and pressure vessel?

- What is the difference between a pressure vessel and a column?

- What is the difference between a surge vessel and a pressure vessel?

- What is the difference between a pressure vessel and a high-pressure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.