Understanding the Theory of Air Vessel | Red River LLC

Table of Contents

ToggleIntroduction to Air Vessel Theory

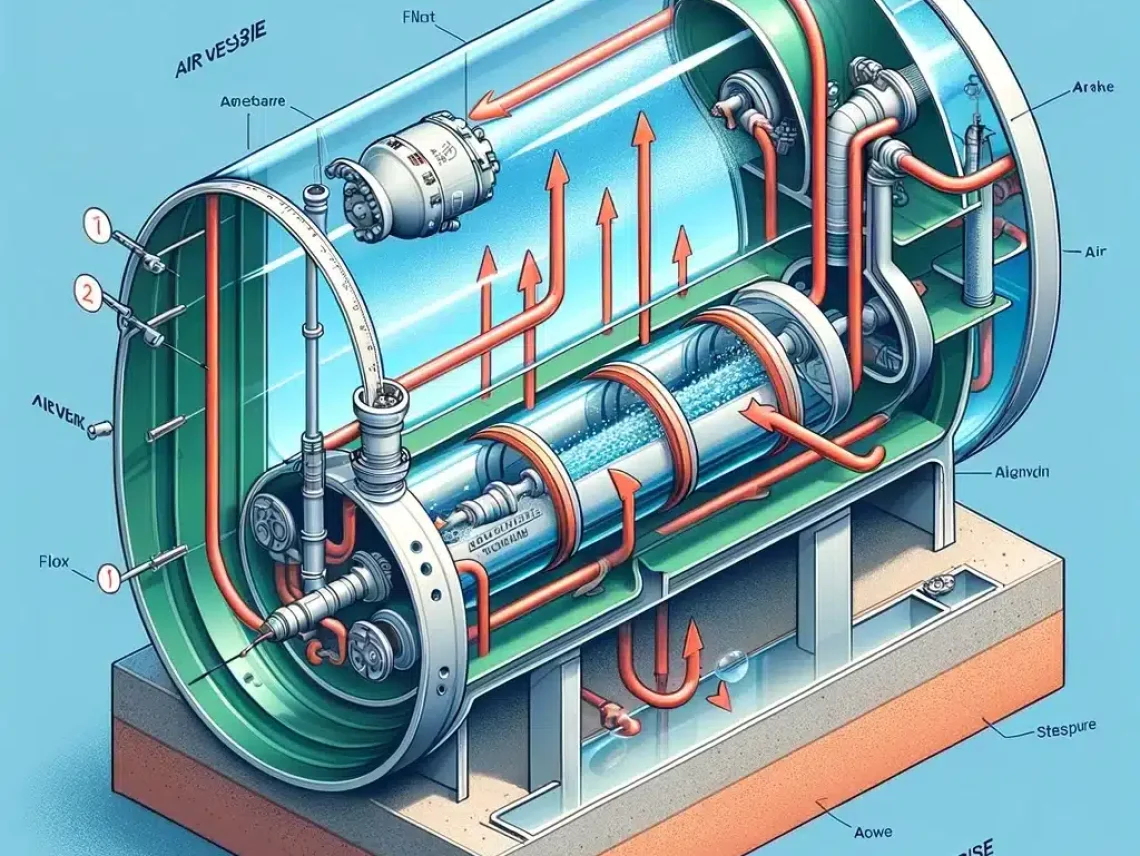

What exactly is an air vessel? Simply put, it’s a device designed to maintain air under pressure, often used to stabilize pressure fluctuations in fluid pumping systems. Moreover, it represents the ingenuity behind air vessel dynamics. At Red River, we recognize air vessels as essential components in the broader landscape of engineering excellence. In addition, these vessels play a vital role in ensuring operational stability and efficiency.

Historical Background of Air Vessel Technology

The concept of air vessels has a long history, evolving over centuries alongside technological advancements. Beginning with early industrial innovations, these vessels have continuously adapted to meet the needs of industries like oil, gas, and energy. Over time, their importance has grown, and their applications have expanded significantly. Furthermore, Red River is proud to continue this legacy, combining a deep appreciation for history with cutting-edge engineering.

Importance and Applications of Air Vessel Theory

Why are air vessels so important? These vessels are indispensable across various industries, including biogas, mineral extraction, and large-scale commercial projects. For example, they stabilize systems, protect against surges, and enhance operational safety. As a result, air vessels play a critical role in improving efficiency and ensuring long-term reliability.

Fundamental Principles of Air Vessel Theory

Basic Concepts in Air Vessel Mechanics

Air vessels function based on the principles of pressure and fluid dynamics. In essence, mastering these principles is critical to producing high-quality air vessels. At Red River, we prioritize understanding these fundamentals to craft vessels that meet the highest standards of performance and durability.

The Role of Pressure in Air Vessels

The principles of pressure are critical to the functionality of air vessels. By incorporating these concepts, we ensure optimal pressure management, which is essential for maintaining machine balance and reducing operational risks. Consequently, stable pressure enhances performance and prevents fluctuations that could disrupt operations.

Understanding Fluid Dynamics in Air Vessels

Fluid dynamics are essential to the performance of air vessels. By leveraging advanced principles, we design vessels that operate seamlessly under various conditions, ensuring reliability and efficiency.

Types of Air Vessels

Characteristics of Different Air Vessel Designs

Our portfolio includes a diverse range of air vessel designs, each featuring custom attributes tailored to meet the specific demands of various industries.

Comparing Rigid and Flexible Air Vessels

Our collection includes both rigid and flexible air vessels, each offering unique advantages based on specific application requirements.

Innovations in Air Vessel Types

Innovation drives our approach to air vessel design, integrating modern technology to achieve superior performance and efficiency.

Air Vessel Design and Construction

Key Components of Air Vessel Design

Every air vessel we design features meticulously chosen components, ensuring unmatched performance and long-lasting durability.

Materials Used in Air Vessel Construction

We utilize only the highest-quality materials to ensure our air vessels withstand even the most demanding conditions.

Advances in Air Vessel Manufacturing Techniques

By employing advanced manufacturing strategies, we ensure precision and excellence in every air vessel we produce. As a result, these techniques set us apart, offering superior quality compared to traditional methods. Furthermore, our state-of-the-art approach guarantees that each vessel meets the unique needs of our clients.

Theoretical Models of Air Vessel Operation

Mathematical Modeling of Air Vessel Dynamics

Through advanced mathematical modeling, we ensure every air vessel operates with optimal efficiency.

Simulation and Analysis of Air Vessel Behavior

Using simulation and evaluation, we accurately predict and enhance the performance of air vessels under diverse conditions.

Case Studies in Air Vessel Operation

Our case studies highlight our proven expertise and achievements across a range of air vessel applications.

Air Vessel Efficiency and Optimization

Techniques for Enhancing Air Vessel Performance

We apply innovative techniques to optimize the performance and reliability of our air vessels.

Energy Efficiency in Air Vessel Design

Energy efficiency remains a core focus in our air vessel designs, reflecting our commitment to sustainability and environmental responsibility.

Sustainability Considerations in Air Vessel Use

Sustainability is a core principle in our design process, ensuring that our air vessels actively contribute to environmental preservation.

Applications of Air Vessel Theory

Air Vessels in Industrial Settings

These systems are critical in industries such as oil and gas, stabilizing pressure fluctuations and enhancing operational efficiency.

Air Vessels in Environmental Engineering

Within the field of environmental engineering, air vessels are instrumental in reducing emissions and promoting sustainable, green operations.

Innovative Uses of Air Vessels in Various Industries

Red River LLC leads the way in innovative air vessel applications, driving advancements across industries such as power generation and biogas production.

Challenges and Solutions in Air Vessel Theory

Addressing Common Issues in Air Vessel Design

We tackle complex design challenges with precision, ensuring every air vessel is tailored to meet specific industry needs.

Overcoming Operational Challenges in Air Vessels

Our expertise enables us to overcome operational challenges, delivering air vessels that prioritize reliability and durability.

Future Directions in Air Vessel Research

We are dedicated to pushing the boundaries of air vessel research, prioritizing innovative solutions and enhanced performance capabilities.

Regulatory and Safety Aspects of Air Vessels

Compliance with Industry Standards

Our air vessels comply with rigorous industry standards, ensuring both safety and high-quality performance.

Safety Protocols for Air Vessel Operation

Ensuring safety is our top priority, supported by robust protocols that guarantee the reliable use of our air vessels.

Certification Processes for Air Vessels

Through comprehensive certification processes, we ensure our air vessels fully comply with regulatory requirements.

Case Studies and Real-World Examples

Success Stories in Air Vessel Implementation

A diverse range of success stories highlights the reliability and effectiveness of our air vessels across various industries.

Lessons Learned from Air Vessel Failures

By analyzing past ventures, we continuously refine our designs and strategies, turning challenges into opportunities for improvement.

Innovations and Breakthroughs in Air Vessel Technology

At Red River LLC, we lead the way in air vessel technology, consistently innovating to address the evolving demands of modern industries.

Need a reliable partner?

Frequently Asked Questions About Pressure Vessels

What are the key factors to consider when selecting materials for pressure vessel construction?

Material selection for pressure vessels is vital and depends on factors just as the running environment, temperature, pressure tiers, and the nature of the materials being contained. Common materials consist of carbon metal for its electricity and affordability, stainless steel for corrosion resistance, and aluminum for lightweight applications. The choice has to align with the vessel’s intended use, making sure protection, sturdiness, and compliance with industry standards.

How do pressure vessels handle extreme temperatures and pressures?

Pressure vessels are designed to face up to intense situations through strong creation and engineering. They are ready with functions like thick walls, strengthened joints, and protection valves. Advanced materials and coatings also can be used to beautify their resistance to excessive temperatures and pressures. Regular inspections and maintenance are crucial to ensure their integrity under such conditions.

What are the most common uses of pressure vessels in the industry?

Pressure vessels have a wide variety of business programs. They are vital within the oil and gas enterprise for storage and processing. In the chemical industry, they may be used for reactions and containment of chemical substances. Power generation flowers are in boilers and reactors. Additionally, they’re essential within the pharmaceutical, meals and beverage, and water treatment industries for numerous processing and storage purposes.

What are the latest advancements in pressure vessel technology?

Recent improvements in pressure vessel generation encompass using composite materials for lighter and stronger vessels, the mixing of smart sensors for real-time monitoring, and advanced welding strategies for more desirable sturdiness. There’s additionally a developing emphasis on sustainable and power-efficient designs to reduce environmental impact.

How do regulations and standards impact the design and operation of pressure vessels?

Regulations and requirements are essential in ensuring the safety and efficiency of pressure vessels. They dictate design specifications, material choices, creation techniques, and inspection protocols. Compliance with requirements like ASME (American Society of Mechanical Engineers) is mandatory in lots of regions. These standards are usually updated to reflect technological improvements and protection research, making compliance a dynamic and ongoing procedure.

Table of Contents

ToggleRelated Blog Post

- Who invented pressure vessels?

- What is the pressure theory in physics?

- What is the thick pressure vessel theory?

- What is the ideal pressure vessel shape?

- How does ASME define a pressure vessel?

- What is one criterion for design of a safe pressure vessel?

- What are the material selection for pressure vessel design?

- What is the minimum design pressure of a pressure vessel?

- Which theory of failure is used while designing a pressure vessel Why?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.