Unveiling the Three Main Types of Pressure Tanks

Table of Contents

ToggleWhy Pressure Tank Selection Matters for Your Operation

Pressure tanks are specialized vessels designed to store fluids or gases under pressure while maintaining system stability and safety. Unlike simple storage containers, these engineered systems handle internal pressures and serve critical functions across industries—from oil and gas operations to water treatment facilities.

Key benefits of proper pressure tank selection:

- Improved system efficiency and performance

- Reduced maintenance costs and downtime

- Enhanced safety and regulatory compliance

- Better return on investment

Industries That Depend on Pressure Tanks

Pressure tanks are essential in:

- Oil & Gas: Storage and transport of petroleum products

- Water Treatment: Municipal and industrial water systems

- Power Generation: Steam and cooling systems

- Manufacturing: Process control and automation

- Renewable Energy: Biogas and solar thermal systems

Why Choosing the Right Type of Pressure Tank Matters

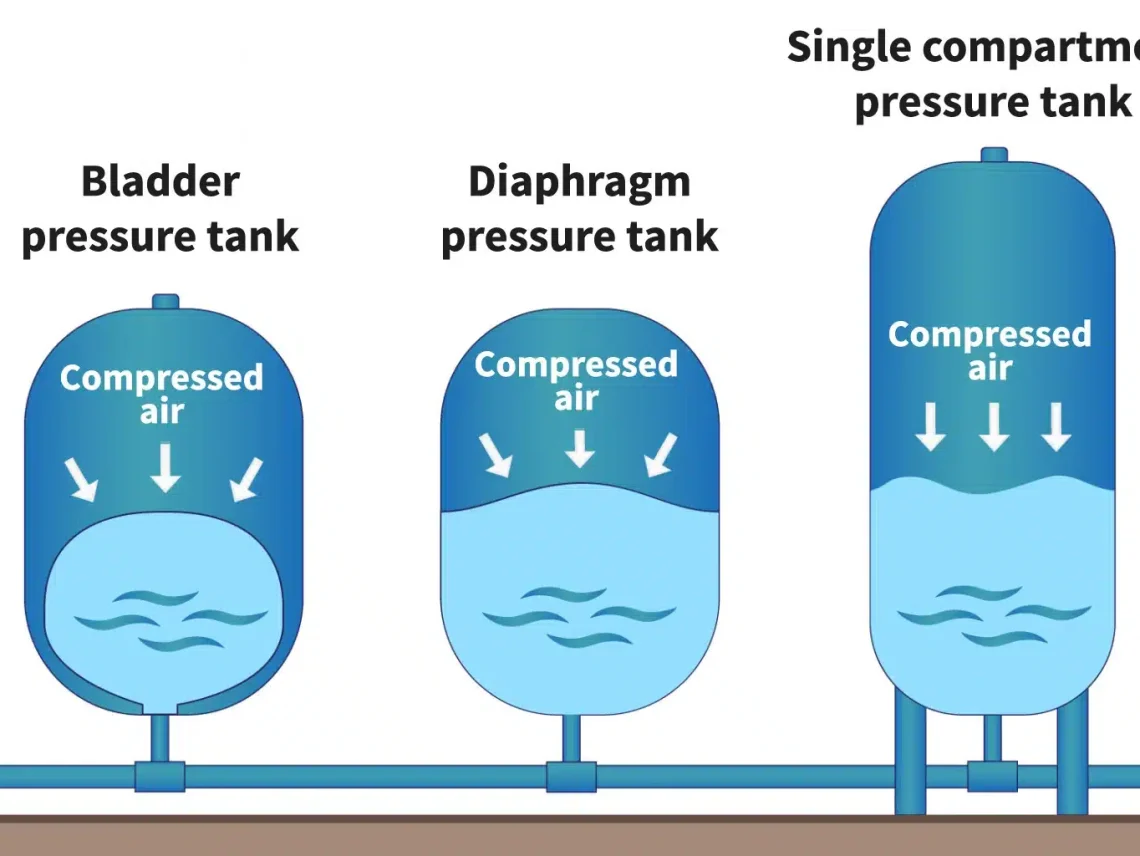

Selecting the appropriate pressure tank is not just a matter of preference—it’s also a strategic decision that impacts efficiency, safety, and cost-effectiveness. With this in mind, various types of pressure tanks used in industry each serve a unique purpose. For example, air-over-water tanks offer simplicity and reliability, diaphragm tanks bring flexibility and maintenance ease, while bladder pressure tanks provide superior separation of air and water. At Red River, not only do we manufacture pressure tanks, but we also partner with you to determine the best fit for your needs, ensuring that you have the right type of pressure vessel for your specific application.

How Pressure Tanks Work: The Fundamentals

Basic Operating Principles

Pressure tanks maintain consistent system pressure through air-water separation technology. When water enters the tank, it compresses the air space, creating pressure that pushes water through your system when needed. This eliminates the need for pumps to run continuously.

The pressure cycle works like this:

- Pump fills tank, compressing air

- Compressed air maintains system pressure

- Pressure forces water out when taps/systems demand flow

- Pump restarts when pressure drops to preset level

Essential Safety Features

Modern pressure tanks include:

- Pressure relief valves – prevent over-pressurization

- Pressure gauges – monitor system status

- Air release valves – remove excess air

- Corrosion-resistant coatings – extend tank life

Safety Features and Mechanisms in Pressure Tanks

Safety is paramount in pressure tank design. To achieve this, our tanks feature built-in safety mechanisms, including pressure relief valves, which prevent over-pressurization. Moreover, they are constructed with robust structural materials that withstand the stresses of pressurized storage. Ultimately, these features ensure that even in high-demand situations, the tanks operate within safe limits, providing peace of mind and compliance with industry safety standards.

Type 1: Air-Over-Water Pressure Tanks - The Traditional Choice

How Air-Over-Water Tanks Work

Air-over-water tanks use direct contact between air and water to maintain pressure. Air sits above the water in the tank, getting compressed as water levels rise.

Best Applications for Air-Over-Water Tanks

Ideal for:

- Large-scale municipal water systems

- Industrial applications with high volume needs

- Systems where cost is the primary concern

- Applications with easy maintenance access

Air-Over-Water Tank Pros and Cons

Advantages | Disadvantages |

Lowest upfront cost | Requires regular air addition |

Simple design, easy repairs | Water can become air-logged |

High capacity available | Takes up more space |

Proven reliability | Less energy efficient |

Type 2: Diaphragm Pressure Tanks - The Balanced Solution

How Diaphragm Tanks Provide Superior Control

Diaphragm tanks use a flexible rubber membrane to separate air and water completely. This prevents air absorption into water and eliminates the need for frequent air additions.

Installation and Maintenance Benefits

Installation advantages:

- Pre-charged with air – ready to install

- Compact design fits in smaller spaces

- Multiple mounting options available

Maintenance benefits:

- No regular air addition needed

- Diaphragm replacement every 5-7 years

- Easy pressure adjustment

When to Choose Diaphragm Tanks

Best for:

- Residential well water systems

- Small to medium commercial applications

- Systems requiring consistent pressure

- Locations with limited maintenance access

Type 3: Bladder Pressure Tanks - Maximum Efficiency

Why Bladder Tanks Are Growing in Popularity

Bladder tanks use a replaceable rubber bladder inside a steel tank to completely separate air and water. This design offers the highest efficiency and longest service life.

Bladder Tank Advantages

Key benefits:

- 95% usable water volume (vs. 30% for air-over-water)

- Longest lifespan – 15-20 years typical

- Best pressure consistency

- Easiest maintenance – bladder replacement only

Bladder vs. Diaphragm: Which Is Better?

Feature | Bladder | Diaphragm |

Water capacity | 95% usable | 75% usable |

Maintenance | Bladder replacement | Diaphragm replacement |

Cost | Higher upfront | Lower upfront |

Efficiency | Highest | High |

Best for | High-demand systems | Standard applications |

Pressure Tank Comparison: Making the Right Choice

Side-by-Side Comparison Table

Tank Type | Best For | Cost | Maintenance | Efficiency | Lifespan |

Air-Over-Water | Large municipal systems | Lowest | High | Fair | 15-20 years |

Diaphragm | Residential/small commercial | Medium | Low | Good | 10-15 years |

Bladder | High-demand applications | Highest | Lowest | Excellent | 15-20 years |

Selection Criteria Checklist

Consider these factors:

- System demand: How much water/pressure do you need?

- Space constraints: What size tank fits your location?

- Budget: What’s your upfront vs. operating cost preference?

- Maintenance access: How easy is it to service the tank?

- Efficiency requirements: How important is energy savings?

Sizing Your Pressure Tank: A Practical Guide

Tank Size Calculation Formula

For residential systems:

Tank Size = (Flow Rate × 4) ÷ (% Usable Capacity)

Example: 10 GPM system needs:

- Air-over-water: (10 × 4) ÷ 0.30 = 133 gallons

- Diaphragm: (10 × 4) ÷ 0.75 = 53 gallons

- Bladder: (10 × 4) ÷ 0.95 = 42 gallons

Common Sizing Mistakes to Avoid

- Undersizing: Causes frequent pump cycling, reducing pump life

- Oversizing: Wastes money and space without benefits

- Ignoring elevation: Higher elevations need larger tanks

- Forgetting peak demand: Size for maximum, not average flow

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. How long do pressure tanks last?

- Air-over-water: 15-20 years with proper maintenance

- Diaphragm: 10-15 years (diaphragm replacement needed)

- Bladder: 15-20 years (bladder replacement every 10-15 years)

2. Can I install a pressure tank myself?

While possible for smaller residential tanks, professional installation is recommended for:

- Tanks over 100 gallons

- Commercial applications

- Complex system integration

- Warranty compliance

3. What size pressure tank do I need?

Tank size depends on:

- System flow rate (GPM)

- Acceptable pump cycle frequency

- Available space

- Tank type efficiency

Use our sizing calculator above or consult with a professional for complex systems.

4. How much does pressure tank replacement cost?

Typical costs include:

- Residential tank (20-80 gallons): $400-$1,200 installed

- Commercial tank (100-500 gallons): $1,500-$5,000 installed

- Large municipal tanks: $10,000-$50,000+ installed

Table of Contents

ToggleRelated Blog Post

- Is water tank a pressure vessel?

- Is a water heater a pressure vessel?

- What is the purpose of a pressure vessel?

- Should a pressure vessel have water in it?

- At what pressure does a tank become a pressure vessel?

- Is a compressed air tank considered a pressure vessel?

- Is air receiver tank a pressure vessel?

- What are the three types of pressure tanks?

- What is a pressure vessel for domestic water?

- Why would I need a pressure tank?

- Is a blowdown tank a pressure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.