Why Training is Essential in Welding and Fabrication

Table of Contents

ToggleTraining is Essential in Welding and Fabrication

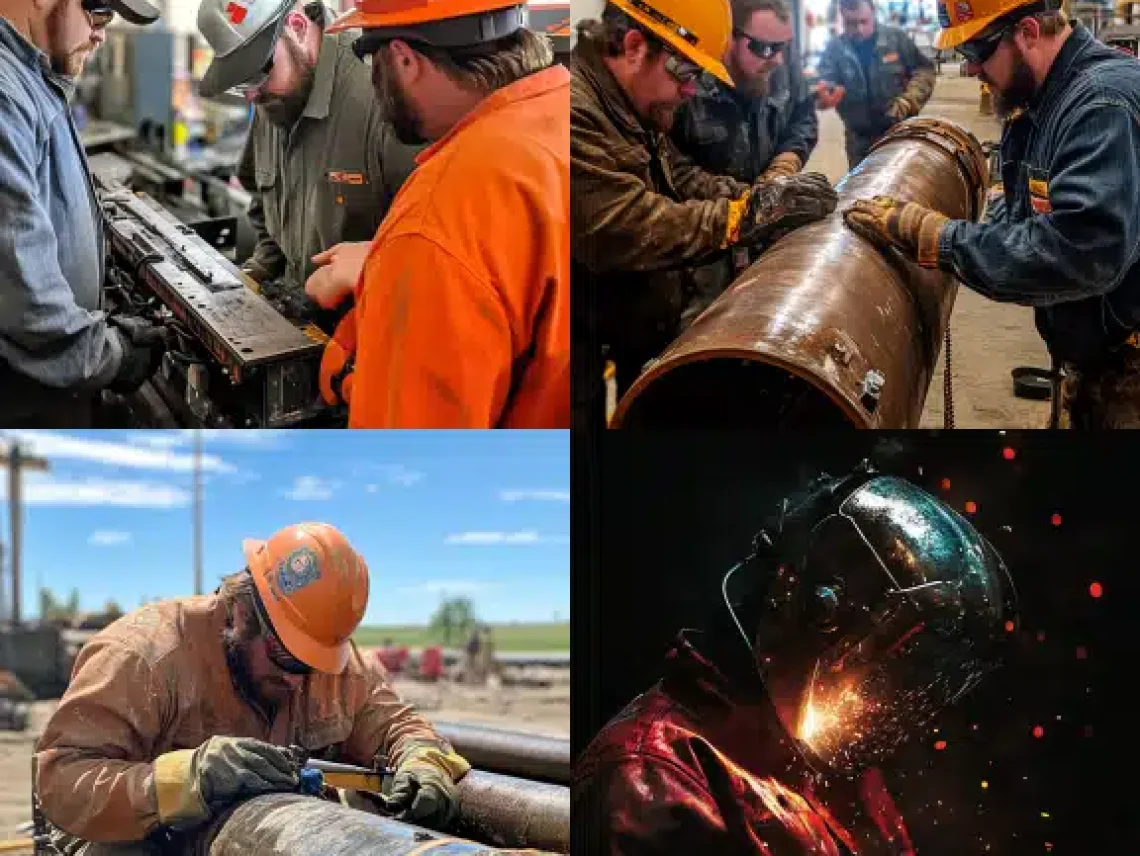

At Red River, investing in the right training starts with overcoming welding and fabrication challenges. Therefore, the importance of training in solving welding and fabrication issues can’t be overstated—it’s the backbone of delivering the high-quality results our clients expect. By doing so, we ensure that every project we take on meets the highest standards of precision, safety, and efficiency. As a result, when you partner with Red River, you can trust that our skilled workforce has the tools and expertise to tackle any challenge.

Addressing Common Welding and Fabrication Challenges

Welding and fabrication projects often have their share of difficulties—dealing with defects, material inconsistencies, or unexpected delays. For instance, identifying and addressing these issues early is crucial to keeping a project on track. Additionally, training helps our team avoid these obstacles, minimizing costly mistakes and rework. Furthermore, from enhancing welding quality to ensuring compliance with strict industry standards, our trained team understands the nuances of each challenge. Consequently, we are able to deliver results that last.

The Benefits of Continuous Training for Welders and Fabricators

Training isn’t a one-time event; it’s an ongoing commitment that drives our success at Red River. In fact, continuous training equips our welders with the latest techniques, technologies, and safety protocols, ensuring we stay ahead of industry trends. Not only that, but this also improves precision and reduces errors, boosting overall efficiency. Moreover, skilled workers are more adept at problem-solving, which leads to quicker turnarounds and less downtime. Ultimately, your projects are completed on time, within budget, and without compromising quality.

How Red River Invests in Skilled Labor

At Red River, we don’t just talk about the value of skilled labor—we invest in it. We offer specialized welding training programs that ensure our team is always improving. We can enhance our work’s quality and efficiency by focusing on everything from advanced welding techniques to safety protocols. Our commitment to professional training translates directly to better project outcomes for you. When you work with Red River, you’re partnering with a team with the expertise and training to get the job done right the first time.

Key Areas of Training to Overcome Welding and Fabrication Obstacles

At Red River, we recognize that proper training is key to overcoming common obstacles in welding and fabrication. Our training programs focus on safety, advanced techniques, and quality control.

Welding Safety and Compliance

Safety is the foundation of every successful welding and fabrication project. Our team undergoes rigorous safety training to ensure compliance with industry standards and certifications, such as ASME. This protects our workers and guarantees that your project meets all necessary regulations, minimizing risk and potential downtime.

Advanced Techniques in Welding and Fabrication

Our specialized training keeps our team on the cutting edge as welding and fabrication technologies evolve. From robotic welding to precision fabrication methods, these advanced skills allow us to handle even the most complex projects accurately and efficiently. This ensures that our clients receive superior results, no matter how challenging the project.

Quality Control and Inspection Training

Maintaining high-quality standards is essential to our success. Our workers are trained to identify and correct defects early through dedicated quality control and inspection training, minimizing waste and ensuring flawless execution. This results in consistent, reliable products that meet or exceed expectations.

The Impact of Proper Training on Project Efficiency and Cost Reduction

At Red River, we know that investing in proper training for our welders directly enhances project efficiency and reduces costs. Skilled workers with the right knowledge make all the difference in delivering successful projects on time and within budget.

How Trained Welders Save Time and Resources

When welders receive comprehensive training, they significantly reduce errors and minimize the need for costly rework. This precision not only saves valuable resources but also ensures that timelines are met without sacrificing quality. Trained welders work with improved speed, allowing for efficient project completion while maintaining the high standards that Red River is known for.

Boosting Customer Satisfaction through Skilled Fabrication

Skilled fabrication benefits the project and boosts customer satisfaction. When clients see their projects completed excellently and precisely, it builds trust and strengthens relationships. High-quality work reflects positively on your business, leading to positive word-of-mouth, repeat business, and long-term partnerships. At Red River, we pride ourselves on maintaining these high standards, ensuring that every project we deliver exceeds expectations.

Need a reliable partner?

Frequently Asked Questions (FAQ)

Why is ongoing training important for welders and fabricators?

Ongoing training is crucial because the welding and fabrication industry continuously evolves with new technologies, materials, and methods. Regular training keeps workers up-to-date on the latest techniques, improving efficiency and safety. Additionally, continuous learning helps welders develop problem-solving skills to handle unexpected challenges more effectively. This leads to higher-quality work, fewer errors, and less rework, saving time and reducing project costs.

What are some of the most common challenges in welding and fabrication that training addresses?

Training helps address several common challenges in welding and fabrication, including material defects, welding inconsistencies, and compliance with industry standards. Welders who are properly trained can identify potential issues early, reducing the likelihood of rework and project delays. Training also equips workers to adapt to different project specifications, whether working with carbon steel, stainless steel, or other materials. Additionally, proper safety training ensures compliance with industry regulations, protects workers, and reduces risks on the job.

How does training in advanced welding techniques benefit complex projects?

Training in advanced welding techniques, such as robotic welding and precision fabrication, is particularly beneficial for complex projects that demand high precision and consistency. These modern methods allow welders to achieve more accurate results in less time, improving overall project efficiency. In addition, advanced techniques are often required for working with new materials or highly specialized applications, and trained welders can confidently navigate these complexities, ensuring that the project meets the specifications without costly errors or delays.

How does quality control training improve the final product?

Quality control training teaches workers to maintain high standards throughout fabrication. This includes learning to perform inspections, detect defects early, and ensure that each part of the project meets industry and safety standards. By catching potential problems before they escalate, quality control training helps reduce waste and rework, leading to a more reliable and durable final product. It also ensures the project complies with all required certifications, enhancing the pressure vessels’ safety and longevity.

What certifications are typically required in the welding and fabrication industry, and how does training help with compliance?

In the welding and fabrication industry, certifications like those provided by the American Society of Mechanical Engineers (ASME) are often required to ensure compliance with safety and quality standards. Training is essential for helping welders understand and meet these certification requirements. For example, ASME-certified welders must be proficient in specific welding processes and demonstrate their ability to produce work that meets strict quality criteria. Through dedicated training programs, welders and fabricators can gain the skills and knowledge necessary to pass these certification exams, ensuring their work is up to industry standards.

Table of Contents

ToggleRelated Blog Post

- What materials pose the biggest challenges in welding fabrication?

- How do different welding techniques solve common fabrication issues?

- What are the best practices for reducing welding and fabrication costs?

- What are the challenges of welding unfamiliar materials in custom fabrication?

- How does environmental impact affect welding and fabrication challenges?

- What are the common welding challenges in high-pressure vessel fabrication?

- How does automation impact the challenges faced in welding and fabrication?

- How can welders overcome distortion issues in large-scale fabrication projects?

- What are the top safety concerns in welding and fabrication, and how can they be addressed?

- What are the cost implications of overcoming challenges in custom welding and fabrication?

- What are the common welding defects, and how do they affect fabrication quality?

- What are the latest technologies addressing challenges in welding and fabrication?

- What are the industry standards for overcoming welding challenges in fabrication?

- How does metallurgy influence the challenges faced in welding and fabrication?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.