Why Choosing the Right Fuel Water Separator Matters

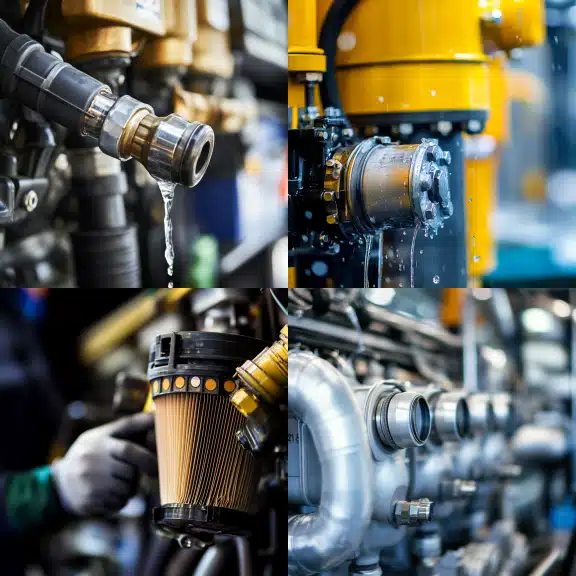

Fuel water separators are critical in preventing water contamination in diesel and industrial fuel systems. Without them, water in fuel can cause corrosion, injector damage, and engine failure. Choosing the right separator depends on your fuel type, system specs, and operating environment. Regular maintenance and correct sizing enhance efficiency and equipment lifespan. Red River offers […]

Do Diesel Fuel Filters Stop Water? Everything You Need to Know

Water in diesel fuel can lead to severe engine damage. Diesel fuel filters are your first line of defense, especially when paired with a water separator. Regular maintenance and smart fuel handling practices help prevent water-related issues and keep your engine running efficiently. Understanding the Importance of Diesel Fuel Filters in Preventing Water Contamination Water […]

Why It Is Important to Drain Water from Your Fuel Manager?

Water in your fuel manager is more than a nuisance—it’s a serious risk to your diesel engine. If left unchecked, it leads to rust, injector damage, and system failure. Draining your fuel manager regularly—every 3 to 6 months—is critical. Follow a safe, step-by-step process, and choose a properly sized, high-quality fuel manager for your operating […]

Understanding Water Separation in Industrial Applications

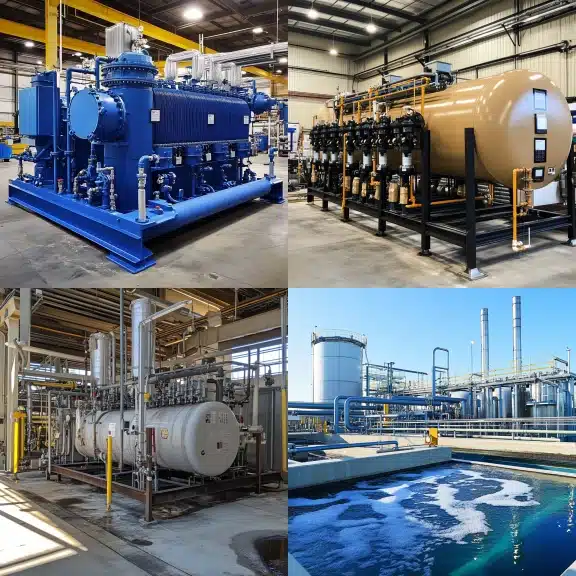

Efficient water separation in industrial applications protects equipment, reduces downtime, and supports compliance with environmental standards. Methods like gravity separation, coalescers, and filtration are vital to maintaining clean process streams. Poor water removal leads to corrosion, system failure, and regulatory issues. At Red River, we tailor water separation solutions to each operation, ensuring maximum efficiency […]