Industrial High-Pressure Vessel Challenges in Modern Processing

Industrial high-pressure vessels face extreme mechanical stresses that demand precise design, robust material selection, and stringent welding, inspection, and testing to prevent catastrophic failures. Adhering to industry codes and rigorous safety protocols ensures operational reliability, long-term durability, and protection against environmental and human hazards. Understanding Industrial High-Pressure Vessel Challenges and Risks Industrial high-pressure vessel challenges […]

Standard vs. Custom Vessels: Choosing the Right Solution for OEM Applications

Standard OEM pressure vessels are cost-effective, fast to deliver, and ideal for predictable, low-risk applications with common operating requirements. Custom OEM pressure vessels are better suited for complex, high-risk, or highly regulated projects where precise design, specialized materials, and strict compliance are critical for long-term performance and safety. Standard vs. Custom Vessels: When to Choose […]

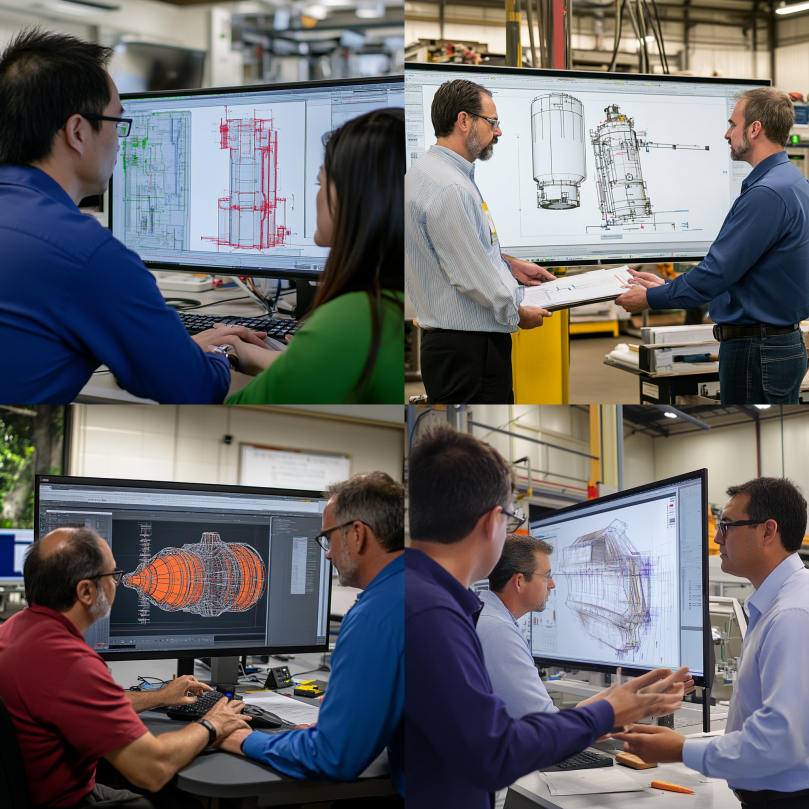

The CAD, FEA Engineering Role in OEM Pressure Vessel Design

The CAD, FEA engineering role in OEM pressure vessel is foundational to modern manufacturing. These digital tools bridge the gap between concept and fabrication by enabling engineers to design, simulate, and validate vessels before a single piece of metal is cut. Whether optimizing wall thickness, predicting stress behavior, or ensuring compliance with ASME codes, CAD […]

OEM Vessel Fabrication Innovations: Enhancing Pressure Vessel Strength and Precision

OEM vessel fabrication innovations like robotic welding, CNC machining, additive manufacturing, advanced NDT, and digital twins are transforming pressure vessel manufacturing by improving precision, reducing errors, speeding production, and lowering costs across industries with strict performance and safety requirements. As these technologies enable more customized, scalable, and sustainable fabrication, manufacturers must adopt them to stay […]

Achieving OEM Build Precision: Meeting Tight Tolerances in Pressure Vessel Builds

Achieving OEM Build Precision in Pressure Vessel Manufacturing Achieving OEM build precision is paramount in pressure vessel manufacturing, where meeting tight tolerances is not just a requirement but a critical factor influencing safety, operational performance, and regulatory compliance. In this highly specialized field, precision ensures that every pressure vessel integrates seamlessly into broader system architectures, […]

Modular vs Integrated Design in OEM Pressure Vessels

Modular vs Integrated Design: Choosing the Best Pressure Vessel Strategy Modular vs. Integrated Design is a key consideration in OEM pressure vessel engineering, sparking ongoing debate among manufacturers, system designers, and engineers aiming to optimize performance. The choice between Modular vs Integrated Design plays a crucial role in determining how well a pressure vessel system […]

Optimize Flow Using Vessels in U.S. Factories

Improving Process Flow in Factories Using Vertical Pressure Vessels Improving process flow in factories using vertical pressure vessels has rapidly become a strategic priority for modern American manufacturing facilities. As businesses seek innovative solutions to maximize production efficiency and space utilization, more operations are turning to vertical pressure vessels to optimize flow using vessels designed […]