3-Phase Separation Technology

Table of Contents

ToggleIntroduction to 3-Phase Separator Efficiency

What Is a 3-Phase Separator?

A 3-phase separator is an indispensable tool in the oil and gas, power generation, biogas, and water treatment industries. More specifically, it is designed to efficiently separate gas, oil, and water from a mixed stream, ensuring optimal purity and performance in processing operations. At Red River LLC, we understand that the nuances of these systems can be complex, which is why we offer customized solutions that precisely meet the needs of your operation.

Core Principles of 3-Phase Separator Efficiency

Basics of Separation: Oil, Water, and Gas

Understanding the fundamentals of oil, water, and gas separation is not only essential but also crucial for maintaining efficient process operations. To achieve this, our team leverages its expertise to ensure that your 3-phase separator is designed for maximum separation efficiency. This process is carefully tailored to the specific characteristics of your feed stream, allowing for optimal results.

How 3-Phase Separators Work

At the heart of every 3-phase separator is a carefully engineered process that balances physics and chemistry in order to achieve optimal separation. To accomplish this, we employ advanced welding and fabrication techniques, which help maintain the integrity and performance of each unit. Ultimately, this reflects our dedication to quality and compliance.

Innovations in 3-Phase Separation Processes

Innovation is what drives us at Red River. Because of this, we remain at the forefront of integrating automation, material science advances, and custom engineering solutions. As a result, we enhance the functionality and efficiency of 3-phase separators. Our approach ensures that you benefit from the latest advancements in separation technology.

Types of 3-Phase Separator Efficiency

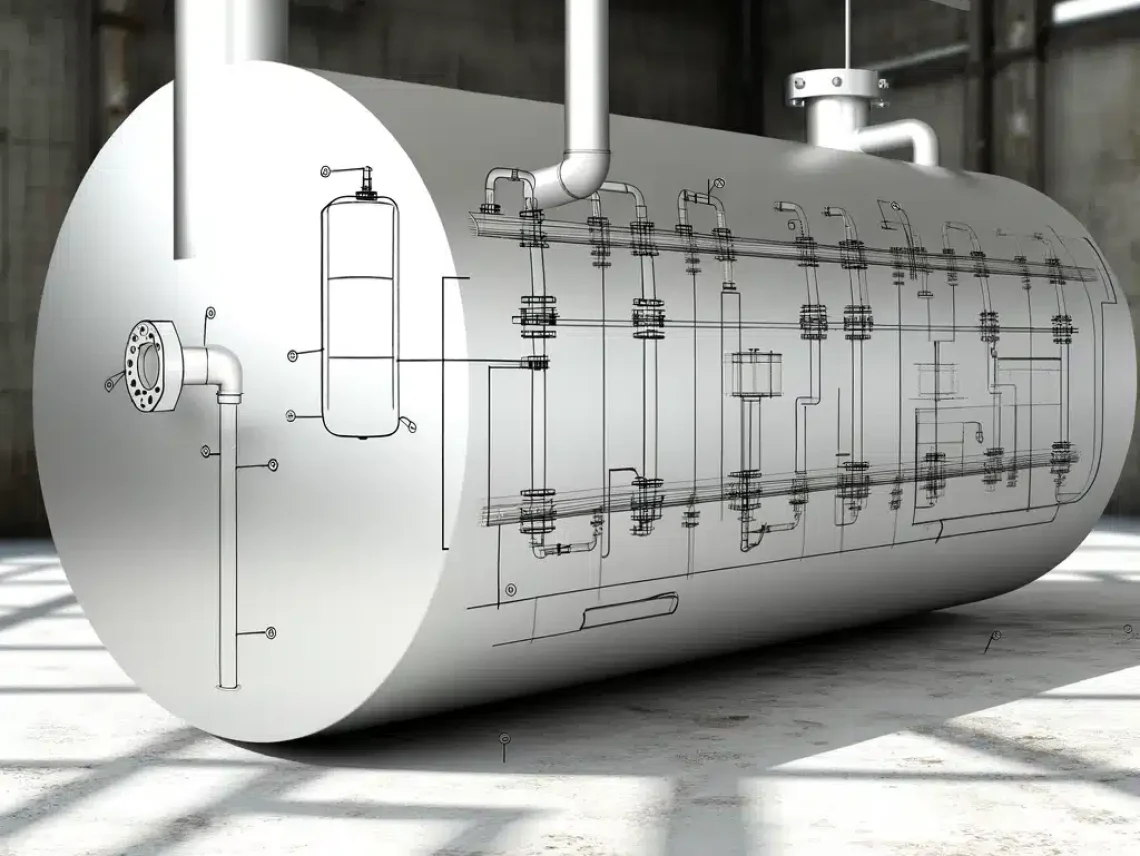

Horizontal 3-Phase Separators

Designed for high efficiency and versatility, our horizontal 3-phase separators excel in applications that require significant throughput and flexibility. More specifically, they are ideal for handling varying feed conditions, ensuring seamless operation across different industrial settings.

Vertical 3-Phase Separators

When space is at a premium, our vertical 3-phase separators provide a highly effective compact solution without sacrificing performance. Because of this, they are particularly well-suited for offshore platforms and confined industrial spaces, where every inch of space matters.

Spherical 3-Phase Separators

For high-pressure applications, spherical separators offer a unique and efficient solution. By combining robustness with efficiency, they provide a compact design that is especially tailored for challenging environments, ensuring reliable performance under demanding conditions.

Need a reliable partner?

Frequently Asked Questions About 3-Phase Separator Efficiency

How do environmental regulations impact the design and operation of 3-phase separators?

Environmental regulations play a crucial role in designing and operating 3-phase separators, especially in industries like oil and gas, power generation, and water treatment. These regulations dictate the maximum allowable emissions and discharge levels, influencing separator size, materials, and technology choices. To comply with standards, engineers design separators to minimize VOC (Volatile Organic Compound) emissions and ensure that discharged water meets or exceeds cleanliness standards.

Can 3-phase separators be used in mobile or temporary installations, and what are the challenges?

Yes, operators can configure 3-phase separators for mobile or temporary installations, such as well testing or early production facilities. However, these setups present challenges, including maintaining stability and proper level control under varying conditions. Quick setup and teardown must happen without compromising operational efficiency or safety. To address these concerns, mobile separators often incorporate modular designs and flexible connection systems, enabling rapid deployment and reconfiguration based on site requirements.

How do the specific gravity differences between oil, water, and gas affect separator design?

The differences in specific gravity between oil, water, and gas significantly impact separator design, influencing how efficiently the separator separates these phases. Since gas has the lowest specific gravity, it naturally rises to the top, while oil (with a medium-specific gravity) settles in the middle, and water (with the highest specific gravity) collects at the bottom. To optimize separation efficiency, designers must account for variations in the specific gravity of processed fluids, which can change significantly.

How does temperature and pressure affect the operation of a 3-phase separator?

Temperature and pressure significantly impact the operation and efficiency of 3-phase separators. High temperatures can reduce the viscosity of oil, improving separation but may also increase the volatility of certain compounds, complicating gas separation. Pressure, on the other hand, affects the density and phase behavior of the fluids. Separators must be designed to operate efficiently across the expected temperature and pressure range of the application, incorporating controls and safety systems to manage fluctuations.

What are the latest advancements in 3-phase separation technology?

The latest advancements in 3-phase separation technology focus on enhancing efficiency, reducing environmental impact, and improving automation. Innovations include compact flotation units that use small bubbles to improve the separation of oil from water, multi-phase cyclonic separators that can handle high gas-to-liquid ratios, and smart separation solutions that incorporate sensors and IoT technology for real-time monitoring and optimization.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.