The definition of ASME refers to the American Society of Mechanical Engineers and its globally recognized standards, especially the ASME Boiler and Pressure Vessel Code (BPVC). These codes govern the design, fabrication, and certification of pressure vessels across industries. Red River LLC strictly adheres to ASME standards to deliver safe, compliant, and reliable pressure vessels for energy, pharma, aerospace, and beyond.

The definition of ASME the American Society of Mechanical Engineers centers on its role as a global leader in engineering codes and safety standards. When it comes to pressure vessels, the ASME definition sets the benchmark for design, construction, and compliance. These standards are not just technical suggestions; they’re the backbone of Red River’s quality assurance. By adhering to ASME’s pressure vessel definition and criteria, we ensure that every vessel we manufacture is durable, safe, and industry-compliant. Visit the official ASME website to learn more about its mission and scope.

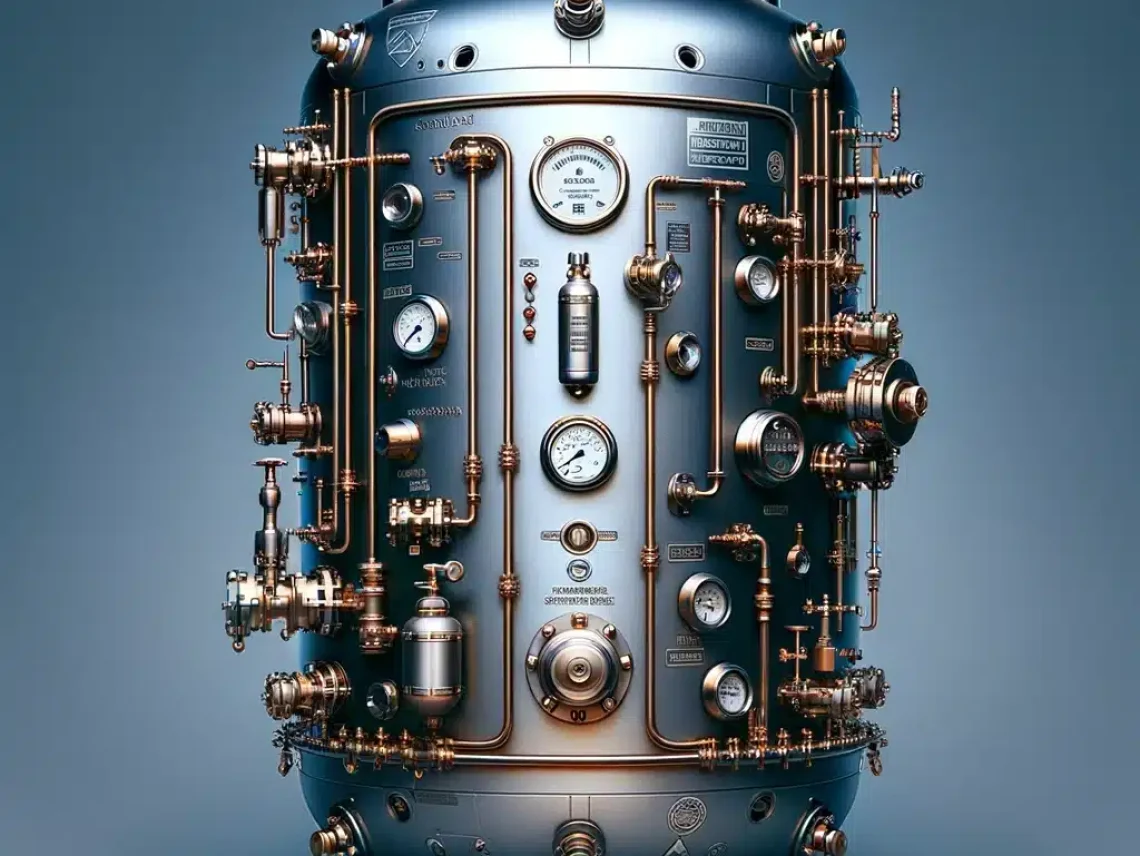

Pressure vessels are greater than just bins; they are vital additives in a huge variety of industries, such as oil and gasoline, power technology, and biogas. These vessels hold gases or drinks at a pressure extensively distinctive from the ambient pressure, making their integrity and reliability non-negotiable. At Red River, we understand the importance of those vessels for your operations. Whether it’s for processing, garage, or shipping, we make certain that every pressure vessel we manufacture is a testomony to our unwavering dedication to exceptional protection.

ASME’s position in placing pressure vessel standards is set more than simply defining what a pressure vessel is. It’s approximately establishing a framework for safety, efficiency, and innovation. These standards manual us in deciding on substances, designing for specific pressures and temperatures, and making sure each vessel’s sturdiness and performance. At Red River, we don’t simply meet these requirements; we intend to exceed them. Our team of professional experts is nicely versed in decoding and imposing ASME recommendations, ensuring that every pressure vessel we produce is not only the best compliant but additionally a step in advance in terms of first-class and reliability.

ASME defines pressure vessels via particular criteria, focusing on their ability to keep gases or liquids at excessive pressures. This classification is essential in guiding producers like Red River in growing safe, efficient, and reliable vessels.

The term ASME typically refers to the American Society of Mechanical Engineers, which sets engineering codes and safety standards. When people search for the definition of ASME, they’re often referring to ASME’s Boiler and Pressure Vessel Code (BPVC), particularly Section VIII. This code defines pressure vessels as containers designed to hold gases or liquids at a pressure significantly different from ambient pressure, and outlines the rules for their safe design and construction.

ASME requirements dictate the choice of materials and layout parameters, making sure every vessel’s integrity under numerous operational situations. Red River LLC meticulously adheres to these pointers, selecting the highest quality substances for sturdiness and performance. Learn more about how we select the right pressure vessel materials for safety and efficiency.

Temperature and pressure are pivotal in ASME’s definition of pressure vessels. These factors decide the vessel’s design and operational limits, ensuring safety in diverse business applications. A precise understanding of these variables helps engineers determine the correct material thickness and structural reinforcements.

Section VIII of the ASME code is the cornerstone of pressure vessel layout, outlining the standards for creation and inspection. Red River LLC’s knowledge of this location guarantees compliance and excellence. We build each vessel to exceed minimum design thresholds, providing long-term durability in the harshest environments. For a deeper look, visit our guide to the ASME code for pressure vessels. You can find the full code listing on ASME’s Codes & Standards Collection

Safety is paramount in ASME’s layout criteria. Red River LLC incorporates these safety functions, ensuring every vessel meets rigorous protection standards. Features like pressure relief valves, corrosion allowances, and non-destructive testing are standard in our builds.

ASME units complete necessities for pressure vessel fabrication, protecting everything from welding to checking out. Red River LLC’s fabrication procedure aligns with those necessities, ensuring pinnacle-notch first-class. We also conduct regular audits and training to ensure every technician operates to code-compliant standards.

Achieving ASME certification entails an in-depth process of design assessment, cloth selection, and rigorous checking out. Red River LLC navigates those steps with precision, ensuring compliance and best. Our internal quality control team manages this process end-to-end to eliminate risks and delays. Explore how we deliver fully ASME-certified pressure vessels that meet the strictest code expectations.

For producers, ASME certification is a mark of quality and reliability. Red River LLC values this certification as a testimony to our dedication to excellence. It also opens access to global markets where ASME compliance is mandatory.

ASME certification assures cease users of the safety and best of pressure vessels. Red River LLC’s adherence to these requirements instills self-assurance in our clients. It minimizes downtime, insurance risks, and costly failures in high-pressure operations.

Comparing ASME with European standards highlights distinct tactics for safety and design. Red River LLC understands those nuances, making sure of international compliance. This allows us to deliver vessels compliant with both ASME and PED requirements for global projects. See our full breakdown in the ASME standards and pressure vessel manufacturing guide. Kettering University provides a great overview in this Intro to ASME Codes & Standards PDF guide.

ASME standards are globally identified for his or her rigor and reliability, making them a benchmark in the industry. Red River LLC’s compliance with those requirements positions us as a leader within the worldwide marketplace. Clients across energy, pharma, and defense rely on ASME-certified vessels for mission-critical systems. Read more in The Pressure Vessel Industry: A Red River Overview.

Adapting ASME requirements to different international locations’ rules calls for information and versatility. Red River LLC’s enjoyment of global projects makes us adept at this version, ensuring global compliance and excellence. We customize vessel documentation to meet both local codes and ASME expectations.

ASME always updates its pressure vessel policies to reflect the latest protection and technological advancements. Red River LLC remains beforehand via integrating these modifications, making sure our merchandise meets cutting-edge enterprise requirements. We track Code Cases and Section VIII revisions to keep clients ahead of compliance changes.

Technological improvements significantly impact ASME requirements. Red River LLC embraces these improvements, from superior materials to cutting-edge production strategies, aligning our procedures with the present-day ASME requirements. This results in lighter, stronger, and more cost-efficient pressure vessel solutions.

ASME plays a pivotal position in shaping destiny developments in pressure vessel design. Red River LLC actively video displays units of these trends, preparing to incorporate futuristic designs and substances that meet evolving ASME requirements. We’re already exploring AI-based monitoring and smart sensor integration into ASME-compliant builds.

In the oil and fuel region, ASME-licensed pressure vessels are vital. Red River LLC has effectively introduced vessels that face up to severe situations, demonstrating our expertise in this annoying enterprise. Our custom builds have supported critical applications in refineries, midstream terminals, and offshore platforms.

For the pharmaceutical enterprise, ASME-licensed vessels ensure protection and purity. Red River LLC’s vessels meet those stringent requirements, proving essential in sensitive pharmaceutical procedures. We offer electropolished interiors and ASME BPE-compliant features when purity is paramount.

In aerospace and protection, ASME pressure vessels play a vital function. Red River LLC presents vessels that meet the high standards of durability and precision required in these sectors. Each unit undergoes additional testing protocols tailored to MIL-SPEC or aerospace-grade requirements.

ASME compliance is synonymous with protection. At Red River LLC, we prioritize this compliance, ensuring every vessel we manufacture adheres to the very best safety requirements. Our third-party verification processes give clients added assurance before installation.

ASME’s rigorous standards assist save you from industrial accidents. Red River LLC’s adherence to these requirements is a testimony to our commitment to protection and reliability. Well-defined inspection intervals and failure prevention protocols stem directly from ASME code adherence.

ASME standards additionally embody environmental considerations. Red River LLC designs and manufactures vessels that not only meet protection standards but also make contributions to environmental sustainability. Our designs minimize emissions and facilitate safe handling of volatile or hazardous materials.

At Red River LLC, our dedication to ASME compliance is unwavering. We make certain every vessel we produce meets or exceeds these rigorous standards. This ensures consistent quality across every unit, regardless of complexity or volume.

Our portfolio consists of several ASME-certified vessels, every exemplifying our expertise and adherence to fine and safety standards. Each case highlights our ability to solve unique engineering challenges under ASME code.

Choosing Red River LLC approach partnering with an agency that now not only is aware of ASME standards but additionally values protection, best, and innovation in each pressure vessel we manufacture. We bring a hands-on, consultative approach that ensures your vessel meets performance and compliance goals.

Understanding the definition of ASME is more than just knowing what the acronym stands for it’s about recognizing the critical role this organization plays in setting global safety and engineering standards. At Red River LLC, our commitment to ASME’s pressure vessel codes ensures that every product we manufacture is not only compliant but exceeds expectations in safety, performance, and reliability. Whether you’re in oil and gas, pharmaceuticals, or aerospace, ASME-certified vessels are essential to protecting your operations and your people.

At Red River LLC, we don’t just follow the ASME code we build to exceed it. Let’s talk about your project and how we can deliver safer, smarter solutions.

Contact Us Today to get a quote or speak with an expert.

When selecting materials for a pressure vessel, the important thing elements encompass the working temperature and pressure, the form of the substance being contained (whether or not it’s a fuel or liquid, and its corrosiveness), and the vessel’s meant environment. Materials ought to be selected primarily based on their ability to face up to these situations without degrading or failing. Additionally, compliance with industry standards like ASME is vital for ensuring safety and sturdiness.

Temperature and pressure are pivotal in determining the thickness, form, and cloth of a pressure vessel. High pressures necessitate stronger, stronger materials and often thicker partitions to save you from rupture. Similarly, excessive temperatures, both high and low, require substances that could face up to thermal enlargement or contraction without dropping integrity. The layout must account for those elements to make certain the vessel operates appropriately beneath its meant situations.

The number one distinction lies in the regulatory technique and particular technical necessities. ASME requirements, extensively utilized in North America, awareness closely on specific design formulas and unique fabric standards. European standards, such as the Pressure Equipment Directive (PED), tend to be more holistic, emphasizing general protection objectives and permitting greater flexibility in reaching those dreams. Both units of requirements ensure certain safety and reliability but vary in their methodologies and compliance requirements.

Yes, pressure vessels may be considerably custom-designed to meet precise industrial needs. This customization can include size, form, cloth type, internal lining, outside coatings, and the inclusion of additional capabilities like nozzles, flanges, or supports. Customization is crucial for industries with unique requirements, including prescription drugs, in which purity and cleanliness are vital, or in oil and gas, where vessels need to withstand harsh environments.

Prefabrication plays a significant role in improving the first-rate, performance, and price-effectiveness of pressure vessel production. By building components or complete vessels in a controlled manufacturing unit environment, manufacturers can reap better precision and first-rate manipulation. Prefabrication additionally reduces on-site production time and related dangers, main to usual value financial savings and advanced safety. It permits the combination of superior production strategies, inclusive of automatic welding and precision cutting, similarly enhancing the quality of the very last product.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.