Navigating Local Safety Regulations and Compliance in Wyoming

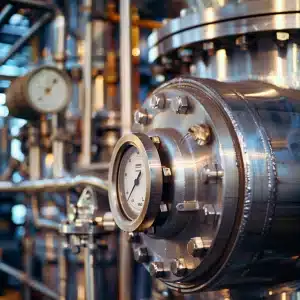

Introduction to Wyoming Safety Regulations for Pressure Vessels Wyoming’s safety policies are designed to defend workers, protect the surroundings, and safeguard the public. These laws cover a wide range of industries, from oil and fuel to the strength sector, embodying the spirit of American values. These values include resilience, self-reliance, and a strong commitment to community and safety. At Red River, we embrace these principles by ensuring that our pressure vessels are not only fully compliant with regulations but also contribute