Non-Destructive Testing (NDT) Methods for Pressure Vessel Safety

Non-Destructive Testing (NDT) ensures pressure vessel integrity without causing damage, using methods like visual, ultrasonic, radiographic, and magnetic particle testing. Regular NDT inspections by qualified technicians enhance safety, prevent failures, and maintain regulatory compliance. Non-Destructive Testing (NDT) Methods for Pressure Vessel Safety Pressure vessels are vital in industries like oil and gas, chemical processing, and […]

Understanding OSHA Pressure Vessel Safety Requirements for American Industry

OSHA pressure vessel regulations enforce workplace safety by requiring proper installation, regular inspections, maintenance, and employee training. Compliance reduces hazards, prevents violations, and ensures safe operation of pressurized equipment. OSHA Pressure Vessel Inspection and Testing Frequencies Pressure vessels are a cornerstone of industrial safety, used in industries ranging from petrochemical processing to food production and […]

Managing Martensite Formation in Quenched-and-Tempered Steels

Managing martensite formation in quenched-and-tempered steels requires precise control of composition, cooling rates, and tempering. Properly balancing these factors ensures the desired combination of hardness, strength, and toughness in steel components. Comprehensive Guide in Managing Martensite Formation Effectively managing martensite formation is critical for manufacturers working with quenched-and-tempered steels. Martensite, a hard and brittle microstructural […]

Designing for RNG System Pressurization

Proper pressurization in RNG systems is essential for safe, efficient, and reliable gas transport and utilization. Using high-quality pressure vessels, skid packages, and custom designs ensures optimal system performance and operational safety. The Importance of Pressurization in RNG Systems: Key Insights for Efficient Design Renewable Natural Gas (RNG) systems are at the forefront of the […]

Pressure Vessels vs. Water Tanks: What’s the Difference?

Pressure vessels are built to handle high-pressure fluids safely, while water tanks store fluids at low or atmospheric pressure. Choosing the right type ensures system efficiency, safety, and compliance with regulatory standards. Understanding Pressure Vessels vs. Water Tanks: A Critical Safety and Performance Decision When it comes to fluid storage and system efficiency, understanding the […]

Fiberglass vs Stainless Steel Pressure Vessels: Which is Right for You?

Fiberglass pressure vessels are lightweight, corrosion-resistant, and cost-effective for low-pressure, chemical environments, while stainless steel vessels excel in high-pressure, high-temperature, and sanitary applications. Choosing between fiberglass vs stainless steel pressure vessels depends on operational needs, budget, and regulatory requirements to ensure safety and long-term performance. The Critical Decision of Pressure Vessel Material Selection When it […]

Importance of Pressure Vessel Corrosion Protection Materials

Corrosion poses a major threat to water pressure vessels, but selecting materials like stainless steel, duplex stainless, FRP, or coated carbon steel ensures long-term protection, safety, and reliability. Proper pressure vessel corrosion protection reduces maintenance costs, extends equipment lifespan, and supports regulatory compliance across industrial and municipal applications. Selecting the Right Materials for Water Pressure […]

Understanding ASME Standards for Water Pressure Vessels

ASME standards for water pressure vessels ensure safe design, fabrication, testing, and inspection of pressurized water systems. Compliance reduces risk, extends equipment life, and meets regulatory and insurance requirements. The Imperative of ASME Standards for Pressure Vessels In industrial settings, safety and reliability are non-negotiable, especially when dealing with pressurized systems. One of the most […]

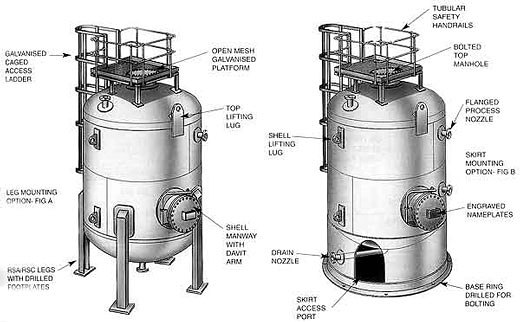

Skid-Mounted American Pressure Vessels: Benefits and Uses

Skid-mounted American pressure vessels are gaining popularity because they are factory-built, fully integrated systems that enable faster installation, lower costs, improved safety, and easy relocation. Their modular, space-efficient design makes them ideal for industries needing rapid deployment, scalability, and reliable performance across applications like oil & gas, chemicals, water, pharma, and food processing. Why Skid-Mounted […]

Carbon Recycling Vessel Applications in Clean Energy Systems

Carbon recycling vessel applications are critical to capturing, converting, and storing CO₂ across industries. Engineered for safety and performance, these pressure vessels support everything from post-combustion capture to direct air capture, enabling a scalable path to decarbonization and circular carbon use. How Carbon Recycling Vessel Applications Power Decarbonization Carbon recycling vessel applications are at the […]