Understanding Dehydrator Lifecycle Management

[ez-toc] Dehydrator lifecycle management focuses on designing, operating, maintaining, and disposing of dehydrators in ways that reduce energy use, emissions, and waste. By adopting sustainable materials, efficient technologies, and responsible disposal practices, businesses can significantly minimize environmental impact while improving performance and longevity. The Dehydrator Lifecycle Management At Red River, we recognize that environmental sustainability […]

Understanding Dehydrator Lifecycle Management

Dehydrator lifecycle management focuses on designing, operating, maintaining, and disposing of dehydrators in ways that reduce energy use, emissions, and waste. By adopting efficient technology, sustainable materials, and responsible disposal practices, businesses can extend equipment life while significantly lowering their environmental impact. The Dehydrator Lifecycle Management At Red River, we recognize that environmental sustainability is […]

Why Upgrading Aging Dehydrator Pressure Vessels is Crucial

[ez-toc] Aging dehydrator pressure vessels lose efficiency, increase safety risks, and drive up operational costs, making timely upgrades essential. Retrofitting extends equipment life, boosts performance, and delivers major long-term savings compared to full replacement. Upgrading Aging Dehydrator Pressure Vessels is Crucial As your dehydrator pressure vessels age, their efficiency and safety become increasingly critical. Upgrading […]

Why Upgrading Aging Dehydrator Pressure Vessels is Crucial

Aging dehydrator pressure vessels lose efficiency, increase safety risks, and drive up operational costs, making timely upgrades essential. Retrofitting extends equipment life, boosts performance, and delivers major long-term savings compared to full replacement. Upgrading Aging Dehydrator Pressure Vessels is Crucial As your dehydrator pressure vessels age, their efficiency and safety become increasingly critical. Upgrading older […]

Why Regular Inspection of Dehydrator Pressure Vessels is essential

[ez-toc] Regular inspection of dehydrator pressure vessels is essential for preventing corrosion, structural failures, and costly downtime. Proactive testing and maintenance significantly extend vessel lifespan and ensure safe, efficient industrial operations. Regular Inspection of Dehydrator Pressure Vessels Is Essential For dehydrator pressure vessels, regular inspections are critical to ensuring their safety and efficiency. Specifically, inspections […]

Why Regular Inspection of Dehydrator Pressure Vessels is essential

Regular inspection of dehydrator pressure vessels is essential for preventing corrosion, structural failures, and costly downtime. Dehydrator pressure vessel inspection combined with proactive testing and maintenance significantly extend vessel lifespan and ensure safe, efficient industrial operations. Regular Inspection of Dehydrator Pressure Vessels Is Essential For dehydrator pressure vessels, routine inspections are critical to maintaining safety, […]

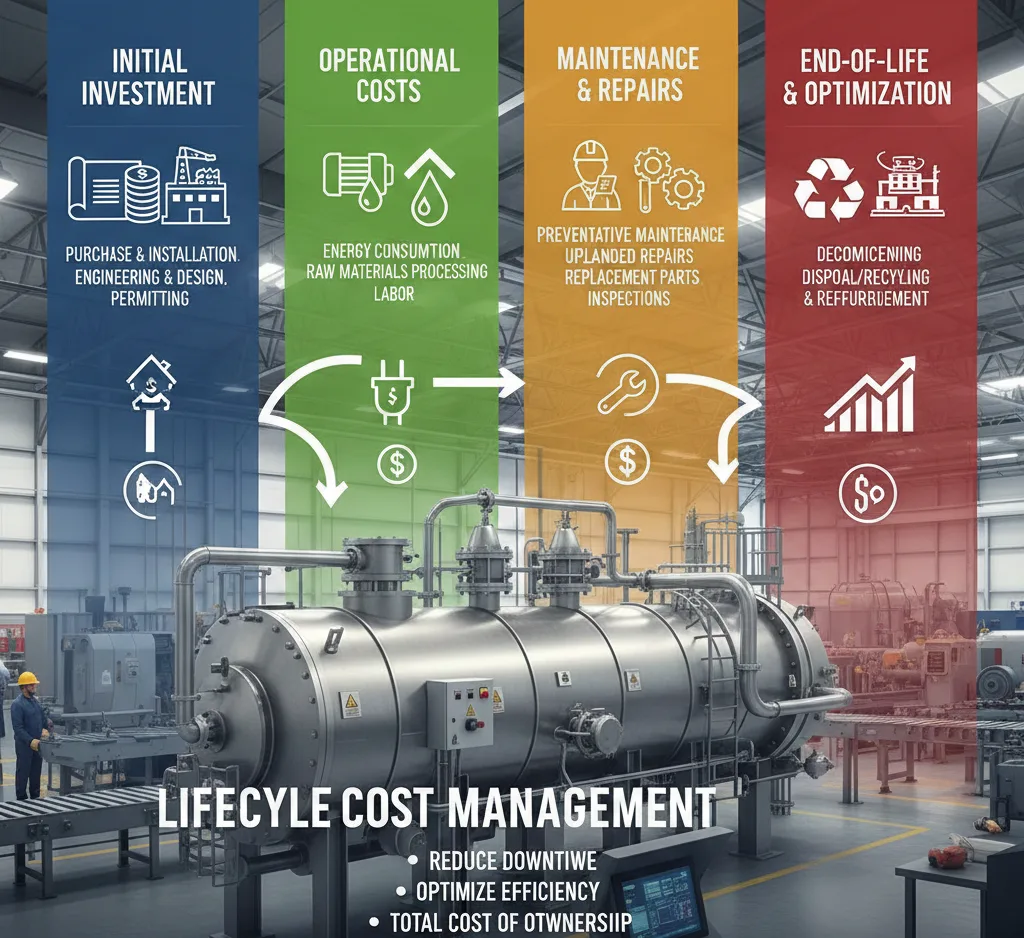

Understanding the Lifecycle Costs of Dehydrator Pressure Vessels

[ez-toc] Lifecycle costs for dehydrator pressure vessels go far beyond the upfront price, encompassing materials, energy use, maintenance, repairs, and downtime. Choosing high-quality materials and a reliable manufacturer significantly reduces long-term expenses while improving efficiency and durability. The Lifecycle Costs of Dehydrator Pressure Vessels When you invest in a dehydrator pressure vessel, it’s no longer […]

Understanding the Lifecycle Costs of Dehydrator Pressure Vessels

Lifecycle costs for dehydrator pressure vessels go far beyond the upfront price, encompassing materials, energy use, maintenance, repairs, and downtime. Choosing high-quality materials and a reliable manufacturer significantly reduces long-term expenses while improving efficiency and durability. The Lifecycle Costs of Dehydrator Pressure Vessels When you invest in a dehydrator pressure vessel, it’s no longer just […]

Heat Exchanger Selection in Dehydrator Systems

Heat Exchanger Selection in Dehydrator Systems directly affects energy use, drying consistency, and equipment life. The right exchanger keeps heat transfer stable, reduces wasted power, and protects downstream components from temperature swings. Selection also needs to account for pressure integrity, especially when exchangers tie into vessels and piping that operate under code limits. RedRiver LLC […]

Fluid Dynamics in Dehydrator Pressure Vessels

Fluid Dynamics in Dehydrator Pressure Vessels is the quiet driver behind dehydration performance, safety, and operating cost. When flow is balanced, water separates cleanly, pressure stays stable, and internals last longer. Poor flow creates carryover, hotspots, and unnecessary strain on the vessel. RedRiver LLC designs dehydrator pressure vessels with flow behavior in mind, helping operators […]