Separator Efficiency for Better Operations

[ez-toc] Factors Influencing Separator Performance Flow Rate and Viscosity Effects on Separation Efficiency The glide price and viscosity of the fluid being processed significantly impact the separator’s overall performance. For example, higher flow rates can increase turbulence in the separator, thereby affecting the efficiency of phase separation. Furthermore, the viscosity of the fluid can influence […]

Oil Separation Technology

[ez-toc] Types of Oil Separators API Separators: Design and Function Our API separators are the backbone of oil-water separation in many industrial applications. By utilizing the principles of gravity separation, these units are specifically designed to remove oils and solids from wastewater efficiently. Furthermore, at Red River, we believe in the power of innovation and […]

The Distinction: Scrubbers vs. Separators

[ez-toc] Overview of Scrubbers vs Separators Operational Differences and Similarities Despite having the same purpose of cleaning and processing industrial streams, scrubbers operate on different principles as separators. These are used to extract particulate matter and gases from exhaust gases via direct contact with a liquid usually water. In gas treatment plants that focus on […]

Separating Water from Gas Industrial Separation Technologies

[ez-toc] Why Water-Gas Separation is Critical In many industrial processes—particularly in the oil, gas, and chemical sectors—separating water from gas is essential for maintaining system efficiency. Water contamination in gas streams can cause corrosion, reduced performance, and operational failures. Proper water-gas separation technologies help protect equipment, ensure smooth operations, and reduce maintenance costs. Understanding how […]

The Water Separator Collector

[ez-toc] The Importance of Water Separation Protecting Equipment from Water Damage Water, while a vital resource, can nevertheless be a formidable adversary to industrial, automotive, marine, and aviation equipment. In particular, the presence of water in systems where it’s not wanted can lead to corrosion, reduced efficiency, and, ultimately, premature failure. As a result, that’s […]

Pressure Control in Separator Systems

[ez-toc] Pressure Control in Separator Systems In separator operations, precision is prime. Precise pressure management permits for first-rate-tuning of the separation system, optimizing efficiency, and maximizing production output. Whether it’s adjusting strain tiers to deal with changes in feedstock composition or preserving constant strain to ensure regular operation, unique management guarantees dependable overall performance and […]

Pulsation Bottles

Enhancing Efficiency and Durability with Pulsation Bottles In the complex world of mechanical and hydraulic systems, efficiency and longevity often depend on small components. One such component is the pulsation bottle. Though modest in appearance, it plays a major role in boosting system performance across various applications. Whether it’s HVAC systems or hydraulic operations, pulsation […]

Understanding Pressure Vessel Failures

Pressure vessel failures are caused by corrosion, material defects, fatigue, design flaws, and operational errors. Preventing these failures requires regular inspections, proper design validation, corrosion-resistant materials, and strict adherence to ASME standards. This guide explains the top causes and practical prevention strategies used by industry experts. Introduction to Pressure Vessel Failures Pressure vessel failures can […]

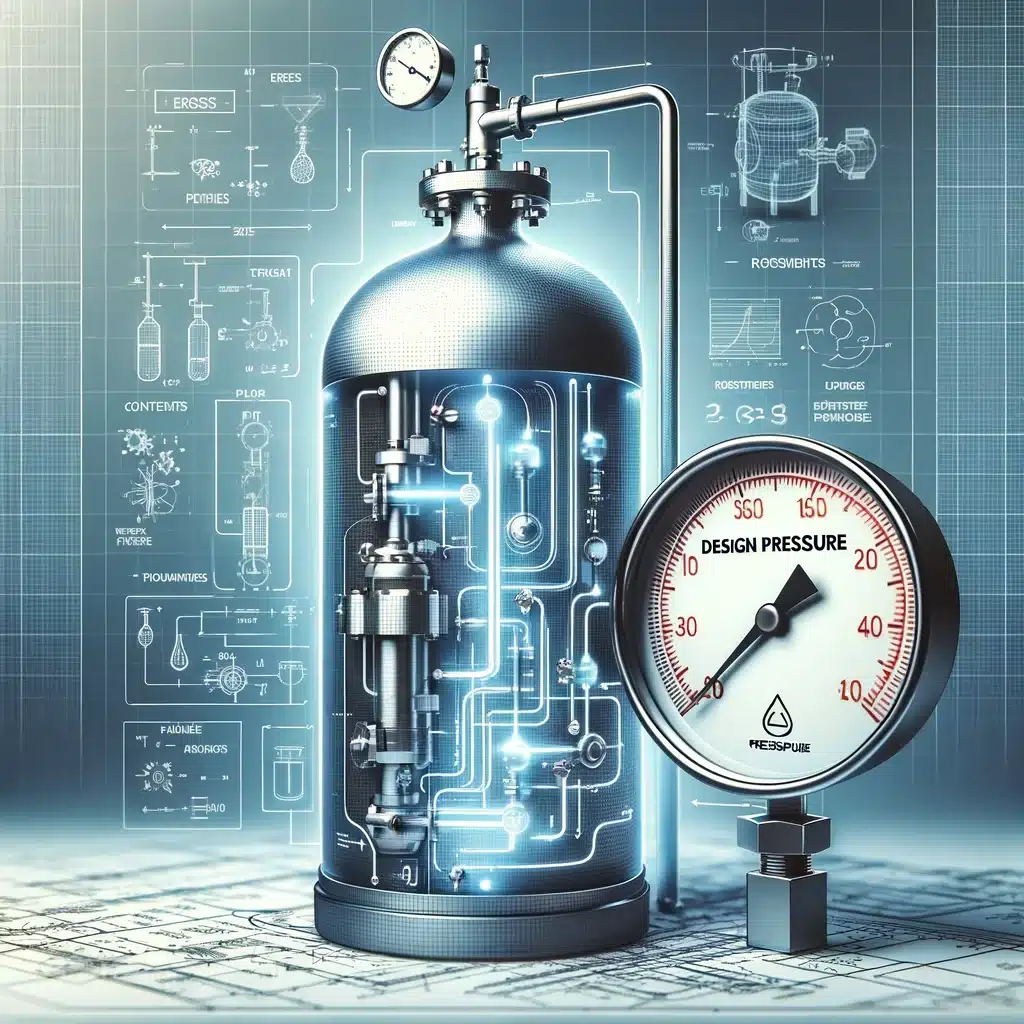

Operating Pressure vs Design Pressure: Your Essential Vessel Comparison Guide

Design pressure is the maximum pressure a vessel can safely handle. It’s a critical parameter in pressure vessel design, ensuring compliance, performance, and safety. Learn how to calculate it, what affects it, how it’s tested, and how Red River engineers apply it across industries. What is Design Pressure in Pressure Vessels? Design pressure is the […]

Important Points to be Considered While Designing a Pressure Vessel

Pressure vessel design involves engineering sealed containers to safely hold pressurized gases or liquids. It requires precise calculations, material selection, and compliance with codes like ASME Section VIII. This guide from Red River LLC covers core design principles, safety features, material options, and how we tailor vessels for industry-specific needs. Learn the fundamentals in our […]