Exploring the Challenges of Wet Scrubbers in Industrial Applications

Table of Contents

ToggleThe Challenges of Wet Scrubbers in Industrial Applications

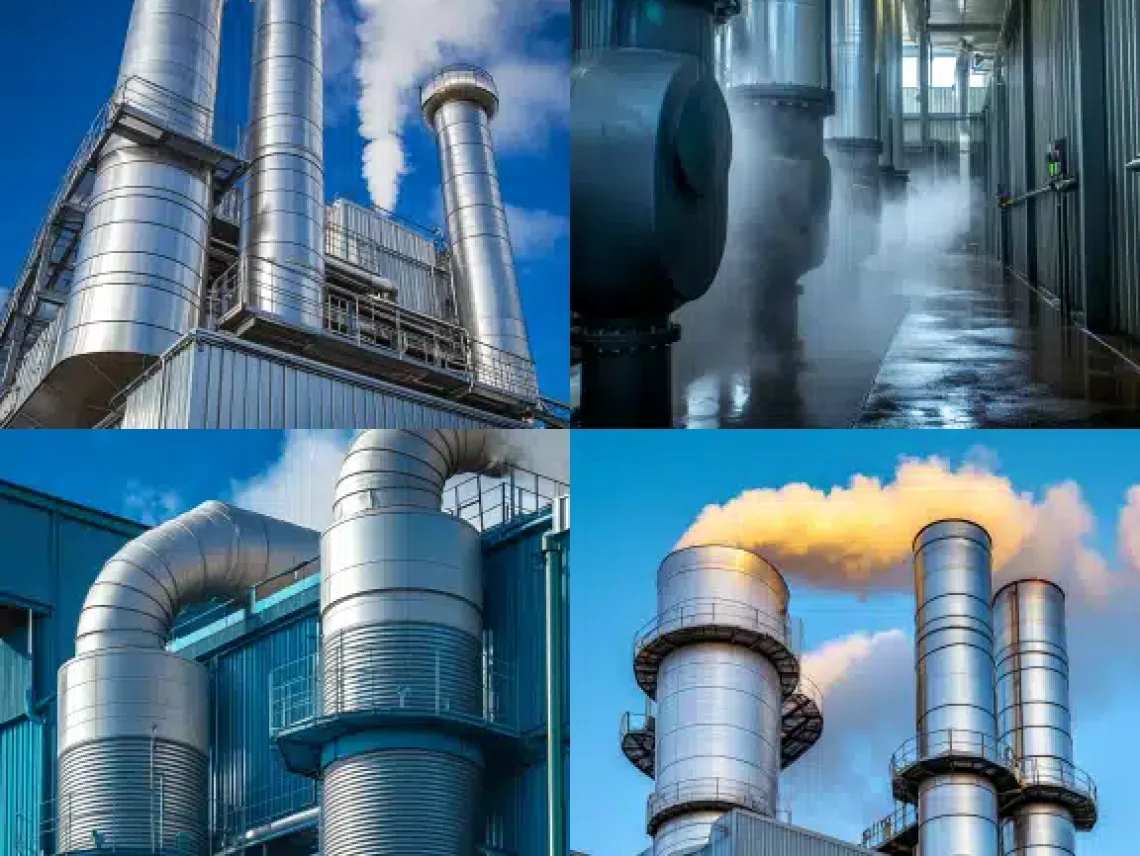

Wet scrubbers are critical devices in commercial enterprise air pollutant control, renowned for their effectiveness in getting rid of particulate matter quantity and gases from exhaust streams. However, like several generations, they arrive at precise challenges that industries must cope with to maximize their benefits at the same time as minimizing environmental impact and operational expenses. This article delves deeper into the number one annoying situation associated with wet scrubbers, their implications, and techniques for overcoming those boundaries efficiently.

The Challenges of Wet Scrubbers: High Water Consumption

Wet scrubbers rely on water or different liquid solutions as the primary scrubbing medium to capture pollutants from gas streams. This reliance on water effects in massive intake fees, which would pose several demanding situations:

- Operational Costs: Water usage is interpreted right away into operational charges, collectively with procurement, treatment, and disposal charges. Industries should price range for big water charges whilst planning scrubber installations and ongoing operations.

- Environmental Impact: In areas wherein water sources are scarce or in which strict guidelines govern water usage and discharge, excessive water consumption can gift environmentally demanding situations. Discharging wastewater from scrubber operations without the right remedy can bring about pollutants in water bodies and surrounding ecosystems.

- Maintenance and Monitoring: Managing water satisfactorily and ensuring adequate delivery for continuous scrubber operation requires diligent monitoring and renovation efforts. Proper chemical dosing, pH manipulation, and periodic cleaning of scrubber components are important to keep performance and follow regulatory standards.

Strategies to Mitigate Water Consumption in Wet Scrubbers

Despite the annoying conditions posed by using excessive water intake, industries can put into effect numerous techniques to optimize water usage and beautify the sustainability of wet scrubber operations:

Water Recycling Systems:

Implementing water recycling and reuse systems lets industries lessen clean water consumption and decrease wastewater discharge. Recirculating dealt with water in the scrubber device can notably decrease usual water consumption and operational charges.

Optimize Scrubber Design and Operation Parameters:

Fine-tuning scrubber layout parameters which include gasoline drift charges, liquid-to-fuel ratios, and scrubbing overall performance can help optimize water usage. Efficient use of water guarantees maximum pollutant removal at the same time as minimizing excess consumption.

Explore Alternative Scrubbing Technologies:

Depending on the precise emission profiles and operational necessities, industries can find out the possibility of a scrubbing era that requires less water or uses dry sorbents instead. Dry scrubbers, for example, cast off the need for liquid totally, lowering water-related traumatic situations.

Compliance with Water Regulations:

Industries must adhere to nearby and countrywide rules governing water utilization, discharge limits for pollutants in wastewater, and treatment requirements. Collaboration with environmental groups guarantees compliance and mitigates dangers related to environmental effects.

Need a reliable partner?

FAQ About the Challenges of Wet Scrubbers

Why do wet scrubbers eat lots of water?

Wet scrubbers use water as a scrubbing medium to capture pollutants through absorption or chemical response. The quantity of water required depends on factors including pollutant attention, fuel float charge, and scrubber layout.

How does high water consumption impact industries?

High water intake will grow operational fees, pose demanding situations in regions with water shortages, and call for effective wastewater control to prevent environmental impact.

Are there guidelines governing water utilization in moist scrubber operations?

Yes, industries ought to look at nearby rules concerning water utilization, discharge limits for pollution in wastewater, and the right treatment methods in advance of disposal.

What are alternative answers to mitigate water consumption in moist scrubbers?

Implementing water recycling structures, optimizing scrubber format and operation parameters, and exploring dry scrubber generation can assist reduce water intake in industrial packages.

Can excessive water intake affect scrubber efficiency?

Yes, inadequate water delivery or mistaken water control can impact scrubber performance, lowering pollutant removal effectiveness and doubtlessly leading to non-compliance with emission requirements.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.