How Does a Glycol Expansion Tank Work?

Table of Contents

ToggleWhat Is a Glycol Expansion Tank?

A glycol expansion tank is a vital component in closed-loop hydronic HVAC systems. It serves one primary function: to maintain proper pressure and fluid balance as the system heats and cools. Expansion tanks absorb the expansion of glycol-based heat transfer fluids, preventing pressure spikes that could otherwise damage system components.

Unlike typical water expansion tanks, glycol expansion tanks are built to accommodate the unique chemical properties of glycol—a substance with antifreeze characteristics used in many HVAC applications. These tanks are pressurized and equipped with a bladder or diaphragm that separates the air cushion from the glycol fluid. This separation allows the tank to compress the air and absorb expanded fluid volume without allowing air and liquid to mix.

Glycol expansion tanks are most commonly found in:

- Commercial buildings with large-scale heating and cooling systems

- Industrial process heating setups

- Residential hydronic radiant floor heating systems in cold regions

Their key benefit is helping maintain safe operating pressure, which reduces wear and tear on HVAC pumps, valves, and piping.

Why Is Glycol Used in HVAC Systems?

In HVAC systems, particularly those exposed to low ambient temperatures, glycol serves as a safeguard. It’s mixed with water to create a heat transfer fluid that won’t freeze under typical operating conditions. This makes glycol ideal for regions where subfreezing temperatures can compromise system integrity.

Main Benefits of Glycol in HVAC Applications

- Freeze Protection: Glycol prevents freezing in exposed sections of piping and equipment such as coils and chillers.

- Corrosion Inhibition: Most glycol products contain additives that reduce corrosion in system components.

- Reduced Maintenance: Systems with glycol require less frequent maintenance related to freeze-thaw cycles.

- Improved Longevity: Protecting components from freezing increases the overall lifespan of the system.

Ethylene glycol and propylene glycol are the two most common types used in HVAC systems. While ethylene glycol offers better heat transfer performance, it is toxic and requires special handling. Propylene glycol, though less efficient, is non-toxic and preferred in applications where human exposure is a concern.

For further reading, ASHRAE offers an excellent technical overview of glycol applications in HVAC systems (ASHRAE Guide).

How the Glycol Expansion Tank Operates

The Science of Thermal Expansion

As glycol heats up, it expands. Without a buffer to absorb this added volume, pressure builds inside the closed-loop system. This can trigger relief valves, strain fittings, and even damage heat exchangers. The expansion tank serves as a controlled reservoir for this expanded fluid.

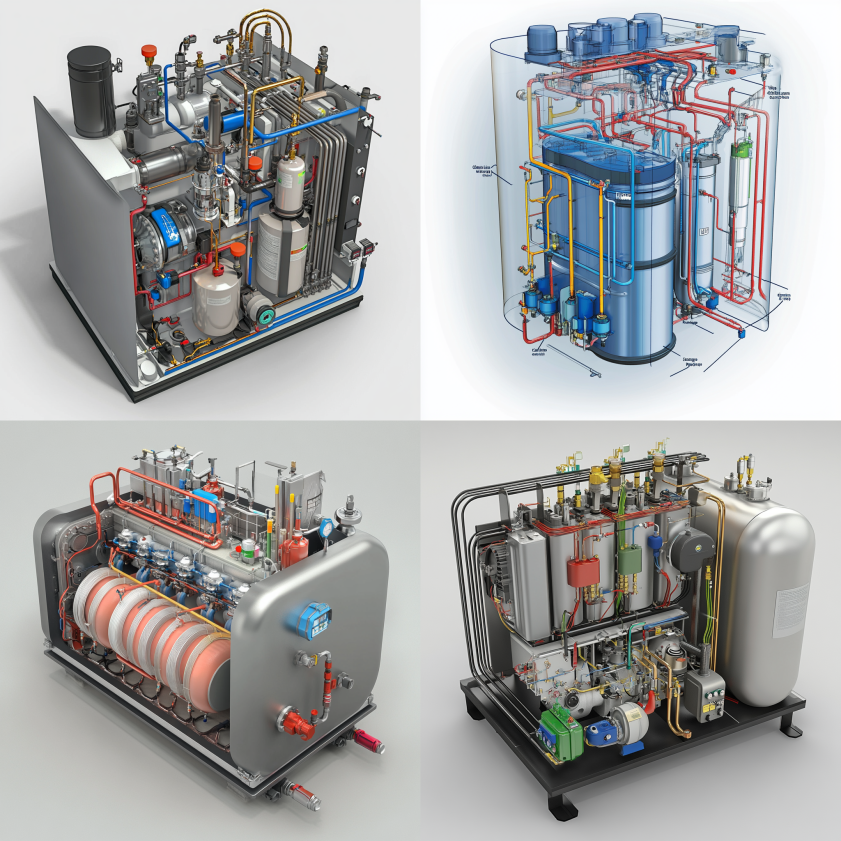

Key Components of a Glycol Expansion Tank

- Steel or Composite Tank Body: Houses the internal mechanisms and fluid.

- Diaphragm or Bladder: Separates the glycol fluid from the air cushion to prevent mixing.

- Air Chamber: Provides compressibility for fluid expansion.

- Pressure Gauge and Valve: Allows monitoring and adjustment of internal pressure.

Operating Process

- Start-Up Phase: The system is filled with glycol/water mix and pressurized.

- Heating Phase: As the system heats up, glycol expands and pushes against the diaphragm.

- Absorption Phase: The tank’s air cushion compresses, accepting the increased fluid volume.

- Cooling Phase: As the system cools, the glycol contracts, and the air pushes the fluid back into the system.

This cyclical process ensures the system remains at optimal pressure throughout temperature fluctuations. Without this mechanism, systems would be forced to rely on pressure relief valves, which can lead to fluid loss and damage over time.

Closed-Loop vs. Open-Loop Systems

Not all HVAC systems are built the same. Glycol expansion tanks are specifically designed for closed-loop systems, where the fluid is recirculated rather than consumed or replaced.

Closed-Loop Systems:

- The fluid remains within the piping circuit.

- Common in radiant floor heating, baseboard heating, and chilled water loops.

- Glycol is crucial in preventing freeze-ups in sections exposed to the outdoors.

- A sealed environment helps reduce contamination and evaporation.

Open-Loop Systems:

- The fluid is introduced and discharged (e.g., domestic hot water or irrigation).

- Expansion is typically managed with atmospheric pressure tanks or air separators.

- Glycol is not commonly used due to potential contact with potable water.

It’s important to understand the difference when designing, retrofitting, or maintaining HVAC systems. Using a glycol expansion tank in an open-loop system is both unnecessary and potentially harmful to water quality.

For more technical distinctions, the U.S. Department of Energy provides insights on system design standards (DOE HVAC Basics).

Signs of a Faulty Glycol Expansion Tank

Like any mechanical component, glycol expansion tanks can fail over time. Recognizing early warning signs helps prevent costly repairs or system failures.

Common Symptoms:

- Fluctuating System Pressure: Inconsistent pressure readings may signal a failed diaphragm or an improperly pressurized tank.

- Relief Valve Discharges: Constant dripping or discharging suggests the tank isn’t absorbing the expanded fluid.

- Air Noises in Pipes: Gurgling sounds can indicate air intrusion from a compromised bladder.

Visible Corrosion or Leaks: External damage or staining often points to internal failure. - Waterlogged Tank: A failed diaphragm causes the tank to fill with fluid, eliminating its compressibility.

Causes of Failure:

- Age and wear

- Incorrect tank sizing

- Excessive system pressure

- Lack of annual maintenance

Replacement is typically straightforward and can prevent secondary damage. If your system shows any of these signs, it’s wise to consult an expert. Red River offers support in system diagnostics and maintenance planning.

In Summary: Understanding the Heart of Closed-Loop Pressure Management

A glycol expansion tank is more than just a pressurized container—it’s the backbone of fluid pressure control in closed-loop HVAC systems. These tanks absorb thermal expansion, prevent dangerous pressure surges, and extend the life of system components. When glycol is used as the heat transfer medium, it adds freeze protection, making these tanks indispensable in colder climates and sensitive installations.

Whether you’re managing a radiant floor heating system, a rooftop HVAC loop, or an industrial chiller, understanding how a glycol expansion tank works helps you ensure system reliability and long-term efficiency.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. What is the purpose of a glycol expansion tank?

A glycol expansion tank absorbs the increased volume of glycol when it heats and expands, maintaining safe pressure levels in a closed-loop HVAC system.

2. Can a standard water expansion tank be used with glycol?

No, glycol systems require compatible materials and pressures. Glycol tanks are designed to resist corrosion and chemical breakdown from antifreeze solutions.

3. How do I know if my glycol expansion tank is properly sized?

Tank size depends on total system volume, fluid type, operating pressure, and temperature range. An HVAC professional or manufacturer’s sizing chart should be consulted.

4. How often should the expansion tank be checked?

At least once a year. Inspections should include checking the internal air pressure, diaphragm condition, and ensuring there are no leaks or corrosion.

5. What’s the difference between bladder and diaphragm tanks?

Both separate the air and fluid chambers. Bladder tanks use a replaceable balloon-like bladder; diaphragm tanks use a fixed membrane.

6. Is glycol toxic?

Ethylene glycol is toxic and must be handled carefully. Propylene glycol is non-toxic and safe for use in systems with potential human exposure.

7. Can glycol go bad over time?

Yes. Over time, glycol can degrade and lose its protective additives. It’s advisable to test fluid quality every few years and replace it if necessary.

8. How do I set the correct air pressure in the tank?

The tank’s air charge should match the system fill pressure when the system is cold. A gauge and air pump may be needed for adjustments.

Key Takeaways

- Glycol expansion tanks regulate pressure in closed-loop systems by absorbing fluid expansion.

- Glycol is essential for freeze protection and corrosion resistance in HVAC setups.

- Expansion tanks contain air chambers and diaphragms to separate fluid and gas.

- Closed-loop systems benefit most from glycol tanks; open systems require different approaches.

- Regular inspection and maintenance ensure long-term system health.

- Sizing, pressure settings, and compatibility are critical to correct operation.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.