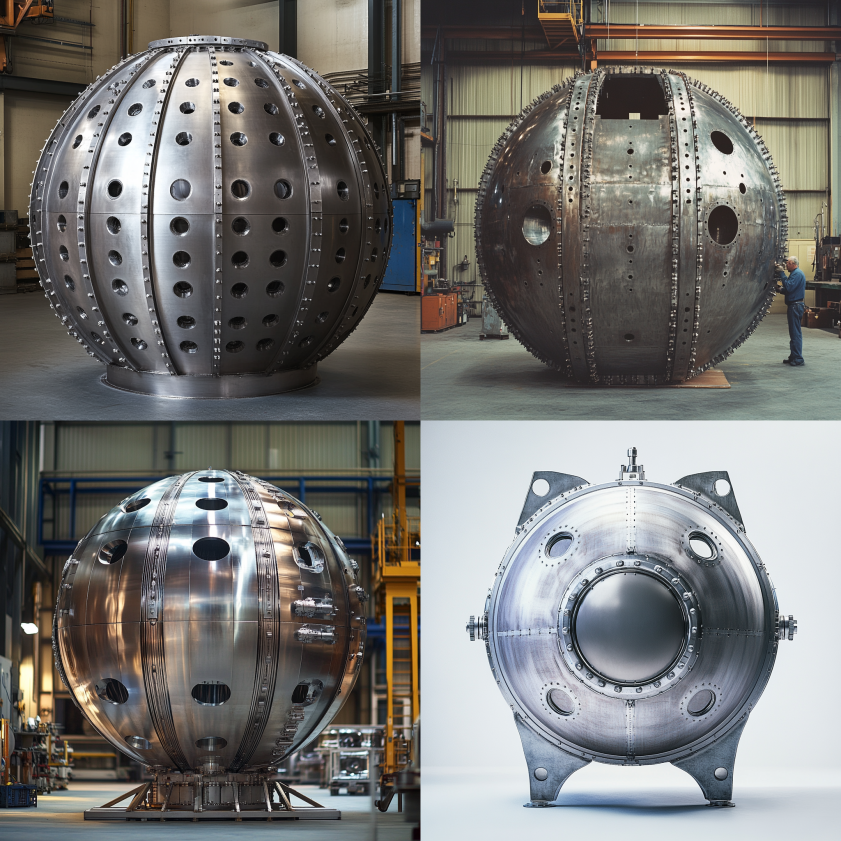

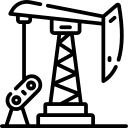

Red River fabricates High-Temperature Reactor Vessels engineered to support the demanding requirements of defense research and controlled testing environments. These vessels are built for reliability, structural integrity, and consistent performance under extreme temperature and pressure conditions.

Contact us today to request a quote for high-temperature reactor vessel fabrication.

High-temperature reactor vessels must manage thermal cycling, pressure fluctuations, and specialized chemical environments. Our fabrication capabilities support advanced materials, reinforced structures, and precision requirements needed for sensitive research work.

Defense R&D projects often require fully customized reactor vessels that meet specific testing parameters, instrumentation setups, or thermal performance expectations. Our engineering team develops designs to align with your research goals and operational requirements.

Our fabrication capabilities support complex assemblies and strict quality requirements suitable for critical environments. Each vessel is manufactured following robust quality practices and ASME standards.

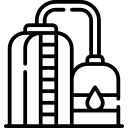

We begin by evaluating testing parameters, temperature ranges, pressure profiles, and instrumentation needs.

Engineers develop a vessel design focused on thermal performance, structural safety, and integration into your testing environment.

Vessels are manufactured using high-grade alloys and precision welding processes suitable for high-temperature applications.

All reactor vessels undergo pressure testing, NDT inspections, and project-specific documentation for validation.

Our team is familiar with the requirements of sensitive research programs and provides fabrication aligned with performance criteria and quality standards.

Materials, welds, and structural designs are selected to withstand sustained thermal and mechanical stress.

Every vessel is engineered to match your testing methods, instrumentation, and integration layout.

We design vessels with temperature capabilities based on your specified operating conditions and required materials.

Yes. We can engineer vessels to support combined operational stresses depending on your testing requirements.

Yes. Vessels can be manufactured to meet ASME Boiler and Pressure Vessel Code requirements.

Yes. We can include custom ports for gauges, sensors, thermocouples, and monitoring equipment.

We provide material certifications, weld records, pressure test reports, NDT results, and project-specific documentation.

test

test

test

test

test

test

Red River is ready to support your defense research program with reactor vessels engineered for high-temperature and high-performance environments.