What Are the Three Types of Metal Fabrication?

Table of Contents

ToggleTypes of Metal Fabrication: An Overview

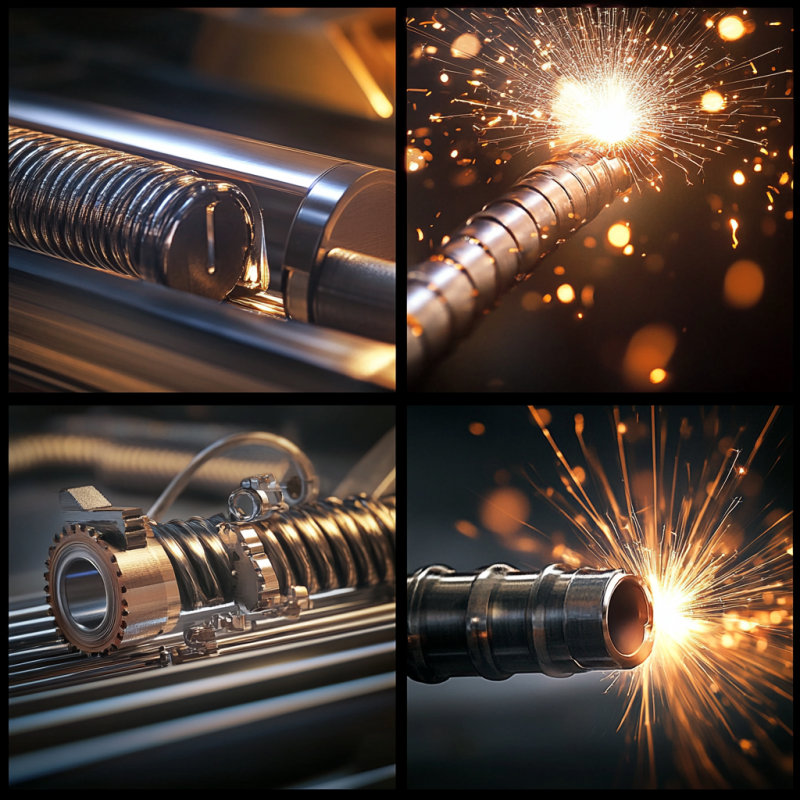

At its core, metal fabrication refers to processes that manipulate metal materials into parts, components, or finished products. The techniques vary depending on the project’s design, material, precision requirements, and intended use. The three main types of metal fabrication are:

- Cutting: Separating metal into desired shapes and sizes

- Forming: Shaping metal without removing material

- Joining: Assembling metal pieces into a unified structure

Many projects use a combination of these techniques to achieve their final form.

Cutting: Shaping Metal by Separation

Cutting is the process of removing parts of the metal to create specific shapes or sizes. It is often the first step in fabrication and is crucial for preparing raw materials to the correct dimensions. The precision and quality of cutting directly impact the success of subsequent fabrication steps.

Common Cutting Techniques

There are several cutting methods in metal fabrication, each suited to different materials, thicknesses, and project scales:

- Laser Cutting: Uses a focused laser beam to cut metal with high precision and clean edges. Ideal for intricate designs and thin to medium-thickness metals.

- Plasma Cutting: Uses ionized gas (plasma) at high temperatures to slice through thick metal plates efficiently.

- Waterjet Cutting: Employs a high-pressure stream of water mixed with abrasive particles to cut metals without heat distortion. Great for heat-sensitive materials.

- Shearing: A mechanical process that cuts metal sheets with straight-line blades, much like scissors. Used for simple straight cuts.

Applications of Cutting

Cutting is fundamental in industries ranging from aerospace to construction. For example, automotive manufacturers use laser cutting to shape body panels, while heavy machinery companies rely on plasma cutting for thick steel parts.

Benefits of Cutting

- High precision and repeatability

- Versatility in handling different metals and thicknesses

- Minimal waste with efficient material use

If you’re curious about related fabrication services or want to explore how metal cutting can improve your project, Red River Team offers expert metal fabrication solutions tailored to your needs.

Forming: Changing Metal Shape Without Removing Material

Forming is a process that reshapes metal without cutting away any material. Instead of removing parts, forming bends, rolls, or stretches the metal into the desired shape. This technique preserves the metal’s integrity and often strengthens it through work hardening.

Popular Forming Methods

- Bending: Using machines like press brakes, metal sheets are bent into angles or curves. Common in manufacturing brackets, frames, and enclosures.

- Rolling: Passing metal through rollers to create curves or cylindrical shapes, like pipes or tubes.

- Stamping: A high-speed process where metal sheets are pressed into molds or dies to produce shapes or patterns, widely used in mass production.

- Forging: Heating metal to make it pliable and then hammering or pressing it into shape. Produces very strong parts like engine components.

How Forming Alters Metal Properties

Forming not only changes the shape but can also affect the metal’s physical properties. Processes like forging improve strength by aligning the grain structure, while bending can cause work hardening, increasing durability in specific areas.

Forming in Real Life

Forming techniques are integral in industries such as automotive manufacturing, aerospace, and consumer electronics. For instance, the curved body of a car door or the casing of a smartphone often involves metal forming.

Joining: Assembling Metal Parts into Final Products

Joining is the process of combining separate metal parts into one final product. Unlike cutting or forming, joining focuses on uniting pieces through various mechanical or chemical methods.

Common Joining Techniques

- Welding: Using heat and/or pressure to fuse metal parts together, creating a strong, permanent bond. Types of welding include MIG, TIG, and arc welding.

- Soldering and Brazing: These involve melting a filler metal to join parts without melting the base metals. They are used for thinner or delicate components.

- Mechanical Fastening: Includes bolts, screws, rivets, and clamps to hold parts together. This method allows for disassembly and repairs.

Importance of Joining

Joining provides structural integrity and flexibility in design. It enables complex assemblies like vehicle frames, industrial machinery, and construction elements. The right joining method ensures safety, strength, and durability.

Industry Examples

Construction beams welded together to form building skeletons, or precision welding used in aerospace to create lightweight, strong aircraft parts, all demonstrate the importance of joining.

For expert advice on metal joining and complete fabrication services, feel free to contact Red River Team to discuss your project requirements.

Understanding the Core Types of Metal Fabrication

Mastering the types of metal fabrication provides essential insight into how metal transforms from raw sheets or bars into precise, functional parts. Cutting, forming, and joining each bring unique advantages and techniques that cater to various needs—from small custom projects to large-scale industrial manufacturing.

Whether you are involved in manufacturing, engineering, or simply curious about how metalwork shapes the world around us, recognizing these fundamental processes is the first step toward deeper knowledge.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequent Ask Question

1. What is metal fabrication?

Metal fabrication involves cutting, shaping, and assembling metal into parts or products used across various industries.

2. Which industries rely most on metal fabrication?

Industries such as construction, automotive, aerospace, electronics, and manufacturing heavily depend on metal fabrication.

3. What is the key difference between forming and cutting?

Cutting removes parts of the metal, while forming reshapes it without removing any material.

4. Are all three types of metal fabrication used in one project?

Yes, many fabrication projects combine cutting, forming, and joining to achieve the final product.

5. How do I choose the right metal fabrication process?

The choice depends on factors like material type, thickness, design complexity, and production volume.

6. Is metal fabrication dangerous?

Proper safety measures and equipment are essential, as fabrication often involves sharp tools, heat, and heavy machinery.

7. Can metal fabrication be automated?

Yes, many fabrication techniques use automated machinery like CNC lasers and robotic welders to increase precision and efficiency.

8. Where can I learn more about metal fabrication processes?

Industry websites, technical courses, and companies like Red River Team offer valuable resources and services.

Key Takeaways

- The types of metal fabrication—cutting, forming, and joining—are the backbone of metal manufacturing.

- Cutting separates metal to shape raw materials with techniques such as laser, plasma, and waterjet cutting.

- Forming reshapes metal without removing material using bending, rolling, stamping, and forging.

- Joining assembles parts via welding, soldering, brazing, or mechanical fastening.

- Each method serves unique purposes and is often combined for complex projects.

- Choosing the right process depends on the material, design, and application.

Table of Contents

ToggleRelated Blog Post

- Is welding a type of fabrication?

- What trade is metal fabrication?

- What is a metal workshop called?

- What are 5 examples of fabrication?

- What are the 3 main fabrication techniques?

- What is the process of making metal called?

- What is the 6 most common types of metal working?

- What are four common materials used in metal fabrication?

- What is the difference between sheet metal and fabrication?

- What is the difference between machinist and metal fabrication?

- What is the difference between metal fabrication and manufacturing?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Need action? Ready to Get Started?

We are here to make it happen. Request a qoute!