Table of Contents

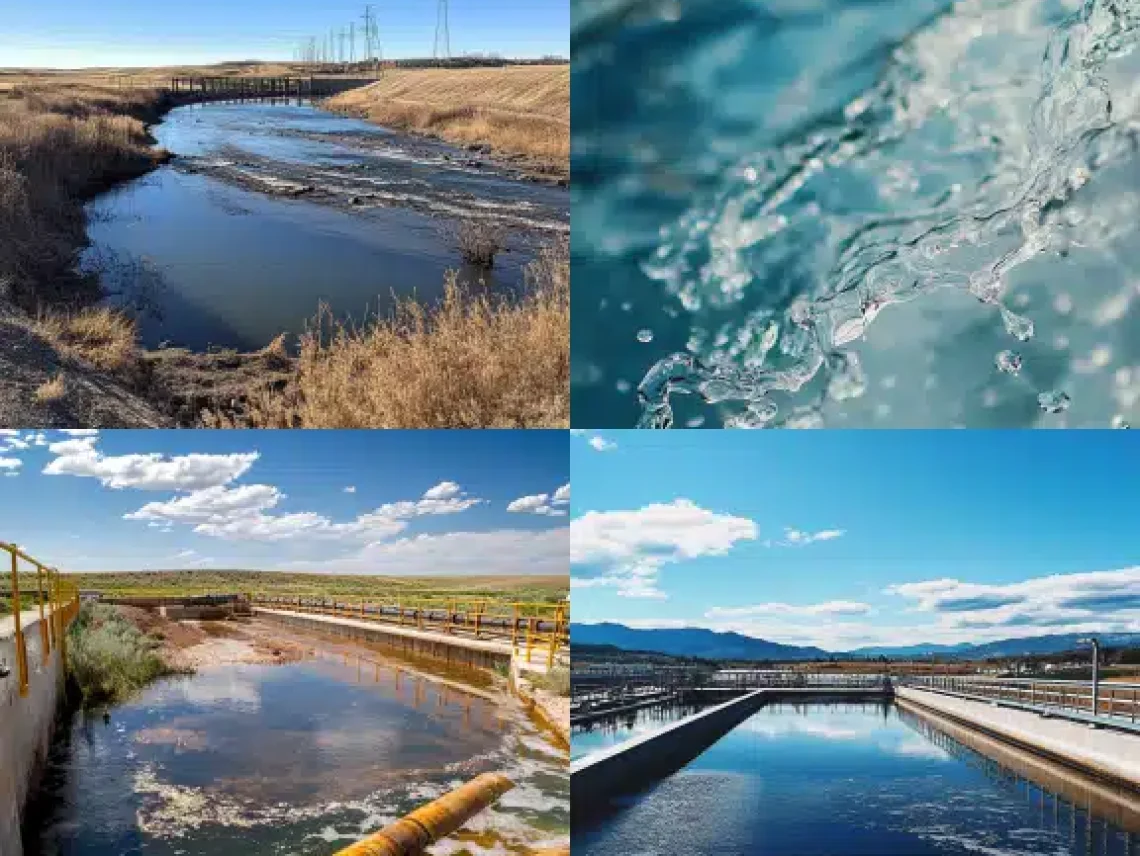

ToggleConductivity in drinking water is a key indicator of water quality, measuring how easily water can conduct electricity due to dissolved salts, metals, and other charged particles. High conductivity levels often signal contamination and potential health risks, while low levels indicate cleaner, safer water. Understanding what affects conductivity — and how to keep it within safe limits — is essential for both households and industries. At Red River, we help ensure that water systems meet EPA-recommended conductivity standards for safety and compliance. At Red River, we help ensure that water systems meet safe drinking water standards and EPA-recommended conductivity thresholds for safety and compliance.

One gauge for determining the quality of water is conductivity. The EPA regulates the allowance of dissolved material in the water through their conductivity standards on drinking water. This is measured using specialized instruments that can determine how well the water transmits electrical currents. Knowing this measurement can actually enable one to ensure safety in water usage. Too high a reading might indicate too many salts or pollutants, which may be hazardous to health.

At Red River, we work with the oil and gas, power generation, and biogas industries to ensure water systems, including pressure vessels and filtration components, meet and surpass EPA guidelines for conductivity of water. By staying at safe conductivity levels, businesses safeguard the public but also do so while remaining under EPA thresholds for drinking water conductivity.

So why’s conductivity a big deal? Well, the levels of conductivity give you a quick, dirty insight into the presence of dissolved solids in the water. If conductivity exceeds the EPA permissible levels for potable water, contamination might very well be the issue—be it industrial runoff or some other natural occurrence—which could pose a hazard to public health.

Red River ensures our pressure vessels are conducting safely in water systems, staying within allowed ranges. We bring American values—morals, family, work ethic, and self-reliance—to each project to ensure your systems operate safely and efficiently.

The EPA does not set a specific maximum contaminant level (MCL) for conductivity, but it closely monitors substances that affect it — such as dissolved salts, metals, and organic material. In most water treatment systems, a conductivity reading of 500 µS/cm or lower is considered ideal, while readings above 1,000 µS/cm may indicate excessive dissolved solids or possible industrial contamination. Regular monitoring helps detect early signs of pollution and maintain safe, drinkable water. Regular monitoring — combined with pressure vessel certification and compliance — helps detect early signs of pollution and maintain safe, drinkable water.

Conductivity standards imposed for community water systems include regular tests and reports on water. Community water providers have to ensure that the water supplied has acceptable thresholds of contaminants that impact conductivity, for example, salts and heavy metals. This ensures the water consumed safely meets the EPA’s guidelines on water conductivity.

To keep conductivity in safe ranges, reduce sources of dissolved solids and test water regularly. Installing reverse osmosis or ion exchange filtration systems can significantly lower salts and contaminants that cause high conductivity. Periodic maintenance ensures filtration efficiency and long-term water safety.

Many industrial facilities also integrate pressure vessels in industrial water treatment to optimize filtration and meet strict regulatory guidelines.

Testing the conductivity of your water is very simple. You can either purchase a conductivity meter or a TDS (total dissolved solids) meter at your local hardware store or buy one online. Using that, you can measure the electrical conductivity of the water, which gives you an idea of how high dissolved salts and minerals are in the water. Testing frequently will assure you that your water is well within the EPA’s recommended conductivity levels.

Highly conductive water? Get a water filtration system. Water systems like reverse osmosis and ion exchange filters can significantly lower dissolved salts and contaminants that cause high conductivity, making it safe to use. Such filtration approaches can ensure that water quality is sufficient for residential consumers and industrial users alike.

At Red River, we offer personalized services to industrial customers to ensure efficient management of water quality. Our pressure vessels and filtration systems are designed and manufactured according to EPA specifications for your water systems to ensure safe conductivity levels. Contact us for professional guidance and customized water solutions.

Boiling water does not significantly reduce conductivity because dissolved salts and minerals remain after boiling. Filtration methods like reverse osmosis are more effective.

Many bottled water brands aim for conductivity levels below 250 µS/cm for taste and purity. This is well below the general safety threshold for drinking water.

Conductivity measures how well water conducts electricity, while TDS (total dissolved solids) measures the concentration of dissolved ions. Higher TDS usually means higher conductivity, but the two values are expressed differently.

Conductivity in drinking water is basically the ability of water to conduct electrical current. Conductivity and concentration of dissolved ions such as salts, metals, and other charged particles are directly related. This matters because high levels of conductivity may indicate the existence of certain pollutants or contaminants that could impact water quality. While conductivity itself is harmless, it is a major indicator of the general purity of the water and may suggest the possible existence of substances that need regulation, such as heavy metals or high salinity levels.

There is no specific MCL of conductivity required by the EPA for drinking water, although it must be minimal. Most treatments for water plant installations aim to keep it at 500 µS/cm or less, although it depends on the origin of the water along with the discretion of the authority running it. Conductivity values of more than 1,000 µS/cm may imply that dissolved solids are too high, pose health hazards, or suggest industrial pollutants are causing contamination.

High conductivity in water stresses water treatment systems. It indicates increased dissolved minerals or contaminants, adding more load to the filtration systems. Treatment processes, like reverse osmosis or ion exchange, might have to work harder or more frequently to eliminate solids from the water. Industrial operating conditions leading to high conductivity can cause scaling, corrosion, or buildup inside pressure vessels and pipes, reducing efficiency and increasing maintenance costs.

Water conductivity per se poses no health risk. However, high values often suggest dissolved salts, heavy metals, or industrial contaminants in water, which are hazardous to health if they exist individually. When values are considerably different from acceptable levels specified by the EPA, it is prudent to test for specific harmful contaminants like lead, mercury, or nitrates, which might pose health hazards if consumed over time.

The best way to decrease conductivity in drinking water is by using a reverse osmosis or ion exchange water filtration system. Reverse osmosis filters are particularly good at removing a wide range of dissolved solids, including salts and metals that contribute highly to conductivity. Testing your water periodically and maintaining the filtration system properly ensures that conductivity remains within the safe range. Advanced filtration systems will surely reduce the risk of unfavorable conductivity levels in an industrial application, and inspecting pressure vessels frequently helps maintain water quality.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.