Table of Contents

Toggle

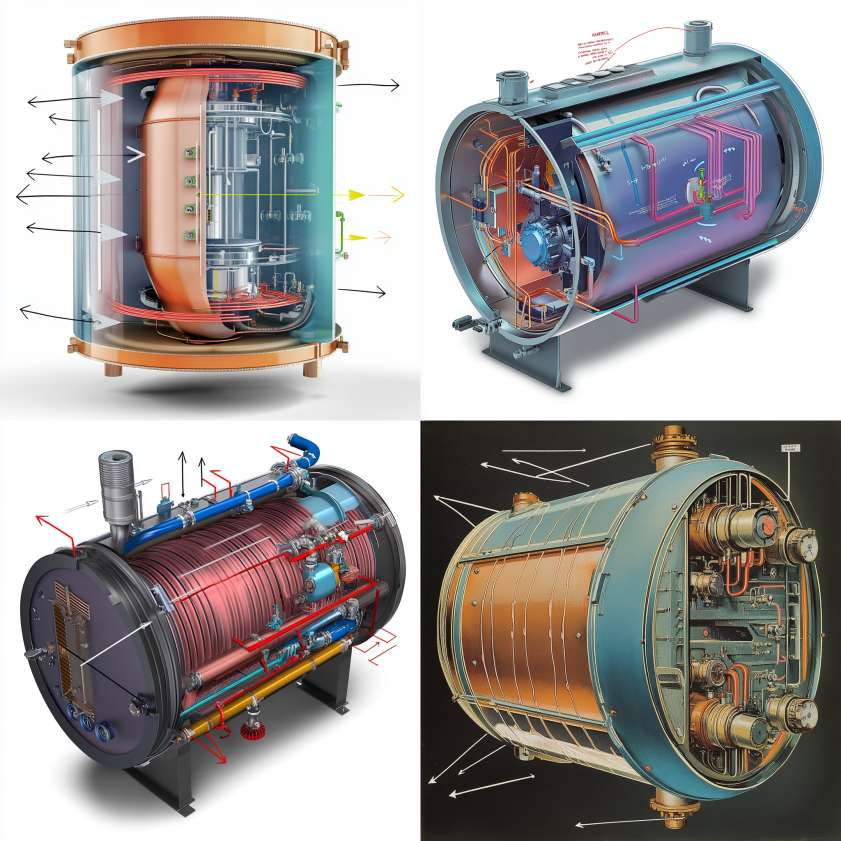

An expansion tank is a crucial safety device in modern plumbing and heating systems. But what happens when an expansion tank fails? Ignoring the warning signs can lead to severe pressure problems, system shutdowns, leaks, and even structural damage to your home. In this guide, you’ll learn the exact consequences of expansion tank failure, how to spot trouble early, and what steps to take for safe, efficient heating. If you’re troubleshooting boiler issues, it’s vital to understand how this small component protects your entire system—and how to respond when things go wrong.

The first step in prevention is knowing what to look for. Expansion tank failure often presents clear warning signs, including:

Frequent drops or surges in boiler pressure

Water leaks around the expansion vessel or in the boiler room

Strange banging or knocking noises, known as water hammer

Boiler error codes and unexpected shutdowns

Unusual activity from the pressure relief valve

To explore more warning signs, visit this detailed guide to combi boiler expansion vessel malfunction.

When an expansion tank fails, system pressure can swing dangerously high. This triggers the pressure relief valve, causing water to escape and reducing system efficiency. Prolonged failure can damage critical boiler components, such as the heat exchanger, pumps, and valves. For an in-depth look at pressure-related risks, read about what happens if there’s too much pressure inside the boiler.

Key steps to take if you suspect failure:

Turn off your boiler and allow it to cool

Inspect the expansion tank for leaks or signs of corrosion

Check the pressure gauge—if it won’t hold steady, your tank may be compromised

If water emerges from the air valve, the diaphragm is likely ruptured

Call a certified heating professional for a thorough inspection

For expert guidance, review this comprehensive guide to recharging pressure vessels.

Expansion tank failure can occur due to several factors:

Ruptured internal diaphragm

Loss of air charge over time

Corrosion or physical damage

Incorrect sizing or installation

If the diaphragm fails, water and air mix, causing the tank to become waterlogged—a “dead leg” that no longer absorbs pressure changes. This increases the risk of leaks, inefficient heating, and even system lockout. For a deeper technical dive, see detecting a faulty expansion vessel.

Learn more about the science behind expansion tanks and water pressure from Wikipedia and the U.S. Department of Energy.

Proactive maintenance is the best defense. Here’s how to avoid costly problems:

Schedule an annual inspection with a qualified technician

Regularly check vessel air pressure (usually around 1 bar)

Look for leaks, pressure drops, or abnormal noises

Replace tanks according to recommended schedules—explore replacement frequency

For more details on maintenance and signs of trouble, read about troubleshooting leaky expansion vessels and whether expansion vessels should be filled with water.

Expansion tanks play a vital role in preventing pressure spikes, leaks, and costly damage. When an expansion tank fails, the risks to your heating system and property are significant—but with proper maintenance and timely repairs, you can stay safe and efficient. Never ignore warning signs, and always seek professional help for diagnosis or repairs.

If you need expert help diagnosing, repairing, or maintaining your expansion tank, reach out to Red River’s experienced team today. We specialize in American-made pressure vessels and comprehensive heating system solutions—contact us now for a safer, warmer home.

If the tank fails, it can’t absorb water expansion, causing system pressure to rise, relief valves to trigger, leaks, and possible boiler shutdown or damage.

Signs include pressure swings, water leaks, strange noises, and water coming from the air valve. Read more about detecting faulty expansion vessels.

Yes, without pressure absorption, sudden surges can create loud banging or knocking sounds in your pipes. Learn about water hammer

Most repairs should be left to professionals. If the diaphragm is ruptured or the tank is waterlogged, replacement is usually necessary.

Lifespan varies, but most last 5–10 years. Follow manufacturer guidelines and check out the replacement schedule.

Common causes include loss of air charge, corrosion, physical damage, or normal wear and tear.

Expansion tanks handle heating system pressure changes, while pressure vessels can be used in broader applications—read more on Wikipedia.

Yes, in most modern closed heating systems. Check with your local building regulations for specifics or see U.S. Department of Energy.

A failed expansion tank causes dangerous pressure spikes and leaks.

Early warning signs include pressure swings, leaks, and water hammer.

Annual inspections and timely replacement prevent costly repairs.

Most failures require replacement, not repair.

Internal and external resources provide vital troubleshooting info.

Always contact a qualified technician for maintenance and repairs.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.