Pressure vessels are built to handle high-pressure fluids safely, while water tanks store fluids at low or atmospheric pressure. Choosing the right type ensures system efficiency, safety, and compliance with regulatory standards.

Understanding Pressure Vessels vs. Water Tanks: A Critical Safety and Performance Decision

When it comes to fluid storage and system efficiency, understanding the difference between pressure vessels vs. water tanks is more than semantics it’s a matter of safety, performance, and regulatory compliance. While these components may look similar, they serve very different purposes across industrial, commercial, and residential applications.

At Red River, we understand how critical it is to match the right solution with the right need. With decades of experience designing and fabricating custom pressure vessels, our team operates with a values-driven approach rooted in quality, integrity, and American craftsmanship. We’re not just manufacturers we’re long-term partners.

In this guide, we’ll walk you through:

- What pressure vessels and water tanks are

- Where and how each is used

- Key differences in design, construction, and safety

- How to choose the right solution for your system

For a broader overview of what we do, visit our capabilities and solutions pages.

What Is a Pressure Vessel?

Definition and Function

A pressure vessel is a container engineered to hold gases or liquids at pressures significantly different from ambient pressure. Because failure can be catastrophic, these vessels are built under strict engineering controls and codes such as the ASME Boiler and Pressure Vessel Code.

Pressure vessels are designed to safely store energy in pressurized form to regulate flow, maintain system pressure, or absorb fluctuations. Learn more in our detailed guide on understanding pressure vessels: definitions and thresholds.

Common Applications

Pressure vessels are essential in high-performance industries:

- Oil & Gas: Refining, separation, and compression processes handling hydrocarbons under pressure

- Chemical Processing: Reactors, storage vessels, and separators handling reactive compounds safely

- Water Treatment: Reverse osmosis systems, filters, and chemical dosing applications

Explore industry-specific use cases in our article on pressure vessels in industrial applications or browse our ASME-certified pressure vessels.

What Is a Water Tank?

Definition and Purpose

A water tank is designed primarily for storing water at or near atmospheric pressure. Unlike pressure vessels, water tanks prioritize volume and availability rather than pressure containment.

While some tanks experience minor pressure from gravity or low-duty pumps, they are not designed for sustained or fluctuating pressure. This distinction is critical, as explained in our post on understanding water tanks as pressure vessels.

Common Uses

Water tanks are widely used across residential, commercial, and agricultural sectors:

- Residential Water Supply: Water tanks ensure households have steady potable water supply, especially in off-grid areas

- Fire Suppression Systems: These water tanks hold large volumes for emergency use in sprinkler systems

- Agricultural Storage: Farmers use water tanks to irrigate crops, hydrate livestock, or collect rainwater

For related insights, see pressure vessels for domestic water systems and why you might need a pressure tank.

Key Differences Between Pressure Vessels and Water Tanks

Structural Design

The biggest difference lies in structural design when comparing pressure vessels vs. water tanks.

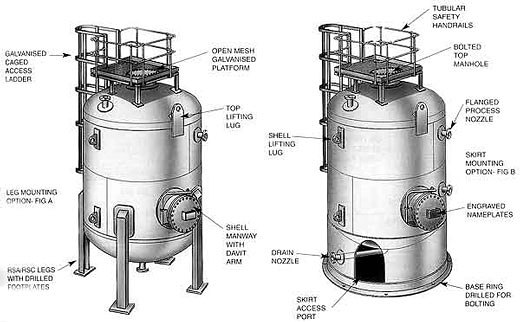

Pressure vessels are built to withstand intense internal or external pressure. This requires:

- Thick walls

- Reinforced seams and nozzles

- Seamless welding

- Rounded geometries to distribute pressure evenly

These principles are explored further in our resource on safety and compliance in pressure vessel design.

In contrast, water tanks are designed for static storage. Water tanks:

- Have thinner walls

- May be rectangular or cylindrical

- Focus on capacity rather than mechanical stress

- Are not rated for high pressure

Materials and Construction Standards

Pressure vessels are commonly fabricated from carbon steel, stainless steel, or specialty alloys. Learn how material selection matters in our guide to choosing the right material for pressure vessel fabrication.

Water tanks are often made from plastic, fiberglass, or basic metals and do not require ASME certification. For more on fabrication fundamentals, visit our metal fabrication overview and guide to metal fabrication.

Safety and Regulation

Because of the risk involved, pressure vessels are highly regulated. When considering pressure vessels vs. water tanks, the regulatory requirements differ significantly. Pressure vessels may require:

- Design approval by certified engineers

- Routine inspections by licensed professionals

- Nameplates identifying pressure ratings and design standards

For more detail, see our comprehensive guide to pressure vessel inspection and quality assurance in custom pressure tank manufacturing.

Water tanks generally face fewer regulatory requirements unless used for potable water or fire protection systems.

Which One Do You Need?

Choosing between pressure vessels vs. water tanks depends on your operating conditions. Ask yourself:

- Will the fluid be under pressure?

- Is consistent pressure critical?

- Are hazardous materials involved?

- What are the temperature and flow demands?

For deeper context, explore the purpose of a pressure vessel and water presence considerations in pressure vessels.

Use Case Scenarios

- Rainwater collection: Water tank

- Reverse osmosis system: Pressure vessel

- Gravity-fed irrigation: Water tank

- Refinery gas separation: Pressure vessel

Advanced Applications and Integrated Solutions

For complex industrial applications, the choice between pressure vessels vs. water tanks often extends beyond simple storage needs. Many projects require integrated solutions that combine multiple components for optimal performance.

Consider modular skids that may incorporate both pressure vessels and water tanks in a single, pre-engineered system. These solutions are particularly valuable in:

- Chemical processing plants

- Water treatment facilities

- Oil and gas operations

Our prefabrication services can integrate pressure vessels or water tanks into larger systems, reducing on-site installation time and ensuring quality control.

Pressure Vessels vs. Water Tanks: Making the Right Choice for Safe and Efficient Fluid Storage

The decision between pressure vessels vs. water tanks ultimately comes down to matching engineering solutions to operational needs. Choose pressure vessels for high-pressure applications requiring ASME compliance, or water tanks for atmospheric storage. Red River’s expertise ensures optimal safety, performance, and regulatory compliance for your specific requirements.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today through our contact page and experience the Red River difference. Where American-made products and American Values come together, we care more. For immediate assistance with your project requirements, request a quote today.

Frequently Asked Questions (FAQ)

1. Can a water tank be used as a pressure vessel?

No. Water tanks aren’t built to withstand internal pressure and can fail under such conditions that pressure vessels are designed to handle. This is a key distinction in pressure vessels vs. water tanks.

2. What materials are pressure vessels usually made from?

Pressure vessels are typically made from stainless steel, carbon steel, and other high-strength alloys that meet ASME standards. Learn more about our metal fabrications capabilities.

3. Do pressure vessels require certification?

Yes. Most pressure vessels must be designed, tested, and certified according to ASME standards, which is a major difference in pressure vessels vs. water tanks.

4. Are water tanks cheaper than pressure vessels?

Typically, yes water tanks are cheaper than pressure vessels due to less stringent materials and structural requirements.

5. How often should pressure vessels be inspected?

Pressure vessels should be inspected regularly depending on usage and regulation. Annual checks are common for pressure vessels in industrial settings.

6. What industries rely heavily on pressure vessels?

Oil and gas, chemical manufacturing, energy production, and water treatment facilities rely heavily on pressure vessels.

7. Can fiberglass be used for pressure vessels?

Rarely. Fiberglass is more common for water tanks due to lower pressure needs, while pressure vessels require stronger materials another key point in pressure vessels vs. water tanks.

8. Is ASME certification required for all pressure vessels?

It depends on jurisdiction and application, but ASME certification is widely recommended for industrial pressure vessels.

Key Takeaways

- Pressure vessels are engineered to store and handle fluids or gases under high pressure

- Water tanks are designed for atmospheric or low-pressure fluid storage

- Choosing incorrectly in pressure vessels vs. water tanks can lead to system failure, safety risks, or regulatory issues

- Material strength, certification requirements, and structural integrity set pressure vessels vs. water tanks apart

- Red River has decades of experience designing and fabricating custom pressure vessels that meet the highest industry standards

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No related articles found.

About Author