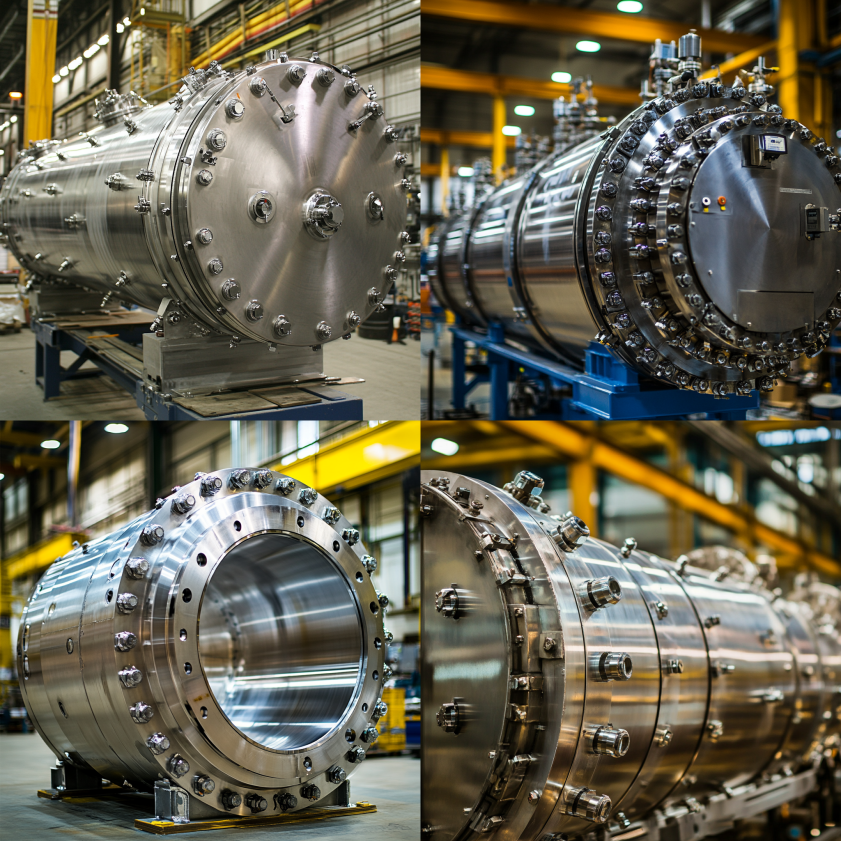

Custom pressure vessels are purpose-built to match exact process, space, and safety requirements, delivering better performance, compliance, and long-term value than standard equipment across demanding industries. Red River designs flexible, application-specific pressure vessels and modular systems that improve efficiency, safety, and reliability while reducing lifetime costs.

Meeting Industrial Challenges with Tailored Solutions

In today’s dynamic industrial landscape, one-size-fits-all equipment often doesn’t make the cut. Every process has its nuances, different inputs, outputs, space constraints, safety standards, and performance goals. This is where custom pressure vessels step in as essential tools for tailoring process equipment to exact specifications. With thoughtful engineering and flexibility in design, custom pressure vessels deliver exceptional value, safety, and performance across diverse industrial sectors.

At Red River, we understand that custom pressure vessels don’t mean complicated; they mean practical, optimized, and built with purpose. With deep experience across pressure vessel fabrication, modular skids, and prefabrication, our team designs solutions that align with real-world operational needs.

This blog explores how flexible custom pressure vessel design addresses unique industrial challenges and why more industries are investing in tailored solutions.

Why Flexibility Matters in Industrial Pressure Vessel Design

Industrial processes vary widely from high-pressure steam in power plants to corrosive chemical mixtures in pharmaceutical labs. The equipment supporting these processes needs to align with the precise conditions under which it operates. Design flexibility in custom pressure vessels offers industries the ability to:

- Meet exact process requirements

- Operate safely under challenging conditions

- Fit into limited or uniquely shaped spaces

- Stay compliant with regulatory demands

For example, a water treatment facility exposed to aggressive chemicals and saltwater environments benefits significantly from vessels designed with corrosion resistance in mind. Learn more about how water systems rely on pressure vessels in Understanding Water Tanks as Pressure Vessels.

Rather than forcing operations to adapt to equipment, custom pressure vessels are engineered to fit the facility blueprint, a principle reinforced throughout Red River’s solutions portfolio.

Industries that typically benefit from custom pressure vessels include:

- Oil & Gas

- Chemical and Petrochemical

- Water Treatment

- Food and Beverage

- Pharmaceutical and Biotech

- Power Generation

Each of these sectors faces demanding conditions, temperature extremes, pressure differentials, and corrosive environments, making flexible pressure vessel design a necessity, not a luxury. For power-specific insights, see Pressure Vessels in the Power Generation Industry.

Key Design Factors that Enable Customization

Materials and Coatings

Material selection plays a critical role in pressure vessel performance and longevity. Red River engineers carefully evaluate operating conditions using best practices outlined in Choosing the Right Material for Pressure Vessel Fabrication.

Common materials for custom pressure vessels include:

Carbon Steel: Economical and durable for general use in custom pressure vessels

Stainless Steel: Resistant to corrosion and contamination in custom pressure vessels

Specialty Alloys: For high-temperature or highly corrosive applications in custom pressure vessels

Protective coatings such as epoxy linings or PTFE finishes further extend vessel life, aligning with corrosion mitigation strategies discussed in Safety and Compliance in Pressure Vessel Design.

The choice of material and coating for custom pressure vessels must align with:

- Operating pressure and temperature

- Nature of the contents (e.g., acidic, flammable, food-grade)

- Environmental conditions (indoor vs. outdoor)

Dimensions, Volume, and Orientation

Every facility has its own layout. Some plants have abundant vertical space, while others have only horizontal clearance. The dimensions and orientation of custom pressure vessels must adapt accordingly. Custom pressure vessels allow for:

- Varying diameters and heights to suit spatial constraints

- Horizontal or vertical orientations

- Specialized internal geometry to promote flow, separation, or reaction

This adaptability is especially valuable in offshore or skid-mounted systems. Learn more about skid integration in Modular Skid Systems and how vessels fit seamlessly into compact layouts.

Nozzles, Ports, and Internal Components

Nozzles and ports in custom pressure vessels are more than just access points they play a crucial role in process control, maintenance, and safety. Custom pressure vessel designs allow:

- Placement of nozzles exactly where needed

- Inclusion of manways for inspection and cleaning

- Integration of internal components like baffles, diffusers, trays, or coils

These features enhance efficiency and align with fabrication best practices described in The Fabrication Process: Cutting, Folding, Welding.

Real-World Applications and Use Cases

Let’s consider a few examples where custom pressure vessel design has made a measurable difference:

Case 1: Modular Skid Systems for Oil Refining

A major oil refiner required compact, transportable vessels integrated into modular skid packages. By leveraging prefabrication capabilities and advanced layout planning, Red River delivered vessels that reduced installation time and increased deployment flexibility.

Case 2: Compact Layout for Food Processing

In a food-grade facility with low ceiling clearance and strict sanitation standards, standard designs weren’t viable. Red River engineered horizontal stainless steel vessels with hygienic finishes, aligning with insights from Why Use Stainless Steel Sheet Metal Fabrication.

Case 3: Water Treatment in Corrosive Environments

In coastal water treatment plants, salt and humidity take a toll on metal. Red River fabricated custom pressure vessels using duplex stainless steel with specialized coatings for added protection. Our team also included integrated pressure relief systems and smart sensor compatibility for remote monitoring in these custom pressure vessels, ensuring long-term reliability.

Each case emphasizes the importance of custom pressure vessel design tailored to operational reality ,not theoretical generalizations.

Benefits of Custom Pressure Vessels

Optimized Performance

When custom pressure vessels are designed around your specific processes, they perform better. Period. Custom pressure vessels:

- Operate efficiently within defined parameters

- Handle specific chemical or physical interactions

- Integrate seamlessly with existing infrastructure

For foundational understanding, explore Understanding the Purpose of a Pressure Vessel.

Improved Safety and Compliance

Custom vessels meet or exceed safety standards, including:

- ASME Section VIII, Div. 1 & 2

- API codes

- FDA and 3-A Sanitary Standards for food and pharma

- NACE standards for corrosion-resistant design

With custom features like pressure relief devices, burst discs, and integrated sensors, plant operators enjoy enhanced peace of mind.

To stay updated on inspection and safety best practices, check out OSHA’s pressure vessel safety guidelines.

Cost-Efficiency Over Time

Although initial investment in custom pressure vessels might be higher, custom pressure vessels reduce costs long-term by:

- Minimizing downtime due to unplanned maintenance

- Avoiding retrofits or spatial adjustments

- Prolonging vessel lifespan with materials tailored to the application

It’s a value-forward decision, especially in high-risk industries utilizing custom pressure vessels.

Why Custom Pressure Vessels Are the Right Long-Term Solution

Custom pressure vessels play a critical role in helping industries overcome complex operational, spatial, and safety challenges by delivering equipment engineered specifically for real-world conditions. By tailoring materials, dimensions, internal components, and compliance features to each application, custom pressure vessels provide superior performance, enhanced safety, and long-term cost efficiency that standardized equipment simply cannot match.

As industries continue to demand higher reliability and efficiency, partnering with an experienced manufacturer like Red River ensures custom pressure vessels are designed, fabricated, and delivered with purpose, supporting sustainable operations, regulatory confidence, and measurable return on investment well into the future.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions (FAQ)

1. What makes a pressure vessel “custom”?

A custom pressure vessel is purpose-built for a specific process. This includes custom dimensions, material selection, pressure ratings, nozzle configurations, and more.

2. Are custom vessels more expensive than standard ones?

While custom vessels typically have a higher upfront cost, they often result in lower lifetime costs due to improved efficiency and reduced maintenance.

3. Which industries benefit most from custom pressure vessels?

Industries with stringent operational, space, or safety requirements, such as chemical processing, pharmaceuticals, and oil & gas gain the most from custom designs.

4. What codes and standards apply to custom vessels?

Designs generally follow ASME Section VIII standards, but may also adhere to API, NACE, or industry-specific safety and hygiene requirements.

5. Can I customize both internal and external features?

Yes. Internal features like baffles, coils, or liners, and external features such as supports, jackets, and ports can be fully customized.

6. How long does it take to fabricate a custom pressure vessel?

Fabrication timelines vary by complexity but generally range from 6 to 16 weeks, including design, materials sourcing, fabrication, and testing.

7. Do I need a modular design for my custom vessel?

If you’re working in remote, mobile, or temporary locations, modular skid packages offer the convenience of rapid deployment and compact integration.

8. How do I start the custom design process?

Contact an experienced manufacturer like Red River, who can walk you through a tailored consultation process, from spec development to delivery.

Key Takeaways

- Custom pressure vessels provide unmatched flexibility across design, materials, and application

- Industries like oil & gas, water treatment, and food processing rely on custom pressure vessels to meet their unique challenges

- Key design elements for custom pressure vessels include material selection, orientation, internal components, and port placement

- The long-term ROI of custom pressure vessels includes performance, safety, and cost-efficiency

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No related articles found.