Understanding Coalescing is essential in many industries where separating small particles or droplets from fluids or gases ensures operational efficiency and product quality. This process improves filtration, enhances performance, and extends equipment lifespan. At Red River, we provide advanced coalescing solutions designed for durability and optimal performance. Incorporating these methods helps industries maintain compliance with Pressure Vessel Safety Standards and Compliance and reduce downtime. Coalescing is a practical, cost-effective solution for improving production processes and safeguarding equipment.

What is Coalescing?

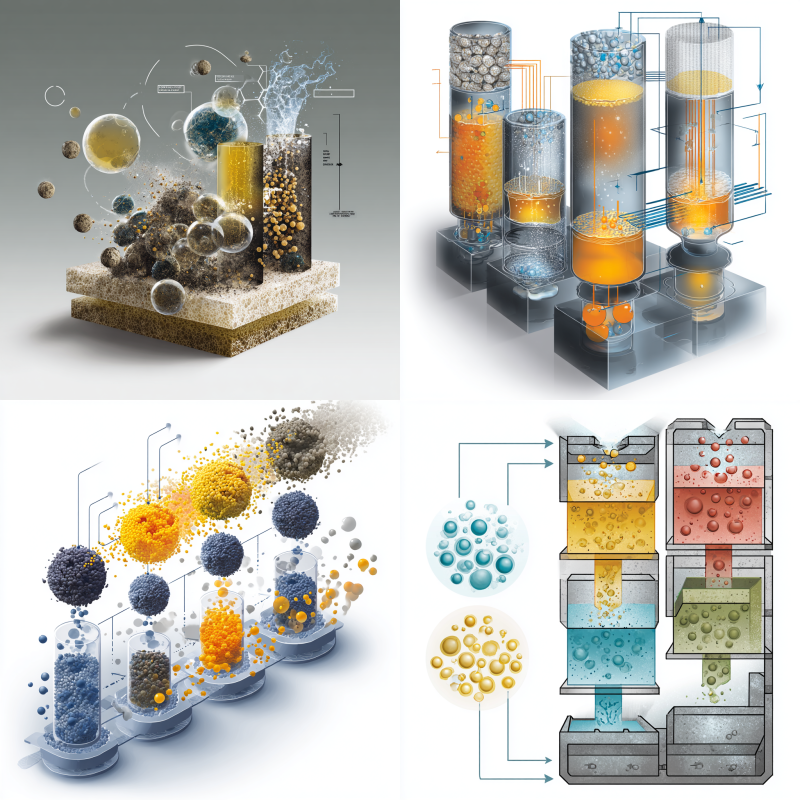

Coalescing is an important method in numerous industries, together with manufacturing, in which small particles merge to form a larger entity. This approach is critical in applications like filtration, in which isolating debris from liquids or gases is vital for producing amazing outputs. At Red River, we recognize the importance of coalescing to ensure the overall performance and reliability of your systems.

Key Characteristics of Coalescing

When we talk about coalescing, we’re referring to the functionality to combine particles through a bodily or chemical approach. The key tendencies of coalescing include:

- Efficiency: The manner is as a substitute green in separating high-quality particles from fluids.

- Versatility: It may be executed for the duration of wonderful mediums, whether or not or no longer liquid or gas.

- Effectiveness: Coalescing complements the first-class of the final product with the aid of doing away with contaminants.

Understanding the one’s tendencies lets in in selecting the right coalescing strategies in your precise needs.

Common Misconceptions About Coalescing

Some misconceptions about coalescing need to be addressed:

Coalescing is best for huge-scale operations: In truth, coalescing is beneficial for both small and huge-scale operations.

- It’s a complex manner: While it includes today’s generation, the fundamental principles are honest and can be effortlessly covered in current systems.

- Coalescing filters need commonplace replacement: High-quality coalescing filters, just like the ones we manufacture at Red River, are designed for durability and long-term use.

At Red River, we delight ourselves in supplying complete solutions that encompass contemporary coalescing strategies. Our dedication to American values, quality, and protection ensures that you obtain high-quality feasible issuers and products. When you partner with us, you get direct access to organization specialists like Reilly Sasse, who brings a wealth of information and a dedication to meeting your unique desires.

The Coalescing Process Explained

How Coalescing Works

Coalescing is a device in which small droplets or particles merge to form large ones, that can then be extra effortlessly separated from a combination. This is in particular useful in filtration structures. In an average coalescing filter out, a medium captures first-rate particles or droplets. As these particles accumulate, they combine to shape big clusters. Gravity or unique forces then separate those large clusters from the fluid. This affects a cleanser, or purer prevention product, whether or not or no longer it is air, water, or another liquid.

Industrial Applications of Coalescing

The coalescing method is critical in numerous commercial packages. In the oil and gasoline industry, it’s used to eliminate water and particulate depend from hydrocarbons, ensuring the purity and fantastic of the product. In the energy era, coalescing filters assist hold the overall performance and durability of generators with the resource of filtering out contaminants. The manner is also critical in manufacturing sectors, together with prescribed drugs and meal processing, wherein purity and cleanliness are paramount. By integrating coalescing generation, those industries achieve higher operational performance and product great.

Examples of Coalescing in Action

At Red River, we’ve effectively applied coalescing solutions throughout several initiatives. For instance, our coalescing filters were used in herbal fuel processing to remove moisture and particulates, notably enhancing the first-rate of output. In a few other challenges, our coalescing structures have been instrumental in a strength plant, enhancing the general performance and lifespan in their turbines by way of ensuring the air coming into the system turned into contaminant-unfastened. These examples show how coalescing can bring about tangible enhancements in industrial operations.

Benefits of Coalescing in Manufacturing

Efficiency Improvements

Coalescing drastically boosts overall performance in production procedures. By efficaciously keeping apart contaminants from fluids, coalescing reduces the wear and tear and tear on the device, minimizing downtime for protection and preservation. This ends in a more streamlined operation, bearing in mind non-stop manufacturing without commonplace interruptions. For instance, within the oil and gasoline agency, coalescing filters do away with water and particulates from hydrocarbons, making sure smoother and extra green processing.

Cost-Effectiveness

Implementing coalescing strategies can result in great price financial savings. By improving the lifespan of equipment and decreasing the need for common filter-out replacements, businesses can lower their operational fees. Additionally, advanced efficiency manner much less power intake, translating to lower application payments. At Red River, we recognize that each dollar counts, and our coalescing solutions are designed to offer maximum move return on funding through the use of minimizing waste and optimizing resource use.

Enhancing Product Quality

One of the most huge blessings of coalescing is the enhancement of product wonderful. In industries like pharmaceuticals and food processing, in which purity is important, coalescing ensures that final products are unfastened from contaminants. This leads to better customer pride and compliance with stringent enterprise necessities. By removing impurities, coalescing no longer handiest improves the aesthetic excellent of merchandise but additionally their overall performance and protection.

Choosing the Right Coalescing Equipment

Factors to Consider

When selecting a coalescing system, several elements must be taken into consideration to ensure maximum fulfilling normal performance. First, perceive the particular contaminants you need to put off, whether or not or no longer they’ll be particulates, water droplets, or different impurities. The float rate of your system is every different crucial detail because it determines the capacity and period of the coalescing cleanout required. Additionally, do not forget the going-for-wal conditions, which consist of temperature and pressure, as these will have an effect on the filter out’s performance and lifespan. Material compatibility is likewise essential, ensuring that the clear-out media can face up to the fluids and contaminants it’ll stumble upon.

Comparing Coalescing Filters

Not all coalescing filters are created equal. When evaluating options, take a look at the filtration efficiency, which indicates the proportion of contaminants the clear-out can remove. Pore length is a few different essential metrics, with smaller pores generally providing better filtration but potentially decreasing glide rates. Durability and sturdiness are also key issues; tremendous filters may have a better upfront price but can save money in the end requiring much less common replacements. At Red River, we provide a variety of coalescing filters designed to meet numerous business needs, ensuring you get the first-rate performance and price.

Maintenance and Care

Proper protection is important for the toughness and effectiveness of the coalescing device. Regularly test out filters for signs of clogging or damage and replace them as had to save you a drop in general overall performance. Keep an eye on pressure differentials, as a stunning increase can mean a clogged clear out of that goal’s interest. Routine cleaning of the tool also can assist in maintaining maximum dependable operation. At Red River, we provide comprehensive upkeep suggestions and assist in ensuring your coalescing machine stays in a pinnacle situation, turning in dependable and green overall performance.

Understanding Coalescing

Understanding Coalescing is vital for maintaining operational efficiency, product quality, and equipment safety. Coalescing improves separation processes, reduces maintenance, and supports compliance with Pressure Vessel Safety Standards and Compliance. Red River’s expertise in designing high-quality coalescing solutions ensures industries achieve reliable, long-lasting results. By integrating advanced filtration technology, clients benefit from increased performance, reduced costs, and safer operations.

Partner With Experts in Coalescing Solutions

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions (FAQ)

1. What industries benefit most from coalescing technology?

Industries requiring purity and separation, including oil and gas, food and beverage, pharmaceuticals, energy generation, and chemical production, benefit significantly from coalescing.

2. How do I choose the right coalescing filter for my application?

Consider contaminant type, flow rate, operating conditions, and material compatibility. Expert consultation ensures the filter meets your specific operational needs.

3. What maintenance practices are essential for coalescing filters?

Regular inspections, monitoring pressure differentials, routine cleaning, and adherence to manufacturer guidelines maintain performance and prolong lifespan.

4. Can coalescing filters handle all types of liquids and gases?

Yes, coalescing filters are versatile and can separate contaminants from both liquids and gases, including fuels, oils, natural gas, and compressed air.

5. What advancements are being made in coalescing technology?

Innovations focus on higher filtration efficiency, durability, sustainability, and real-time diagnostics for monitoring and maintenance scheduling.

6. How does coalescing impact equipment performance?

Coalescing protects equipment from wear and contamination, reduces downtime, and enhances overall system reliability and lifespan.

Key Takeaways

- Understanding Coalescing improves separation, efficiency, and product quality.

- Industrial applications include oil and gas, energy, pharmaceuticals, and food processing.

- Proper selection and maintenance of filters ensure optimal performance and longevity.

- Coalescing supports compliance with ASME code for pressure vessel safety and inspection standards.

- Red River provides durable, high-performance coalescing solutions tailored to industry needs.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

- Introduction to Coalescing Filters

- How to Change and Maintain Coalescing Filter for Oil Systems

- Understanding Coalescing Oil Separators

- Desiccant Filters vs. Coalescing Filters: How to Choose the Right Filtration Method

- The Importance of Filtration in Industrial Applications

- Coalescing Filter Lifespan: How Long Does It Last?

About Author