Performing fatigue failure analysis involves gathering operational and material data, using methods like visual inspection, nondestructive testing, fractography, and computational tools such as S-N curves and finite element analysis. Identifying fatigue triggers like cyclic loading, environmental factors, and design flaws helps prevent crack growth. Combining thorough inspection schedules, quality materials, and advanced modeling ensures safer, longer-lasting industrial components.

Mastering How to Perform Fatigue Failure Analysis

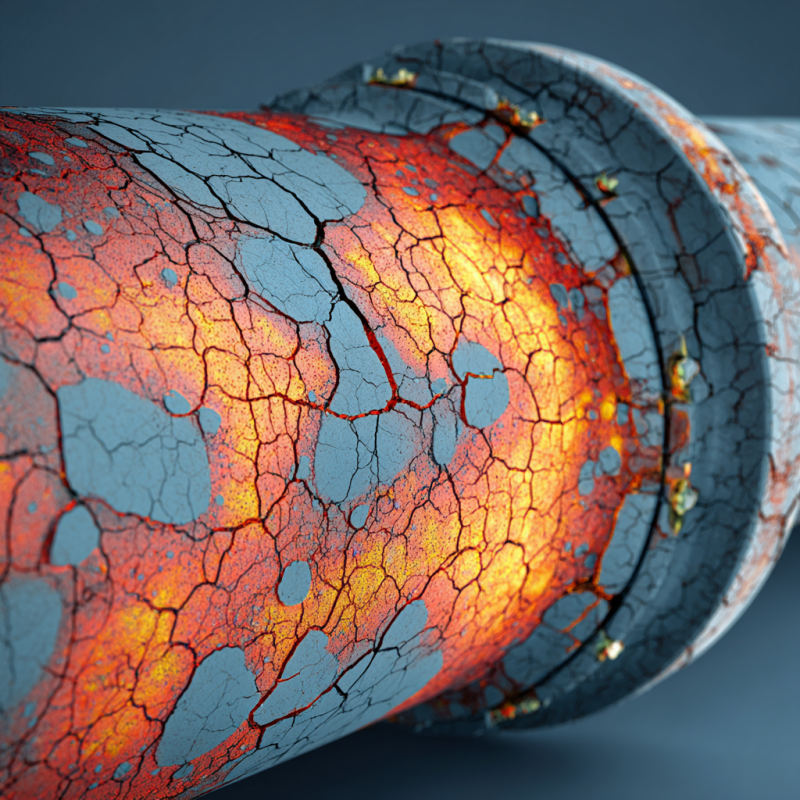

Fatigue failure is often cited as a major cause of mechanical breakdown in heavy industries, with some estimates suggesting it contributes to more than half of all metal failures. If you want to know how to perform fatigue failure analysis with confidence, you are in the right place. By zeroing in on cyclical stresses, material properties, and the influence of the operating environment, you can spot early warning signs before they become critical. Below, you will learn essential techniques to streamline your approach, reduce risk, and extend the life of pressure vessels and other core systems.

How to Perform Fatigue Failure Analysis

Fatigue failure generally occurs when cyclic loads weaken a component over time. It is a progressive process, meaning a crack can begin microscopically and grow under repeated stress cycles. While this phenomenon appears complex, following a clear method makes each step more manageable:

Gather Operational Data

- Identify stress patterns: Begin by documenting load cycles, operating temperature, and any environmental factors (like moisture or corrosive chemicals) so you have a baseline for how the part or vessel is used day-to-day.

- Determine material specs: Check the material’s composition, heat treatment history, and mechanical properties. If the part is part of a larger system such as a pressure vessel, note any relevant design codes like ASME.

- Collect service records: Maintenance logs, repair notes, and prior inspection data help you track how a component has aged and what events might have initiated cracks or other signs of weakness.

Pick the Correct Approach

- Visual inspection: Start with a close look for cracks, discoloration, or surface anomalies. Even hairline cracks can reveal ongoing fatigue.

- Nondestructive testing (NDT): Techniques such as ultrasonic or magnetic particle inspection help uncover subsurface cracks. They are useful for detailed examinations without damaging the component.

- Fractography: If you do find a fracture or crack, microscopic analysis of the fracture surface (fractography) helps you confirm whether fatigue, overload, or another mechanism caused the issue.

Use Analytical Tools

- Stress-life (S-N) method: Common for predicting the number of cycles a material can withstand before failure. Engineers rely on S-N curves to gauge component fatigue life under different load levels.

- Fracture mechanics approach: Ideal for advanced evaluation of an existing crack’s growth rate. You track how quickly a tiny crack will propagate under repeated loads.

- Finite element analysis (FEA): FEA software simulates stress distribution across complex shapes. It is especially handy for intricate pressure vessel designs and skid packages where geometry and interactions can be complex.

If you want to see how these methods fit into broader investigations of mechanical breakdown, you may find material failure analysis a helpful starting point.

Recognize Main Fatigue Triggers

Knowing why fatigue emerges is half the battle. When you recognize the triggers, you can correct them before they do serious damage:

- Cyclic loading: Stress changes within each operational cycle can cause micro-cracks to appear and expand. For instance, repeated pressurization in pressure vessels is a major driver.

- Environmental conditions: Corrosion can speed up crack growth if materials are exposed to moisture, acids, or other harsh chemicals. For deeper insight into environmental damage, consider corrosion failure analysis.

- Design flaws: Sharp corners, weld misalignments, or under-designed components concentrate stress in a small area. These flaws act like a focal point for fatigue damage.

- Operational changes: A system that was originally designed for steady loads might be pushed to handle regular starts and stops. Each shift in load intensifies wear on the material.

If you want to delve into other causes of breakdown in vessels, you can also explore what causes pressure vessel failure.

Evaluate Advanced Testing Techniques

Basic inspections alone might not always reveal subtle signs of fatigue. That is where more advanced strategies come in:

Strain Gauging and Sensors

Attaching strain gauges or sensors to critical points lets you watch stress levels in real time. If you detect stress spikes that exceed the material’s safe threshold, you can intervene before micro-cracks form.

Spectral Analysis

Periodic monitoring of vibration data can show changes linked to damage progression. An unusual shift in a vibration signature may hint that a crack is forming. This technique is especially useful in rotating machinery.

Specialized Software Modeling

Companies such as Red River LLC use modeling tools that integrate design data, load conditions, and failure criteria for pressure vessel manufacturing. By simulating thousands of cycles digitally, they spot potential weak spots before production, saving time and money. If you handle modular process equipment, this type of digital modeling can rapidly highlight areas of concern and guide design improvements.

Implement Best Practices for Prevention

A reliable fatigue failure analysis process often points to helpful preventative measures. Here are practical, proven fixes:

- Eliminate stress risers: Tweak the design to remove sharp corners and abrupt changes in cross-sections. Keep welds smooth to reduce peak stress.

- Use quality materials: Alloys with good fatigue performance (like high-strength steels or treated aluminum) have a longer life under repeated loads. Make sure suppliers track full material traceability, a key step that Red River LLC emphasizes.

- Apply surface treatments: Processes like shot peening or surface hardening can stall crack formation by introducing compressive stresses on the surface.

- Schedule regular inspections: Monitor critical components, especially welds and joints, to catch cracks early. Pair visual checks with nondestructive tests for best results.

- Lean into prefabrication: Prefabricated assemblies, such as those from Red River LLC, are made in controlled shop environments. This consistency reduces onsite variability, lowers error rates, and decreases the likelihood of fatigue-inducing defects.

You can deepen your understanding of systematic reviews by checking out pressure vessel failure analysis or exploring specialized guides like fatigue failure analysis.

Review How to Perform Fatigue Failure Analysis

Let us recap your process:

- Gather load, material, and service data.

- Choose the right evaluation method.

- Apply S-N curves, fracture mechanics, or FEA tools.

- Use results to redesign, upgrade materials, or improve inspections.

By staying alert to cyclical loads and environmental conditions, you will reduce unexpected breakdowns and protect critical industrial systems.

Take Action: Master Fatigue Failure Analysis Today

If you want to safeguard your operations and reduce costly downtime, now is the time to apply these fatigue failure analysis techniques. Get expert guidance from trusted professionals to ensure your systems last longer and perform better.

Frequently Asked Questions

1. What is fatigue failure analysis

Fatigue failure analysis is the process of examining materials or components that have fractured due to repeated or cyclic stress over time. It identifies the causes, mechanisms, and contributing factors of fatigue to prevent future failures.

2. Why is fatigue failure analysis important

Fatigue failure analysis is important because it helps prevent unexpected breakdowns in structures or machinery, improves safety, and guides better material selection and design to extend service life.

3. What if I already found a micro-crack?

You should measure its size and track its growth rate. Use fracture mechanics to estimate how many load cycles remain before reaching a critical crack length.

4. Do I need special software for analysis?

Not always, but specialized software like finite element analysis (FEA) is invaluable for complex geometries or high-stakes applications. Manual calculations can work for simpler cases.

5. Can fatigue occur in non-metal materials?

Yes, polymers and composites can also fail due to repeated loads. They have distinct properties, so their analysis may require different data and testing methods.

Key Takeaways

- Collect all relevant data, including stress loads, material properties, and service history.

- Employ appropriate techniques such as NDT, fractography, or FEA to pinpoint early-stage fatigue.

- Look out for environmental influences like corrosion or temperature swings that may speed up crack growth.

- Remove design flaws (weld misalignments, sharp corners) and use suitable materials to reduce fatigue risk.

- Create an ongoing inspection schedule, combine it with thorough documentation, and maintain a proactive mindset.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author