Industrial fuel water separator vessels remove water and contaminants from fuel, ensuring safety, preventing corrosion, and extending equipment life. They are vital in energy, chemical, and manufacturing industries.

Understanding Why Are Industrial Fuel Water Separator Vessels Important

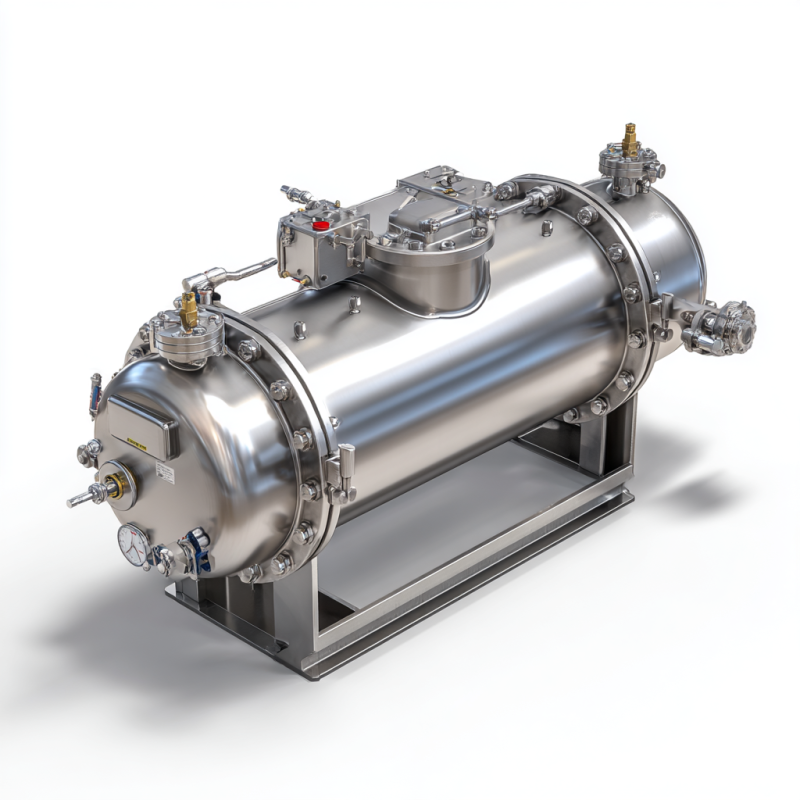

Imagine working in an environment where even a drop of water in a fuel line can lead to corrosion, engine stalls, and costly downtime. Good news, though, this is easier to fix than it sounds. Industrial fuel water separator vessels are designed to remove water and particulates from fuel, among other fluids, so you can keep systems running with fewer interruptions and safer operations. You will often find these vessels in energy production, agriculture, chemical processing, and more. So why are industrial fuel water separator vessels important? Let us take a closer look at how they work, the advantages of modular approaches, and how you can enhance safety and efficiency without adding extra headaches.

Why Are Industrial Fuel Water Separator Vessels Important

When fuel contains too much water, you may end up with rust in storage tanks or compromised engines that need more frequent maintenance. These separator vessels help you avoid those problems by removing water and other contaminants from your fuel stream before any serious damage occurs. In the oil and gas sector, water often appears alongside hydrocarbons that must be separated to maintain the correct balance for refining processes. According to Red River, industries that rely on pressure vessels, such as fuel water separators, can save on maintenance and minimize risk by installing properly designed units right from the start.

Another critical reason these vessels matter is the safety component. Flammable liquids must be handled with great care, and water in fuel can result in sudden temperature changes, freezing issues in cold climates, or incomplete combustion that leads to higher emissions. By incorporating a well-built industrial fuel water separator vessel into your process, you shield your operation from avoidable breakdowns and unsafe working conditions.

Key Functions of Fuel Water Separator Vessels

A fuel water separator vessel might seem simple at first glance. However, these vessels perform several behind-the-scenes actions to protect your equipment:

- Remove water from fuel: Their primary function is separating water droplets from the main fuel flow. Particles are directed through a combination of filtration and centrifugal force, forcing denser water molecules to settle out of the fluid stream.

- Eliminate particulate contaminants: Dirt, rust flakes, and other solid materials can harm delicate machinery if not filtered out. These vessels often include filter cartridges that trap or repel such particles.

- Ensure clean fuel flow: By controlling water and solids, separators help maintain the ideal fuel mixture for downstream processes and engines, leading to more consistent performance and fewer outages.

- Protect equipment life: Engines, turbines, and pumps operate more efficiently when they are not clogged or corroded by contaminated fuels. A dedicated separator vessel can extend the life of these components.

If your system relies on diesel or other fuels, you might also explore a diesel pressure vessel filter separator to see how it compares and complements your current setup. For many industrial sites, these solutions become part of an overall safety and performance strategy.

Safety Gains From Proper Separation

Water-contaminated fuel is not just an inconvenience; it can be hazardous. Excess moisture fosters bacterial growth (leading to sludge) and promotes corrosion that wears away metal components from the inside. Over time, this can weaken key parts that must handle intense pressures. By using a robust separator vessel, you guard against leaks and potential safety failures that might force an unplanned shutdown or, worse, lead to accidents.

In large-scale operations, especially in oil and gas refineries, multiphase separators deal with complex fluid streams where water, gases, and oil intermingle. According to Red River, prefabricating these separator vessels in controlled settings can further boost safety by reducing on-site welding and assembly time. Fewer exposure hours on the job site can translate into lower insurance rates and less risk for your team. Mixing in advanced software modeling to identify design conflicts ahead of time means that once your vessel arrives on-site, it is nearly ready to go.

Modular Solutions for Better Efficiency

Modular solutions are often overlooked. Yet these prefabricated skids and assemblies can be a game-changer if you are juggling tight spaces, strict timelines, and safety rules:

- Shorter construction time: Prefabrication can sidestep weather delays that typically slow down on-site builds, letting you invest more time in actual production rather than waiting to finish structural work.

- Reduced costs: With fewer onsite man-hours, you lower labor expenses and cut exposure to safety incidents. Additionally, shipping complete modules can minimize costly transport overhead.

- Quality control in a controlled environment: Modular components, including industrial fuel water separator vessels, are often fabricated in a specialized facility. This controlled approach can reduce errors and enhance final product quality.

- Scalability: If you need extra capacity later, adding another prefabricated unit is relatively simple. This modular philosophy keeps your expansion timeline more predictable.

For more effective control of water contaminants, some facilities also use a fuel water separator attached to a skid for convenient installation. A single packaged unit that includes pumps, filters, and instrumentation can significantly compress your overall project schedule.

Why Are Industrial Fuel Water Separator Vessels Important for Safety

These vessels are not just helpful add-ons to your facility, they are a linchpin in maintaining safe, efficient operations. By filtering out water and particles, you protect your critical equipment from rust, blockages, and unplanned breakdowns. You also reduce safety risks, particularly in high-stakes environments like refineries and chemical plants. Pairing industrial fuel water separator vessels with modular fabrication amplifies these benefits by cutting installation time, boosting quality, and simplifying scalability. In short, when you want to keep your system running smoothly and your team safe, effective separation is the key.

Ensure Cleaner Fuel and Safer Operations Today

Partner with Red River to integrate industrial fuel water separator vessels into your facility. Improve efficiency, cut downtime, and protect your operations. Contact us today to get started.

Frequently Asked Questions

1. What is an industrial fuel water separator vessel?

An industrial fuel water separator vessel is a specialized container designed to remove water and other contaminants from fuels or industrial liquids. It ensures cleaner fuel for engines, turbines, or other equipment while meeting safety and operational standards.

2. How does an industrial fuel water separator vessel work?

It separates water and impurities from fuel using gravity, density differences, and internal components like baffles, coalescers, or demister pads. Water collects in a lower chamber while clean fuel flows to the outlet for safe use.

3. Do all industries need industrial fuel water separator vessels?

If an operation deals with fluids containing fuel or oil, these vessels can be extremely beneficial. They show up in manufacturing, energy production, agriculture, and more.

4. How often do these vessels require maintenance?

Maintenance schedules vary, but it is smart to perform routine checks at least monthly. Inspect filters, gaskets, and flow rates to ensure you do not miss potential red flags.

5. Is prefabrication always the better choice?

In many cases, yes. Prefabrication in a controlled environment can reduce on-site errors, save time, and help you identify design issues early through tools like BIM modeling.

Key Takeaways

- Installing a dedicated separator vessel dramatically reduces water-related engine or process failures.

- Prefabrication decreases onsite exposure hours, cutting down on workplace risks and insurance rates.

- Modular designs are especially helpful if you plan to expand capacity over time.

- Routine checks enable you to find and fix minor issues before they become full-blown shutdowns.

- Fuel water separators protect your equipment and your bottom line while raising your overall safety standard.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author