A gas turbine fuel water separator vessel removes water from fuel using gravity, coalescing filters, and drainage. This process protects turbines, boosts efficiency, and prevents costly downtime.

Understanding How Does a Gas Turbine Fuel Water Separator Vessel Work

Water in turbine fuel can cause corrosion, efficiency loss, and shutdowns. A gas turbine fuel water separator vessel removes water droplets from fuel to protect your turbine and improve performance. Experts at Red River design custom, prefabricated vessels to fit your flow rates, space, and reliability needs. With the right separator, you can extend equipment life and maintain stable power output.

This article explains the basic process of water removal, how prefabrication saves cost and time, and tips for choosing the right vessel for your setup. You’ll learn why a fuel water separator is essential for turbine health and how to tailor it to your operation.

How Does a Gas Turbine Fuel Water Separator Vessel Work

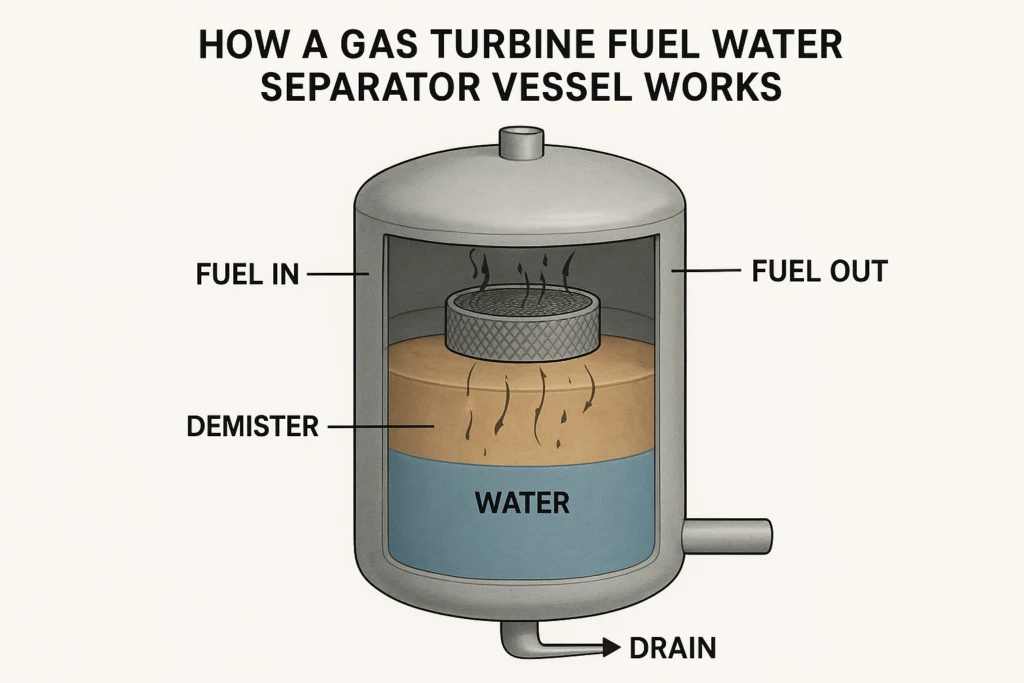

Fuel with water droplets or vapor enters the separator vessel under pressure. The vessel removes water through these main steps:

- Free-water knockout: Large water droplets settle by gravity as the vessel slows fuel flow.

- Coalescence: Smaller droplets combine into larger ones using coalescing filters, making them easier to separate.

- Separation and drainage: The heavier water droplets sink to the bottom and are drained out.

- Clean fuel outlet: Dry, clean fuel exits the vessel, ready for combustion.

This process handles different types of water contamination, improving fuel quality and reducing risks like corrosion, clogs, and downtime.

Explore Essential Components

Most fuel water separator vessels work on similar principles but include different filtering elements. Some even have built-in monitors to track water levels in real time. Key components include:

- Inlet diffuser or baffle: Distributes incoming fuel evenly and reduces turbulence.

- Coalescing media: Materials like fiberglass or polymers that help small water droplets combine.

- Filter cartridges: Remove fine particulates and very small water droplets.

- Water sump: Collects and drains water, preventing it from mixing back into the fuel.

- Monitoring gauges: Sensors or alarms that alert you to water levels or pressure changes.

Choosing the right components depends on your fuel type, turbine size, and operating conditions. If you use diesel backups, you may compare diesel vessel designs with gas turbine solutions. These vessels offer options to manage various flow rates and contamination levels.

Understand Prefabrication Steps

Prefabrication involves building and assembling modules in a controlled factory setting. This method has become popular because it reduces construction time and costs. According to Red River Solutions, working in a controlled environment helps avoid errors caused by weather or site limitations.

For a gas turbine fuel water separator vessel, prefabrication usually includes:

- Detailed design with modeling software: Engineers use tools like Building Information Modeling to spot conflicts before fabrication.

- Welding in a controlled environment: Skilled welders ensure high-quality, consistent welds with fewer interruptions, reducing risks and improving durability.

- Streamlined testing and inspection: Pressure tests and X-ray inspections happen under strict quality control, avoiding the need for complex field testing.

- Efficient shipping and on-site assembly: Completed modules are delivered just in time, reducing site clutter and speeding up the project timeline.

Using prefabrication saves time, money, and effort while reducing on-site labor and safety risks. This approach helps you meet deadlines and get your gas turbine running faster with less downtime.

See Typical Uses

Gas turbine fuel water separator vessels are vital in industries where reliable fuel quality is critical. Common applications include:

- Power generation: Ensures a stable, water-free fuel supply for consistent turbine combustion, reducing startup issues and stalls.

- Oil and gas: Removes water from fuel during exploration and transport to support high-temperature turbine operations.

- Chemicals and refining: Supports co-generation processes by preventing fuel moisture from disrupting chemical reactions.

- Large manufacturing complexes: Helps maximize turbine efficiency in combined heat and power systems with clean fuel.

If you want to explore other options, industrial fuel water separator vessels offer similar water removal solutions tailored to various environments.

Maintain Safety and Efficiency

You already know water can damage your turbine’s internal parts by promoting corrosion or incomplete combustion. But the effects on efficiency can be just as serious. Even a modest slump in combustion efficiency, if left unaddressed, can add up to significant operational costs over time. Some industry estimates suggest that equipment maintenance expenses can jump by 10 to 30% when fuel moisture is not controlled.

By keeping your fuel water content in check, you:

- Lower repair bill: Corroded parts and clogged filters need replacing more frequently if water is present.

- Protect your investment: Turbines are capital-intensive. Properly filtered fuel extends their lifetime and cuts the chances of unplanned failures.

- Improve fuel burn efficiency: Dry, contaminant-free fuel burns more evenly, maximizing the turbine’s power output per unit volume.

- Provide safer work environments: Less on-site intervention translates to fewer hazard possibilities. Prefabrication also reduces exposure risk by shortening the time workers spend at the jobsite.

According to a recent overview by Red River, prefabrication is not just about cost savings. It can also boost safety by minimizing on-site welding, which reduces open flames and lowers the risk of accidents.

Explore ASME Compliance and Design

Compliance with American Society of Mechanical Engineers (ASME) standards is essential for gas turbine fuel water separator vessels. These standards specify wall thickness, weld quality, and safe operating limits for temperature and pressure, ensuring a reliable and durable product.

Working with a trusted supplier typically involves:

- Preliminary design review: Assessing pressure, flow rate, and operating conditions to set vessel size and thickness.

- Material selection: Choosing high-grade steel or specialty alloys for corrosion resistance and strength.

- Welding certificates and inspection: Certified welders follow ASME Section VIII standards, with inspections verifying weld quality.

- Pressure testing: Hydrostatic or pneumatic tests confirm the vessel can safely handle pressures beyond normal use.

- Final documentation: Providing quality records including welder qualifications, test data, and compliance certificates.

To learn more about ASME pressure vessels used for fuel separation, resources like ASME pressure vessel separator offer detailed information. This ensures your separator performs reliably under varying temperature and pressure conditions.

Searching for the Right Vessel

Selecting the right separator vessel for your application involves more than just picking the right filters. Take a moment to consider:

- Operating pressure and temperature: Does your turbine run at high temperatures or face frequent spikes? Make sure the vessel materials can handle these conditions.

- Flow rate and fuel composition: The size and design of your vessel depend on how much fuel you push through hourly, as well as the contaminants present.

- Site-specific constraints: Do you have space restrictions? Will you need a vertical or horizontal separator? Also, clarify if you need any specialized safety features.

- Maintenance requirements: Some designs allow for easier filter changes and cleaning. Others require partial shutdowns and extra labor. Decide what suits your operational schedule best.

If your operations demand a specialized approach, you can look into a gas turbine fuel water separator vessel from providers like Red River, who can customize these systems to your exact process and site conditions.

How Does a Gas Turbine Fuel Water Separator Vessel Work to Improve Safety and Efficiency

Moisture-free fuel extends turbine life, reduces repair costs, and ensures safer work environments. With prefabrication and ASME compliance, you can trust in long-term reliability and efficient operation.

Take Action with Red River

Prevent corrosion, reduce downtime, and boost efficiency with a custom-designed, ASME-certified fuel water separator vessel. Prefabrication means faster installation and reliable performance tailored to your needs. Contact Red River to protect your investment and maximize uptime.

Frequently Asked Questions

1. What is a gas turbine fuel water separator vessel?

A gas turbine fuel water separator vessel is a device that removes water and contaminants from fuel before it reaches the turbine.

2. Why do gas turbines need fuel water separator vessels?

Gas turbines need them to prevent corrosion, blockages, and reduced efficiency caused by water or contaminants in the fuel.

3. Why does removing water matter so much?

Water can corrode metal parts, reduce combustion efficiency, and raise maintenance costs. Removing water means better turbine health and performance.

4. How do I know if my current filtration is enough?

Look for signs of rust or unexpected downtime. You might also do periodic fuel tests to measure water content. If your test results exceed manufacturer-recommended levels, consider a separator upgrade.

5. Can one vessel handle multiple fuel types?

In many cases, yes. However, you should always check the vessel’s design specs to make sure it is rated for your specific fuel and contamination levels.

Key Takeaway

- Effective moisture removal can extend the life of your gas turbine and reduce downtime.

- Prefabrication offers speed, cost savings, and consistent quality.

- ASME compliance ensures safe and reliable operation under a range of conditions.

- Custom-engineered options let you handle varying flow rates and contamination levels.

- Regular checks on filters and water levels keep efficiency high and costs down.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author