Pressure Vessel Design Basics

Pressure Vessel Design Basics are essential for anyone involved in industrial fabrication, mechanical engineering, or safety compliance. Understanding materials, stress analysis, and safety standards ensures reliable and compliant operations. Proper design protects both workers and equipment while maintaining regulatory adherence. This guide explores core principles, standards, and best practices for successful pressure vessel design.

Pressure Vessel Design Basics

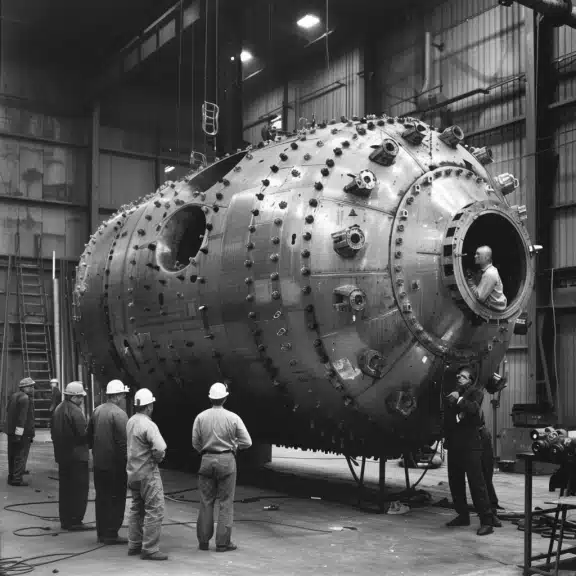

Understanding the basics of pressure vessel design is crucial for anyone involved in industrial fabrication, mechanical engineering, or safety compliance. These vessels are used to store or transport pressurized fluids across various sectors—from oil and gas to food processing—and their design must meet strict engineering and regulatory requirements.

Understanding What a Pressure Vessel Is

The basics of pressure vessel design start with understanding the core purpose of these vessels: to safely contain gases or liquids at pressures significantly different from the surrounding atmosphere. They must be engineered to handle both internal and external stress without failure.

Common industries that depend on pressure vessels include:

- Oil and Gas: Transporting hydrocarbons, gas storage, and separators

- Chemical Processing: Reactors and high-pressure tanks

- Power Generation: Steam drums, boilers, and heat exchangers

- Food & Pharma: Sterilizers, autoclaves, and batch reactors

Each application may differ, but the basics of pressure vessel design are consistent across use cases—ensuring integrity under pressure and protecting both workers and equipment.

Key Standards and Codes in the Basics of Pressure Vessel Design

ASME Boiler and Pressure Vessel Code (BPVC)

A central element in the basics of pressure vessel design is compliance with the ASME BPVC, particularly Section VIII, which governs the design, fabrication, testing, and inspection of pressure vessels.

Key ASME BPVC topics include:

- Material specifications and ratings

- Design calculations and formulas

- Welding and fabrication techniques

- Testing protocols (e.g., hydrostatic tests)

- Inspection and documentation requirements

Following the ASME BPVC ensures that the basics of pressure vessel design align with industry best practices and legal requirements.

Other Applicable Standards

- EN 13445 – Unfired Pressure Vessels (Europe)

- CSA B51 – Pressure Vessel Code (Canada)

- PED – Pressure Equipment Directive (EU compliance)

Adhering to these standards is fundamental when applying the basics of pressure vessel design in international manufacturing or global projects.

Material Selection and Structural Considerations

No discussion of the basics of pressure vessel design would be complete without material science. Materials must be chosen based on their strength, resistance to corrosion, temperature tolerance, and ability to meet code requirements.

Common materials used:

- Carbon steel

- Stainless steel

- Alloy steels (e.g., Inconel, Hastelloy)

Factors influencing material selection:

- Operating temperature and pressure

- Corrosiveness of contents

- Weldability and fabrication processes

All these considerations are at the core of the basics of pressure vessel design, ensuring long-term durability and safety.

Safety Mechanisms and Stress Analysis

Safety is a non-negotiable part of the basics of pressure vessel design. Proper design must account for:

- Internal pressure

- External forces

- Temperature gradients

- Fatigue due to cyclic loading

Design engineers perform finite element analysis (FEA) and stress calculations to ensure vessels can withstand these loads. Additionally, components such as pressure relief valves, rupture disks, and reinforced nozzle pads are integrated into the vessel as part of the safety strategy.

Mastering the Basics of Pressure Vessel Design

Mastering the basics of pressure vessel design empowers engineers, manufacturers, and plant operators to ensure safer operations, fewer failures, and code compliance across every project. Whether you’re specifying materials, choosing a fabricator, or reviewing blueprints, understanding these foundational principles is essential for successful pressure vessel deployment.

Materials Selection for Pressure Vessels

Choosing the right material is foundational to pressure vessel safety and performance. Material selection affects not only the strength and durability of the vessel but also its resistance to corrosion, fatigue, and thermal stress.

Factors Influencing Material Choice

- Pressure and Temperature: High-pressure environments require materials with excellent yield strength and temperature tolerance.

- Corrosive Media: For acidic or chemically aggressive contents, corrosion-resistant alloys or stainless steel are preferred.

- Weight and Cost: While exotic alloys may perform better, cost and manufacturability are often important trade-offs.

Common Materials Used

- Carbon Steel: A cost-effective option with good mechanical properties for moderate pressure applications.

- Stainless Steel: Provides superior corrosion resistance, especially in chemical processing environments.

- Chromoly Alloys (e.g., SA-387): Excellent strength-to-weight ratio for high-stress environments.

- Composite Materials (rare): Occasionally used in aerospace or specialized sectors.

Proper material testing and certification are required to ensure compliance with ASME and other standards.

Essential Design Considerations

Pressure vessels must be designed to safely contain the contents under a range of operating conditions. Here are some of the fundamental principles involved.

Wall Thickness and Pressure Calculations

Engineers calculate the required wall thickness based on:

- Design Pressure

- Material Strength

- Corrosion Allowance

- Manufacturing Tolerances

The formula commonly used under ASME Section VIII is:

t = (P * R) / (S * E – 0.6P)

Where:

- t = Wall thickness

- P = Internal pressure

- R = Internal radius

- S = Allowable stress

- E = Weld efficiency

Vessel Shapes: Cylindrical vs. Spherical

- Cylindrical vessels are easier and more cost-effective to manufacture.

- Spherical vessels distribute stress more evenly and are structurally more efficient but more expensive.

Design often involves trade-offs between structural performance and fabrication complexity.

Stress Types in Pressure Vessels

- Hoop Stress: Acts around the circumference of the vessel; usually the highest stress in cylindrical vessels.

- Longitudinal Stress: Runs lengthwise and is generally half of the hoop stress.

- Radial Stress: Typically minimal compared to the others but still considered in design.

Nozzles, Fittings, and Openings

Every opening in a vessel—whether it’s a nozzle, manway, or inspection port—introduces stress concentrations. Proper reinforcement and stress analysis are vital to avoid failure.

Safety Features and Risk Mitigation

Given the risks of operating under pressure, safety is paramount in vessel design and maintenance.

Pressure Relief Devices

- Safety Relief Valves: Automatically release pressure when it exceeds design limits.

- Rupture Discs: Burst at a preset pressure to protect against sudden overpressure events.

Both are required by ASME standards to protect personnel and equipment.

Testing Protocols

Before a vessel is put into service, it undergoes several critical tests:

- Hydrostatic Testing: Filling the vessel with water and pressurizing it to 1.5 times its design pressure.

- Radiographic Testing: Used to examine weld integrity.

- Ultrasonic Testing (UT): Detects wall thickness and flaws internally without destruction.

Non-Destructive Testing (NDT)

NDT ensures the vessel’s structural integrity without damaging the product. Other NDT methods include:

- Magnetic Particle Testing

- Dye Penetrant Testing

- Acoustic Emission

At Red River, our testing protocols are in strict alignment with ASME and client specifications. We also perform periodic inspections to maintain operational safety and compliance.

Pressure Vessel Design Basics

Mastering Pressure Vessel Design Basics empowers engineers and plant operators to ensure safe, reliable, and code-compliant operations. By integrating proper material selection, safety standards, and robust inspection routines, the risk of failures is minimized while equipment lifespan and performance are maximized.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions

1. What is a pressure vessel?

A pressure vessel is a container designed to safely store or transport fluids under pressure significantly different from atmospheric pressure.

2. Why is ASME code important in vessel design?

The ASME BPVC ensures safety and consistency in design, fabrication, testing, and maintenance of pressure vessels. Compliance is required to meet legal and insurance standards.

3. What materials are typically used in pressure vessels?

Common materials include carbon steel, stainless steel, and chrome-moly alloys. Material selection depends on pressure, temperature, and corrosion resistance needs.

4. How do engineers determine wall thickness?

Wall thickness is calculated using formulas that factor in design pressure, vessel diameter, material strength, and welding efficiency.

5. What’s the difference between hoop stress and longitudinal stress?

Hoop stress occurs around the circumference of a cylindrical vessel, while longitudinal stress acts along the vessel’s length. Hoop stress is typically greater.

6. Are pressure vessels always round?

Cylindrical and spherical shapes are most common, but custom shapes are sometimes used for specialized applications.

7. What types of safety features are included?

Relief valves, rupture discs, and other pressure-regulating devices prevent over-pressurization and failure.

8. How often should pressure vessels be inspected?

Inspections are conducted annually or as required by regulation. Non-destructive tests help detect internal flaws and material degradation.

Key Takeaways

- Pressure vessels are essential components in industries requiring pressurized fluid storage or transport.

- The ASME BPVC sets the gold standard for pressure vessel design and safety.

- Material choice influences performance, safety, and durability.

- Key design factors include wall thickness, stress analysis, and vessel shape.

- Safety systems and testing protocols are critical to avoid catastrophic failures.

- Partnering with experienced manufacturers like Red River ensures adherence to standards, precision in fabrication, and long-term reliability.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No subpillar set for this blog post.

About Author