Vertical and horizontal separators play essential roles in industrial separation processes, with vertical separators being more suitable for confined spaces and high-pressure applications, while horizontal separators excel in handling larger liquid volumes. Choosing the right separator depends on space constraints, flow rates, and pressure requirements.

The Basics of Vertical and Horizontal Separators

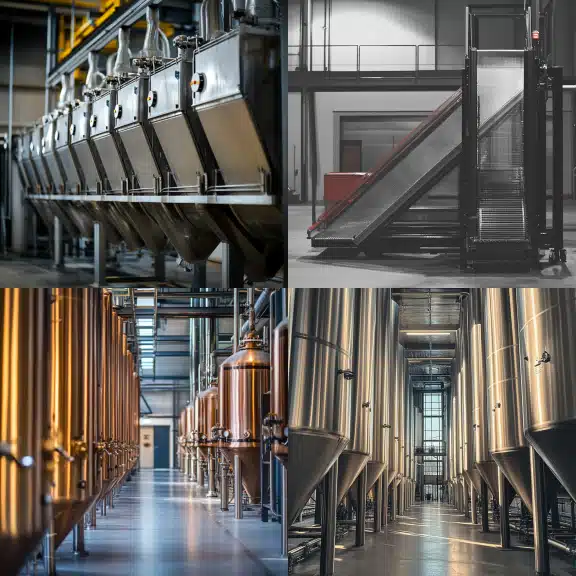

Vertical and horizontal separators are essential in industries where space is limited or the separation process involves high-pressure fluids. These separators are designed to reduce operational costs and excel when there is a significant density difference between substances being separated. Understanding their advantages and applications can help you choose the best separator for your needs.

Overview of Vertical Separators

Vertical separators are highly effective in managing high-pressure fluid separation, especially where space efficiency is critical. They perform well with mixtures that have notable density differences, ensuring optimal separation and cost reduction. Due to their compact design, vertical separators are ideal for applications like natural gas production, where installation in confined spaces is required.

However, it’s important to consider the need for vertical clearance during installation, which may require additional planning.

Overview of Horizontal Separators

Horizontal separators are designed to handle larger volumes of liquid and provide more surface area for separation. These separators excel in separating solids, liquids, and gases, making them ideal for applications involving heavier liquid loads, such as crude oil processing and wastewater treatment.

While horizontal separators need more floor space, their adaptability to higher flow rates and larger capacities makes them reliable in large-scale industrial operations.

Common Applications in Industrial Settings

Vertical and Horizontal Separators play critical roles across industries like oil and gas, chemical processing, and energy production. Vertical separators are best suited for environments where space is limited, or separation occurs under high pressure. In contrast, horizontal separators are ideal for handling higher liquid volumes, as seen in crude oil processing and wastewater treatment.

Key Differences Between Vertical and Horizontal Separators

Design and Structural Differences: Vertical separators stand upright and are compact, making them ideal for confined spaces. Horizontal separators, lying flat, provide more surface area for larger liquid volumes and are better suited for handling greater weight loads.

Efficiency and Performance Considerations: Vertical separators excel in high-pressure environments, while horizontal separators manage large liquid volumes and stable fluid interfaces effectively.

Space Requirements and Installation: Vertical separators require less floor space but need additional vertical clearance. Horizontal separators take up more floor space but are easier to install and maintain.

Choosing the Right Separator for Your Needs

When selecting a separator, consider the following factors:

- Composition of Substances: Assess the ratio of gas, liquid, and solids.

- Space Constraints: Determine whether a vertical or horizontal design is more practical.

- Flow Rates and Pressure Requirements: Evaluate the system’s flow rates and pressure needs

Industry-Specific Recommendations

Different industries have unique requirements that influence separator choice:

- Oil and Gas: Vertical separators are preferred for gasoline-heavy streams due to their compact design and efficiency.

- Power and Chemical Processing: Horizontal separators are often favored for large liquid volumes, as they offer greater handling capacity and flexibility.

The right choice depends on the operational demands and the specific characteristics of the substances being separated.

Cost vs. Benefit Analysis

Cost is an important factor, but the long-term benefits of each separator should also be considered. Horizontal separators may have higher initial costs, but their ability to handle larger volumes and provide easier maintenance may result in financial savings over time. Vertical separators, while more compact, offer better value in installations with limited space.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

What are the main programs of vertical and horizontal separators in the oil and gas industry?

Vertical and horizontal separators are widely used within the oil and gas industry, but their packages differ primarily based on the specific wishes of the operation. Vertical separators are frequently used in situations in which the gas-to-liquid ratio is high, making them perfect for gas processing facilities or herbal gasoline wellheads. These separators successfully deal with gasoline separation from drinks, ensuring that the gas circulate is easy and ready for similar processing. Horizontal separators, however, are more suitable for situations in which the liquid content is higher, which include crude oil processing or in packages in which oil, fuel, and water need to be separated. Their design allows for more powerful liquid management, making them essential in downstream operations wherein oil-water separation is vital.

How do environmental factors impact the selection between vertical and horizontal separators?

Environmental elements play an enormous function in determining whether a vertical or horizontal separator is more suitable for specific software. For example, in offshore operations where space is a premium, vertical separators are regularly preferred because of their smaller footprint. They absorb less deck area, which is a vital attention in offshore structures. Conversely, in onshore facilities wherein there’s greater available horizontal space, horizontal separators may be chosen for his or her capacity to handle large volumes and provide less difficult entry for preservation. Additionally, elements consisting of ambient temperature, pressure conditions, and the presence of corrosive factors can affect the cloth selection and layout of the separator, similarly affecting the choice between vertical and horizontal configurations.

Can vertical and horizontal separators be custom-designed to satisfy precise operational needs?

Yes, each vertical and horizontal separator may be incredibly customized to meet the precise wishes of an operation. Customization alternatives encompass the selection of materials (consisting of carbon metallic, chrome steel, or specialized alloys), the design of internal components (like baffles, weirs, or coalescing plates), and the integration of instrumentation and manipulation systems. These customizations are important for optimizing the separator’s overall performance in distinctive environments. For instance, in corrosive environments, a separator is probably covered with special coatings or produced from corrosion-resistant materials. Similarly, the inner design may be tailor-made to enhance separation performance, lessen pressure drop, or control specific go-with-the-flow characteristics precise to the operation.

What maintenance considerations have to be taken into account for vertical and horizontal separators?

Maintenance is an essential aspect of ensuring the long-term reliability and performance of both vertical and horizontal separators. Vertical separators, because of their compact design, can be extra difficult to get admission to for maintenance, mainly in restricted spaces. However, they normally have fewer inner components, which can simplify some aspects of renovation. Horizontal separators, even as easier to get admission to, often have more complicated inner structures that require regular inspection and upkeep to make certain most advantageous performance. Key maintenance responsibilities encompass monitoring and cleansing of internal components, checking for corrosion or put on, and ensuring that every instrumentation and manipulation structure is functioning efficaciously. Regular protection schedules and inspections are critical to stopping costly downtime and ensuring that the separators hold to perform efficiently.

How do vertical and horizontal separators handle fluctuations in flow costs and pressure?

Both vertical and horizontal separators are designed to handle variations in waft costs and pressure, however their overall performance in fluctuating situations can vary. Vertical separators are normally better suited for managing excessive-pressure situations and can speedy regulate changes in flow rates because of their compact layout and shorter liquid retention times. This makes them mainly effective in applications wherein gasoline float rates can vary appreciably. Horizontal separators, with their larger floor vicinity and longer retention instances, are better at managing consistent float quotes with minor fluctuations. They offer greater constant separation performance in packages wherein liquid volumes are noticeably strong however also can be designed with capabilities like variable weirs or adjustable baffles to accommodate larger versions in drift and pressure. Understanding these dynamics is essential for choosing the right separator for operations with fluctuating conditions.

Key Takeaways:

- Vertical separators are compact and ideal for high-pressure, space-limited environments.

- Horizontal separators handle larger liquid volumes and offer better flexibility for larger-scale operations.

- Key factors in choosing a separator include the composition of substances, available space, and flow rate requirements.

- The right choice depends on both cost and long-term performance benefits.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No related articles found.

About Author