Coalescing Filters Guide for Enhancing Industrial Filtration Efficiency

Coalescing filters guide industrial operators on how to effectively remove liquid contaminants, oil mist, and particulates from air and gas streams. These filters improve system performance, extend equipment lifespan, and reduce operational costs. Proper maintenance and inspection ensure they operate efficiently while complying with pressure vessel safety standards. Red River provides expert guidance and reliable filtration solutions to maximize your equipment’s efficiency. Understanding coalescing filters and their applications is essential for maintaining clean and safe industrial systems.

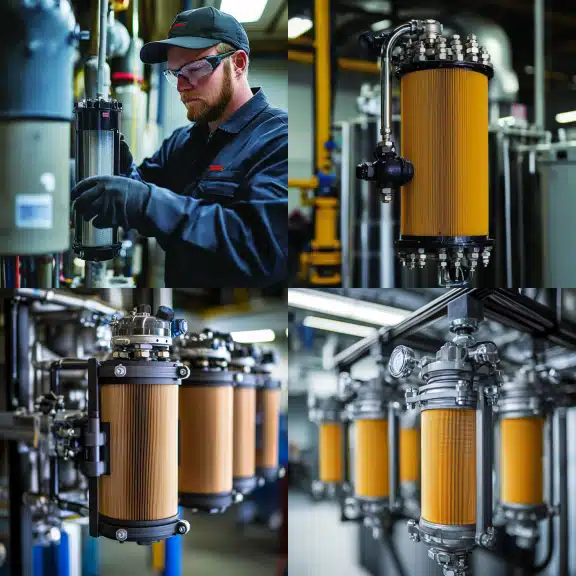

Coalescing Filters Guide Explained for Better System Protection

A coalescing clear-out is an important component in many industrial systems, designed to do away with the best oil mist, water vapor, and other contaminants from compressed air and gas streams. These filters work using forcing the compressed air or gasoline via a media that captures the tiny droplets and debris, merging them into larger droplets that can be drained away. This system ensures that the air or fuel is clean and dry, which is vital for the green operation of your device.

How Do Coalescing Filters Work?

Coalescing filters perform by utilizing a specialized filter media that encourages the merging of small debris and droplets. As the tainted air or gasoline passes via the filter, the media traps the tiny droplets and particles. Over time, those trapped elements coalesce or integrate into larger droplets. These larger droplets then flow to the bottom of the filter-out housing, where they accumulate and drain away. This manner guarantees that the output air or fuel is unfastened from contaminants, defending your device from harm and ensuring foremost performance.

Common Applications of Coalescing Filters

Coalescing filters are widely used across diverse industries due to their effectiveness in casting off contaminants from air and gas streams. Some commonplace programs include:

- Industrial Use: Essential in manufacturing tactics to ensure the purity of compressed air.

- Air Compressors: Protects system and improves performance by getting rid of oil mist and water vapor.

- HVAC Systems: Enhances air fine and system performance with the aid of doing away with particulate count numbers.

- Oil and Water Separation: Crucial in oil and gas industries to split contaminants from produced gas.

- Automotive Applications: Ensures clean air supply to pneumatic gear and structures.

Key Features of the Best Coalescing Filters

Efficiency and Performance

The first-rate coalescing filters are designed to maximize performance and overall performance, making sure that contaminants such as oil mist, water vapor, and particulates are successfully eliminated from air and fuel streams. High-efficiency coalescing filters can capture even the smallest debris, ensuring that your structures run smoothly and reliably. This stage of overall performance is vital in business programs, in which smooth air and gasoline are vital for maintaining the integrity of equipment and procedures.

Durability and Maintenance

Durability is a key characteristic of top-rated coalescing filters. Constructed from tremendous substances, those filters are constructed to resist harsh commercial environments and prolonged use. Maintenance is also simplified with long-lasting coalescing filters, as they’re designed for clean inspection and alternative. This reduces downtime and guarantees that your operations are preserved without interruption. Investing in durable filters means fewer replacements and lower renovation charges over the years, presenting lengthy time period costs.

Compatibility with Different Systems

The exceptional coalescing filters provide compatibility with a wide range of structures, making them versatile and adaptable for various applications. Whether you need filters for HVAC systems, compressed air systems, or specific business uses, it’s essential to pick out coalescing filters that could seamlessly combine with your existing setup. Compatibility guarantees that you can reap ideal performance without needing sizeable adjustments or extra additives, making it less difficult to preserve and improve your structures as desired.

Top Coalescing Filters on the Market

Best Coalescing Filters for Industrial Use

When it involves commercial packages, the satisfactory coalescing filters are people who provide superior contaminant elimination and strong creation. These filters are designed to deal with high volumes of air or gas, ensuring that structures operate correctly and without interruptions. Top brands in this category provide filters that excel in disposing of oil mist, water vapor, and particulates, making them perfect for a whole lot of business processes.

High-Rated Coalescing Filters for Air Compressors

Air compressors require high-rated coalescing filters to keep optimal performance and sturdiness. The pleasant filters in this class are known for his or her capacity to seize the best debris and prevent oil and moisture from reaching downstream devices. These filters now not only enhance the efficiency of air compressors but additionally reduce maintenance fees and improve the lifestyles of the device. Look for filters which have wonderful critiques and ratings for reliability and effectiveness.

Coalescing Filters for Oil and Water Separation

In the oil and gasoline industry, coalescing filters play a critical position in separating oil and water from produced fuel. The pinnacle coalescing filters for oil and water separation are engineered to deal with the particular demanding situations of this software, offering high-efficiency separation and minimum maintenance. These filters are built to withstand harsh environments and supply constant overall performance, making sure of the purity of the gas and protecting the downstream device from contamination.

How to Choose the Right Coalescing Filter for Your Needs

Factors to Consider When Buying a Coalescing Filter

Selecting the right coalescing filter includes considering several key elements. First, compare the specific contaminants you want to dispose of, along with oil mist, water vapor, or particulates. Next, remember the operating conditions, together with pressure, temperature, and float price. The filter’s performance rating, normally expressed in microns, may also be important. Higher-efficiency filters seize smaller particles, which is crucial for essential applications. Additionally, assess the filter out’s compatibility with your existing machine and make sure it meets relevant industry standards.

Comparing Different Brands and Models

When comparing coalescing clear-out manufacturers and fashions, recognition of performance, durability, and cost. Look for filters from official producers acknowledged for fine and reliability. Read critiques and scores to gauge actual global performance and consumer satisfaction. Compare the specs of different fashions to find one which first-class suits your needs. It’s also crucial to not forget the whole value of ownership, inclusive of the initial buy price, maintenance, and replacement frequency.

Tips for Optimal Coalescing Filter Performance

To gain the most effective overall performance from your coalescing filter out, make certain regular preservation and well-timed replacements. Follow the producer’s recommendations for inspection and cleansing to prevent clogging and decrease performance. Monitor pressure drops across the filter, as widespread will increase can suggest the want for preservation or substitute. Additionally, make sure the right installation and device integration to avoid leaks and ensure effective filtration.

Coalescing Filters Guide for Optimal System Operation

Understanding coalescing filters and maintaining them properly is essential for safe, efficient, and reliable industrial systems. Adhering to pressure vessel safety standards and compliance ensures operational longevity and reduced costs. Red River’s expertise in coalescing filter maintenance helps businesses optimize system performance while safeguarding equipment.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

1. What industries commonly use coalescing filters?

Coalescing filters are widely used in oil and gas, petrochemicals, manufacturing, HVAC systems, and automotive applications to remove oil, water, and particulates.

2. How do coalescing filters improve system efficiency?

By removing small droplets and contaminants, coalescing filters ensure clean air or gas, reduce wear on equipment, and maintain optimal system performance.

3. How often should coalescing filters be inspected or replaced?

Inspection frequency depends on contaminants and system use. Typically, filters should be checked regularly, and replacement is guided by performance indicators such as pressure drop.

4. Can coalescing filters handle both air and liquid streams?

Yes. Coalescing filters are effective for compressed air, gas, and liquid streams, providing versatile filtration for various industrial applications.

5. How do coalescing filters comply with pressure vessel safety regulations?

Filters are designed and maintained in line with pressure vessel inspection and maintenance standards, ASME code for pressure vessel safety, and industry-specific guidelines.

6. What maintenance practices extend filter lifespan?

Regular cleaning, inspection for wear, using approved replacement parts, and adhering to manufacturer instructions all contribute to longer-lasting filters.

7. What are the signs a filter needs maintenance?

Indicators include increased pressure drop, reduced system flow, unusual noise, or visible contamination in the filter media.

Key Takeaways

- Coalescing filters remove oil, water, and particulates, protecting equipment

- Regular maintenance and inspection ensure long-term efficiency

- Choosing the right filter requires considering contaminants, system conditions, and efficiency ratings

- Compliance with pressure vessel safety standards and ASME code is critical

- Partnering with Red River ensures reliable, high-performance filtration solutions

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No related articles found.

About Author