Rolled Steel Beams The Complete Guide

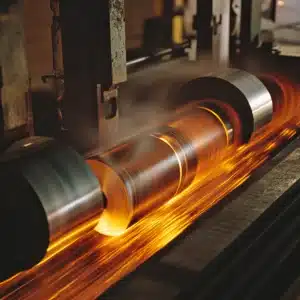

Introduction to Rolled Steel Beams Rolled steel beams play a vital role in construction and manufacturing around the world. Engineers create these beams by passing steel through rollers to achieve specific profiles and sizes. This process delivers beams with strength, flexibility, and reliability. As a result, rolled steel beams form the backbone of buildings, bridges, and industrial plants. If you want to know why these beams matter and how to choose them, this guide will walk you through every essential