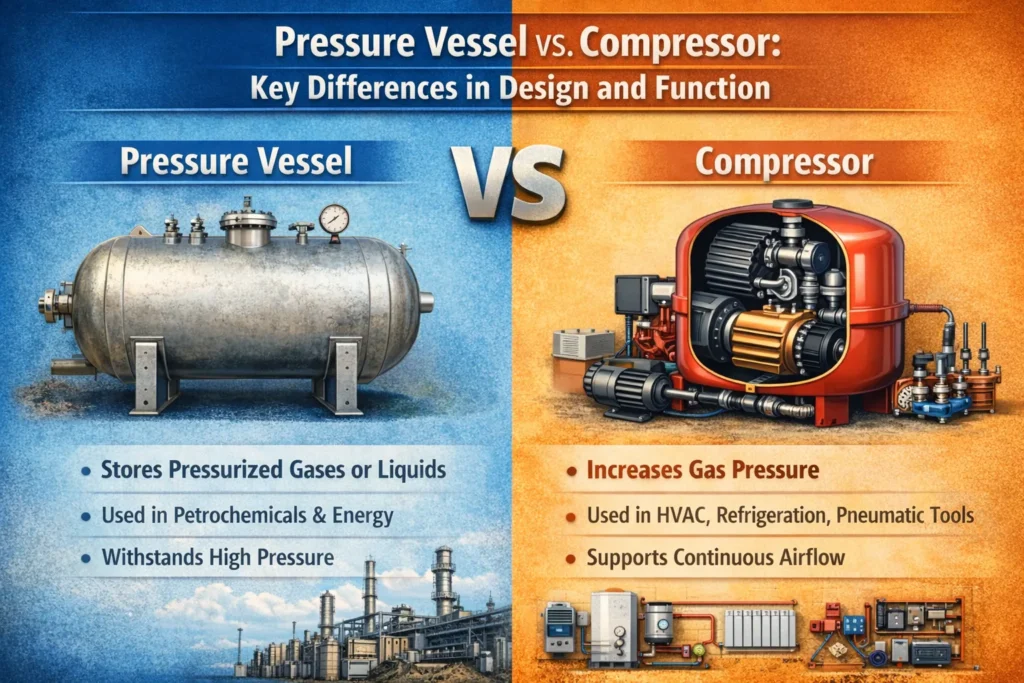

Pressure Vessel vs. Compressor: Unraveling the Distinctions

In many industrial systems, both pressure vessels and compressors are essential components, but they serve vastly different purposes. Pressure vessels store pressurized liquids or gases, while compressors increase the pressure of gases by reducing their volume. Understanding the core functions and applications of each will help industries make informed decisions when selecting the right equipment […]

Pressure Vessel vs. Expansion Tank: Distinguishing the Two

Pressure vessels are designed for storing or processing gases and liquids at high pressures, typically used in industries like petrochemical and power generation. They adhere to strict safety and regulatory standards, such as the ASME Boiler and Pressure Vessel Code (BPVC). On the other hand, expansion tanks are specialized components that manage thermal expansion in […]

Understanding Pressure Vessels: The Case of Water Boilers

Understanding Pressure Vessels: The Case of Water Boilers Pressure vessels play an integral role in various industrial systems, particularly in sectors that require high-pressure containment, such as energy, chemical processing, and manufacturing. At Red River, we specialize in the precise manufacturing of custom pressure vessels, ensuring safety, efficiency, and durability in every project. One key […]

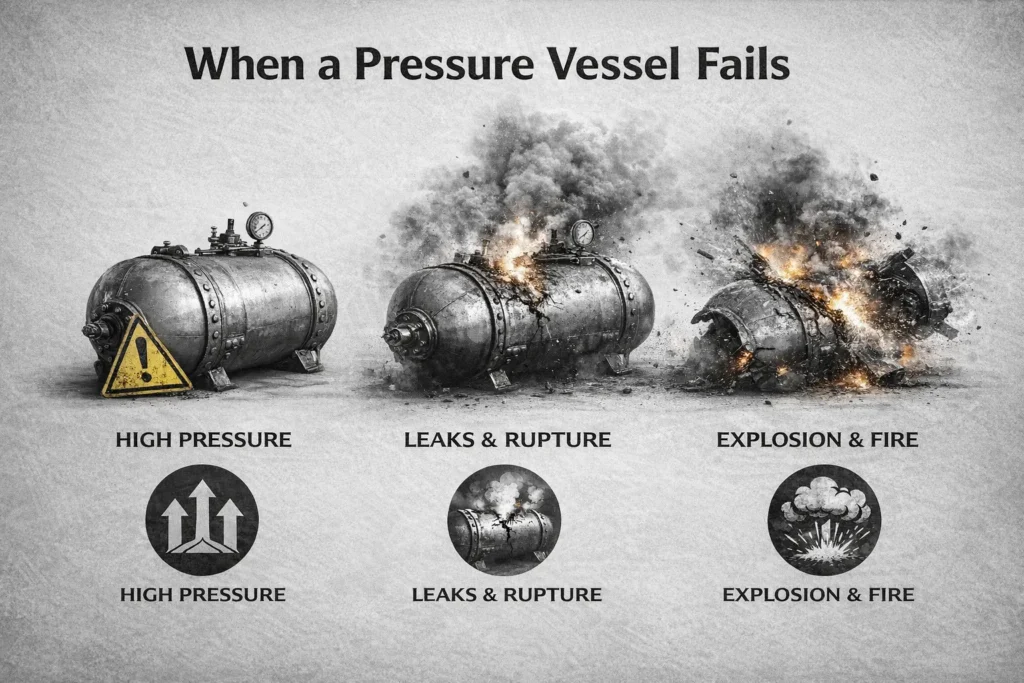

When a Pressure Vessel Fails: Unmasking the Consequences

Pressure vessel failures are catastrophic events with immediate and far-reaching consequences. From explosive releases of gas and hazardous materials to environmental and economic ramifications, these failures can result in severe injuries, downtime, and costly damages. Understanding the causes, impact, and mitigation strategies is essential to ensure safety in high-risk industries. Introduction to Pressure Vessel Failure […]

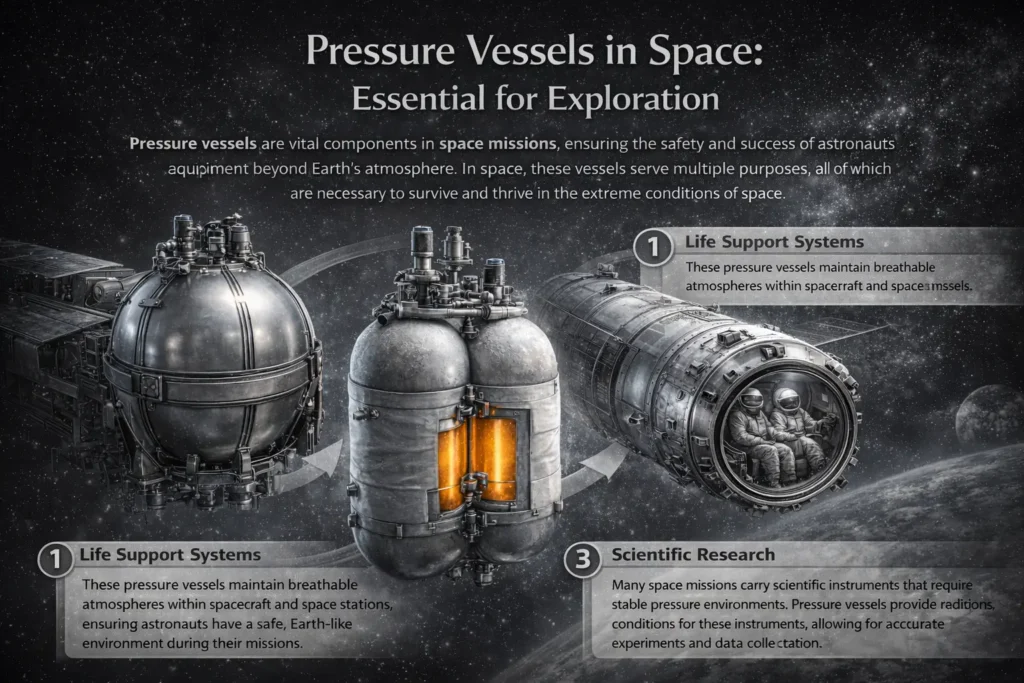

Galactic Containers: The Essential Role of Pressure Vessels in Space Exploration

Pressure vessels in space are essential for ensuring the safety and success of space exploration. They provide the necessary pressure for life support, propellant storage, and scientific experiments, and protect astronauts and equipment from the harsh environment of space. Why Pressure Vessels are Vital for Space Exploration Space exploration is a monumental challenge, pushing the […]

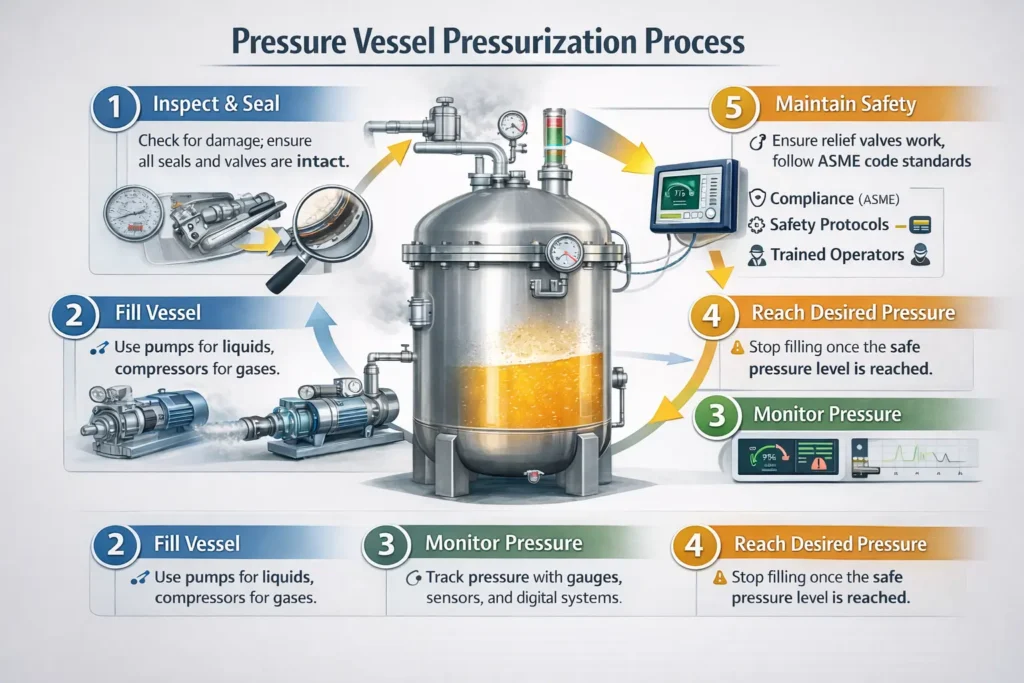

Mastering the Art of Pressure Vessel Pressurization

Pressurizing a pressure vessel involves carefully filling it with gas or liquid at high pressure using pumps or compressors, while ensuring safety through constant monitoring and adherence to engineering standards. The process requires proper sealing, pressure relief mechanisms, and trained operators to maintain the pressure vessel’s integrity. Pressure vessel pressurization is critical to safe operation […]

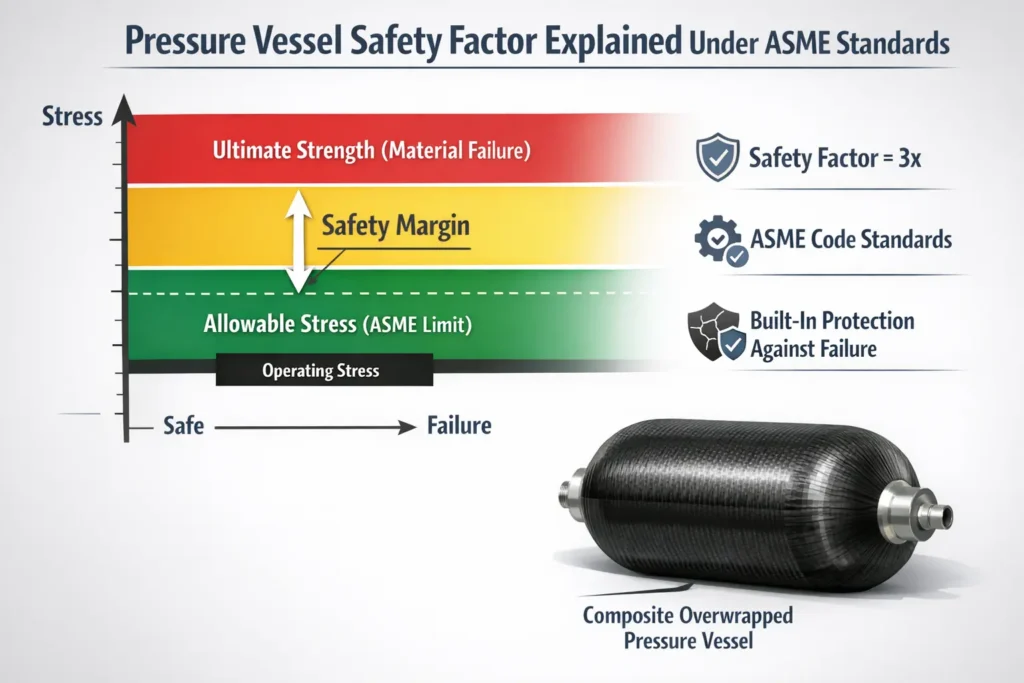

Understanding Pressure Vessel Safety Factors: Essential Guidelines

Pressure vessel safety factors define the margin between normal operating stress and material failure to ensure safe and compliant operation. Under ASME Section VIII Division 1, typical safety factors range from 3.5 to 4, with adjustments required for composite overwrapped pressure vessels and extreme conditions like cryogenic service. Proper safety factor selection depends on material […]

ASME Factor for Pressure Vessels

The ASME factor of a pressure vessel In the ASME Boiler and Pressure Vessel Code (BPVC), the term “ASME factor” usually refers to the design safety factor or allowable stress factor. This factor defines the relationship between a material’s ultimate tensile strength (or yield strength) and the allowable stress value used in design calculations. For […]

What ASME Defines as a Pressure Vessel | ASME BPVC Section VIII Guide

A pressure vessel is a specially engineered container that safely holds gases or liquids at pressures far from ambient conditions. This guide explains what pressure vessels are, how they work, and why precise descriptions matter for safety and compliance. It covers major types (storage vessels, heat exchangers, reactors, boilers), key standards like ASME BPVC Section […]

Essential Criteria for Designing a Pressure Vessel

Introduction to the criteria for a pressure vessel Pressure vessels are containers designed to hold gases or liquids at a pressure substantially different from ambient pressure. The design, manufacturing, and operation of pressure vessels are governed by design codes and standards to ensure safety. The criteria for a pressure vessel can vary based on the […]