Key Welding Challenges in High-Pressure Vessel Fabrication

Welding is pivotal in ensuring the vessels can withstand extreme conditions and maintain structural integrity in high-pressure vessel fabrication. However, several common welding challenges in high-pressure vessel manufacturing must be addressed for success. At Red River, we specialize in overcoming these challenges by leveraging our expertise, advanced technology, and commitment to quality. Here’s how we […]

Understanding the Difference Between Pipes and Pressure Vessels

Pipes and pressure vessels may both carry pressurized fluids, but they serve different purposes and follow distinct design standards. Pipes are primarily transport systems with lower pressure ratings, while pressure vessels are engineered to safely contain high-pressure substances over time. Misclassifying one as the other can lead to serious safety, compliance, and cost issues. Learn […]

What Are WRAS Water Regulations? Compliance & Safety Guide

WRAS water regulations (Water Regulations Advisory Scheme) ensure that any component in contact with the UK’s public water supply meets essential safety and hygiene standards. Whether you’re manufacturing potable water tanks, GRP vessels, or polymer fittings, WRAS approval is often a legal and operational requirement. At Red River, we help clients navigate the WRAS approval […]

Stainless Steel Production Costs

Stainless Steel Production Costs are shaped by multiple factors including raw materials, labor, energy use, machinery, and compliance requirements. These elements influence the durability, reliability, and long-term value of stainless steel components used in pressure vessels and related applications. Understanding these cost-driving factors helps project planners make informed decisions while ensuring quality and safety. At […]

Spherical Cryogenic Tank Advantages

Spherical cryogenic tanks offer exceptional efficiency, durability, and stability for storing materials at extremely low temperatures. Their geometry minimizes heat transfer, improves pressure distribution, and delivers long-term reliability in demanding industrial environments. Understanding Spherical Cryogenic Tank Advantages helps operators choose systems that support safety, consistency, and compliance with modern standards. These tanks remain a preferred […]

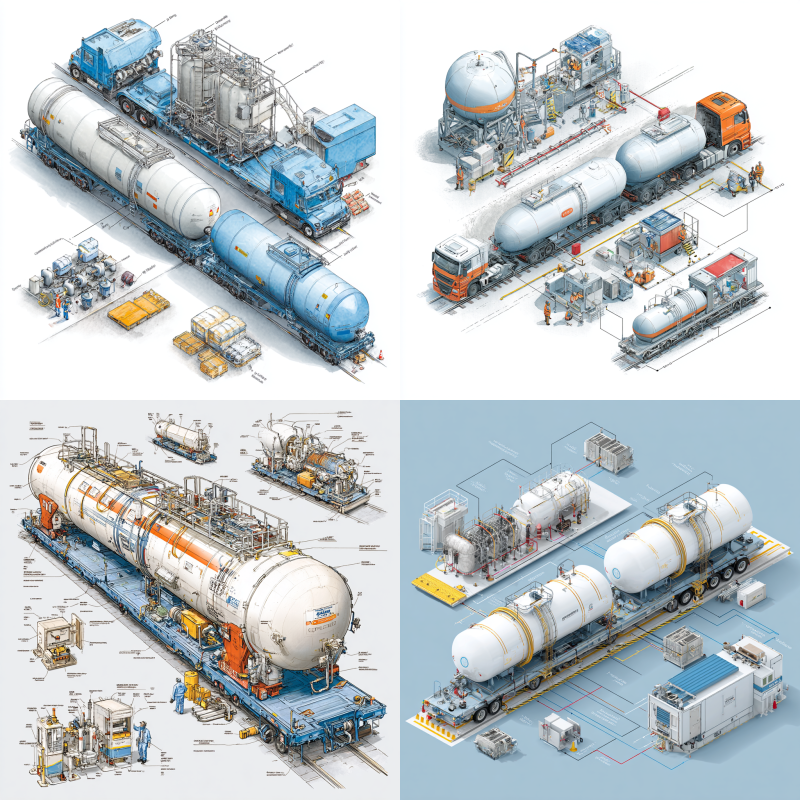

Cryogenic Liquid Transportation

Cryogenic Liquid Transportation is essential for safely moving extremely cold substances such as nitrogen, oxygen, and argon. This process requires specialized equipment, strict safety standards, and careful handling to maintain temperature integrity and prevent accidents. Different transportation modes—road, rail, maritime, air, and pipeline—offer unique advantages and challenges. Red River ensures high-quality solutions that adhere to […]

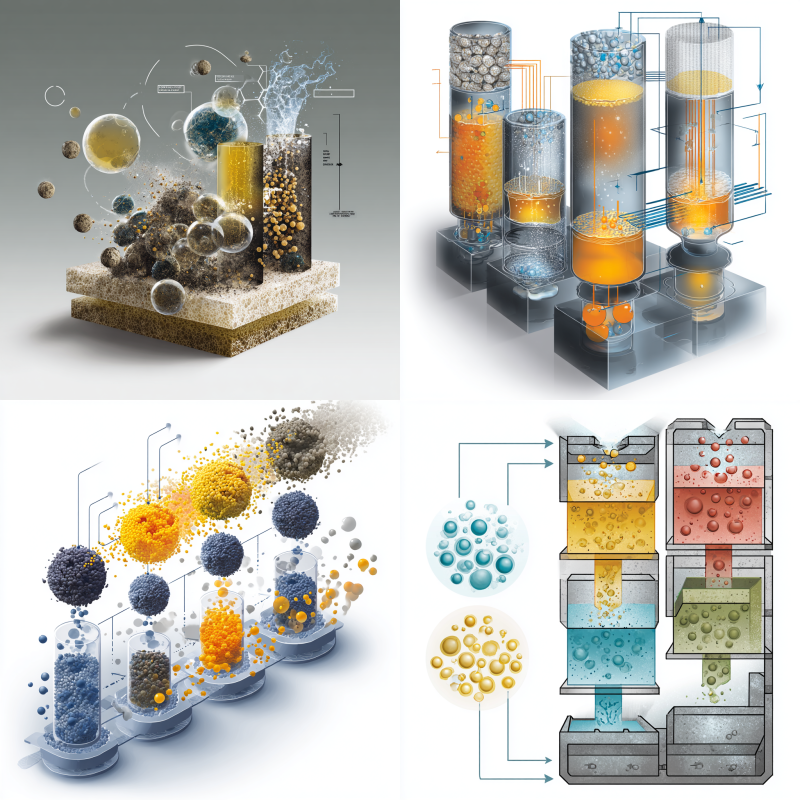

Understanding Coalescing: What It Means and Its Importance

Understanding Coalescing is essential in many industries where separating small particles or droplets from fluids or gases ensures operational efficiency and product quality. This process improves filtration, enhances performance, and extends equipment lifespan. At Red River, we provide advanced coalescing solutions designed for durability and optimal performance. Incorporating these methods helps industries maintain compliance with […]

Innovations in Welding Technology Revolutionizing the Industry

Innovations in Welding Technology are transforming fabrication processes, improving precision, safety, and efficiency. From robotic welding and laser techniques to AI-powered systems and 3D printing, these advancements address modern manufacturing challenges. Red River integrates these technologies to deliver high-quality pressure vessels and fabricated products. By combining automation, sustainability, and data-driven insights, the industry is achieving […]

The Evolution of Dehydrator Design

[ez-toc] Modern dehydrators have evolved through advanced materials and smart technologies, delivering faster drying, higher energy efficiency, and better product quality. Red River leads this innovation by combining durable, sustainable materials with automation, IoT, and energy-efficient systems across multiple industries. Innovative Dehydrator Design and Materials: Efficiency & Innovation At Red River, we recognize that innovation […]

Innovative Dehydrator Design and Materials: Efficiency & Innovation

Innovative Dehydrator Design and Materials are essential for modern industries seeking efficient, durable, and sustainable drying systems. At Red River, we integrate high-performance alloys, heat-resistant polymers, and advanced technologies to optimize dehydrator performance. These innovations improve energy efficiency, reduce maintenance costs, and ensure consistent product quality. Smart automation and IoT connectivity further enhance operational control […]