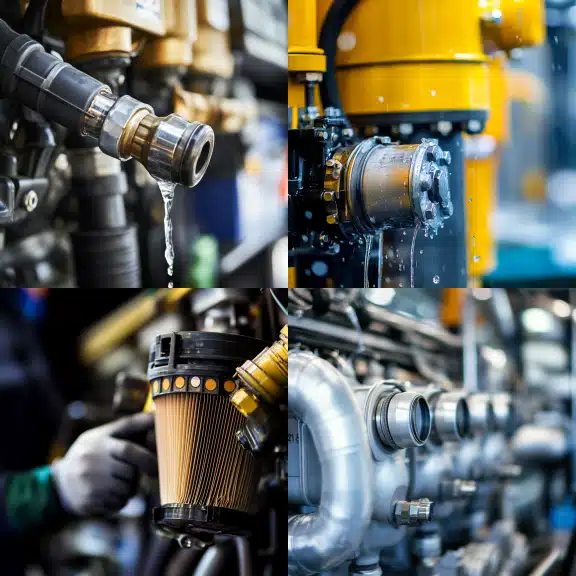

Do Diesel Fuel Filters Stop Water? Everything You Need to Know

Water in diesel fuel can lead to severe engine damage. Diesel fuel filters are your first line of defense, especially when paired with a water separator. Regular maintenance and smart fuel handling practices help prevent water-related issues and keep your engine running efficiently. Understanding the Importance of Diesel Fuel Filters in Preventing Water Contamination Water […]

Why It Is Important to Drain Water from Your Fuel Manager?

Water in your fuel manager is more than a nuisance—it’s a serious risk to your diesel engine. If left unchecked, it leads to rust, injector damage, and system failure. Draining your fuel manager regularly—every 3 to 6 months—is critical. Follow a safe, step-by-step process, and choose a properly sized, high-quality fuel manager for your operating […]

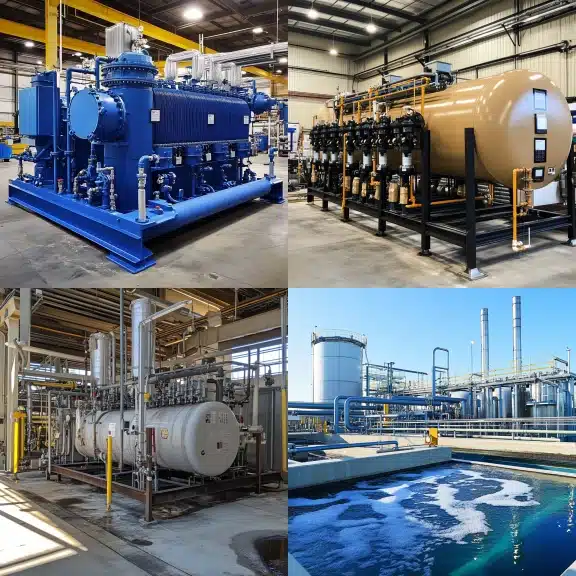

Understanding Water Separation in Industrial Applications

Efficient water separation in industrial applications protects equipment, reduces downtime, and supports compliance with environmental standards. Methods like gravity separation, coalescers, and filtration are vital to maintaining clean process streams. Poor water removal leads to corrosion, system failure, and regulatory issues. At Red River, we tailor water separation solutions to each operation, ensuring maximum efficiency […]

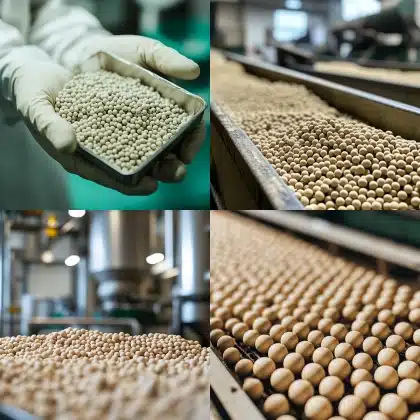

Are Molecular Sieves Expensive? Understanding the Costs and Value

Are molecular sieves expensive? While the upfront cost can be higher than other desiccants, their precision, efficiency, and long-term durability make them a smart investment. They outperform silica gel and activated carbon in moisture control, especially under demanding industrial conditions. The value of molecular sieves becomes clear in reduced downtime, improved product quality, and extended […]

How to Dry the Molecular Sieve: A Complete Guide

[ez-toc] Tips for Effective Regeneration Molecular sieves are an essential component in many industrial and laboratory processes, especially when it comes to drying gases and liquids, purifying air, or separating molecules by size. A common question that arises is: Can you dry molecular sieve? The simple answer is yes, molecular sieves can be dried and […]

All About Molecular Sieves

A molecular sieve is a highly selective filtration material that separates molecules based on size using precise pore structures. Common in gas drying, petrochemical processing, and industrial filtration systems, sieves like 3A, 4A, and 5A enable targeted removal of moisture and impurities. Zeolites and activated carbon are typical examples used in pressure vessels to optimize […]

What is Molecular Sieving? Principles, Types & Uses

Molecular sieves are advanced filtration materials with uniform pore sizes that selectively adsorb specific molecules. Used across oil, gas, pharma, and chemical industries, they offer ultra-low moisture control, gas purification, and VOC removal. Types like 3A, 4A, and 5A each serve specialized purposes, from dehydration to hydrocarbon separation. With long service lives and high regeneration […]

3A Molecular Sieve: Complete Guide for Industrial Drying & Separation

4A and 3A molecular sieves are zeolite-based desiccants that differ primarily by pore size—4 angstroms for 4A, and 3 angstroms for 3A. This difference determines their suitability for specific applications, like drying ethanol (3A) versus general moisture removal (4A). Choosing the right type ensures more efficient adsorption, protects product purity, and enhances operational efficiency. Red […]

Activating Molecular Sieves

Activating molecular sieves is essential for achieving their full adsorption capacity in industrial filtration systems. Proper activation involves controlled heating to remove moisture and impurities. Inadequate activation reduces performance, while overheating can permanently damage the sieves. Tailoring activation to the specific type of sieve ensures optimal efficiency. RedRiver LLC provides custom pressure vessels to support […]

Understanding the Importance of Properly Washing Molecular Sieves

Properly washing molecular sieves is critical to maintaining their adsorption efficiency and extending their lifespan. RedRiver LLC emphasizes best practices in cleaning, regenerating, and inspecting these vital components. Ignoring proper maintenance can result in equipment failure and costly downtime. This blog outlines key steps and tips to help ensure your sieves stay in peak condition. […]