Marine Engineer vs. Ship Engineer

Understanding the difference between a marine engineer vs. ship engineer is essential for anyone exploring engineering careers in the maritime sector. These professions share similarities but have distinct responsibilities, skill sets, and areas of specialization. Marine engineers mainly focus on propulsion and mechanical systems, while ship engineers oversee broader vessel operations, including structural and electrical […]

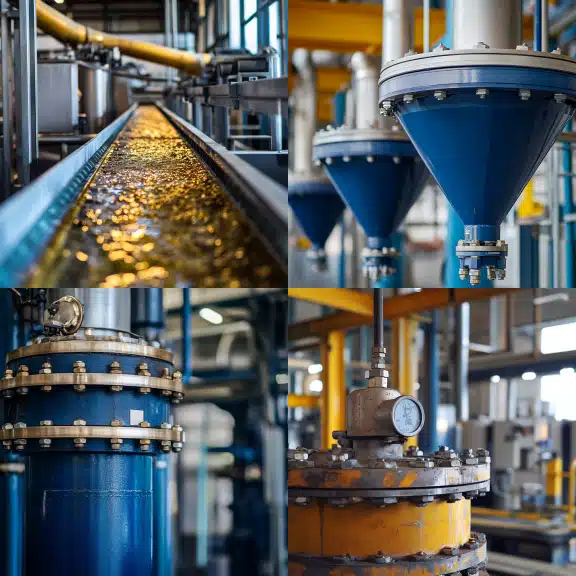

Role of a Pressure Vessel Welder

Pressure vessel welders are skilled specialists who fabricate containers designed to hold pressurized gases or liquids, following strict safety and quality standards like ASME codes. At Red River, our welders combine technical expertise with advanced materials and modern welding technologies to serve industries like oil, gas, biogas, and power. This article covers their responsibilities, required […]

Life Expectancy of Pressure Vessels

Pressure vessels are vital to industries like oil, gas, and energy. Their lifespan depends on design, materials, environment, and maintenance. Red River designs vessels to last, with strong materials, smart engineering, and support for ongoing care. Regular inspections and proper upkeep are key to durability. Choose Red River for vessels built with precision, purpose, and […]

Maximizing Fatigue Life of Pressure Vessels

Pressure vessels operate through repeated cycles of pressurization, temperature changes, and mechanical loads. Over time, these conditions can lead to fatigue a gradual deterioration that affects the vessel’s ability to perform safely and reliably. Maximizing fatigue life of pressure vessels is essential for achieving long-term performance, reducing unplanned downtime, and maintaining safety across various industrial […]

What is the Meaning of Retention Time in Separators

Retention time in a separator refers to the amount of time a substance stays within the separator during the separation process. Proper retention time is critical for maximizing separation efficiency, ensuring high product quality, and reducing operational costs. Optimizing retention time improves system performance, lowers downtime, and enhances overall operational profitability. What is Retention Time […]

Exploring Cryogenic Liquid Tank Venting: Understanding Normality

Cryogenic tank venting is the controlled release of vapor to prevent overpressure and ensure safety. It’s caused by factors like temperature fluctuations, pressure buildup, and insulation quality. This guide covers why venting happens, how to manage it, and what safety protocols and regulatory standards apply. Key tactics include using high-performance insulation, maintaining relief valves, and […]

Unlocking the Power of Pressurized Nitrogen Tanks

Nitrogen tanks are essential across industries for safe, pressurized storage and delivery of inert gas. This guide covers how they work, what affects their pressure (like temperature and altitude), and why proper certifications like ASME Section VIII matter. We also explain the benefits of pressurized storage, maintenance tips, and key safety factors plus how to […]

Understanding Cryogenic Distillation Pressure

Cryogenic distillation pressures are crucial for optimizing efficiency, purity, and control in industrial gas separation processes. Pressure impacts boiling points, separation quality, and energy use. Mastering pressure dynamics like control strategies, system design, and recent tech advances can dramatically boost performance and reliability. This guide covers key factors, challenges, and solutions for managing pressure in […]

Exploring Cryogenic Liquid Cylinders

Cryogenic liquid cylinders store and transport ultra-cold fluids like nitrogen and oxygen, essential across industries from healthcare to aerospace. They come in low-pressure (25–150 psi) and high-pressure (300+ psi) variants, each suited to specific operational needs. Low-pressure models are ideal for controlled, cost-effective dispensing; high-pressure versions support high-flow, long-duration uses. Choosing the right type depends […]

Understanding the Pressure of Nitrogen Gas Key Concepts and Applications

Liquid nitrogen, a cryogenic fluid cooled below -320°F (-196°C), is widely used in medicine, manufacturing, food, and science. Its critical pressure is 492 psia (3.4 MPa) above this, nitrogen becomes a supercritical fluid, which can compromise vessel safety. Maintaining pressure well below this threshold is essential. Engineers must consider temperature, material stress, and safety protocols […]