Why Must Separators Be ASME Pressure Vessels for Safety

Fuel water separators must be ASME pressure vessels because certification ensures safety, compliance, and durability under extreme conditions. This protects both workers and operations. Why Must Separators Be ASME Pressure Vessels in Industry? Fuel water separators play a crucial role in many industries, from oil and gas to public works, because they keep contaminants out […]

Types of Mechanical Failure

Mechanical failure in engineering, especially pressure vessel design, occurs in two main forms: ductile and brittle failure. Ductile failure involves visible deformation before breaking, offering safety warnings, while brittle failure is sudden and catastrophic with little to no warning. Factors like temperature, strain rate, material microstructure, and environmental exposure influence failure behavior. Engineers must consider […]

Why Are Industrial Fuel Water Separator Vessels Important

Industrial fuel water separator vessels remove water and contaminants from fuel, ensuring safety, preventing corrosion, and extending equipment life. They are vital in energy, chemical, and manufacturing industries. Understanding Why Are Industrial Fuel Water Separator Vessels Important Imagine working in an environment where even a drop of water in a fuel line can lead to […]

How Does an Industrial Fuel Water Separator Vessel Work

An industrial fuel water separator vessel uses density differences, baffles, and coalescing filters to separate water from fuel. This process ensures clean fuel, prevents corrosion, and keeps industrial engines running smoothly. Understanding How Does an Industrial Fuel Water Separator Vessel Work Separating fuel from water is vital for preventing engine damage, delays, and quality issues, […]

What Is an Industrial Fuel Water Separator Vessel

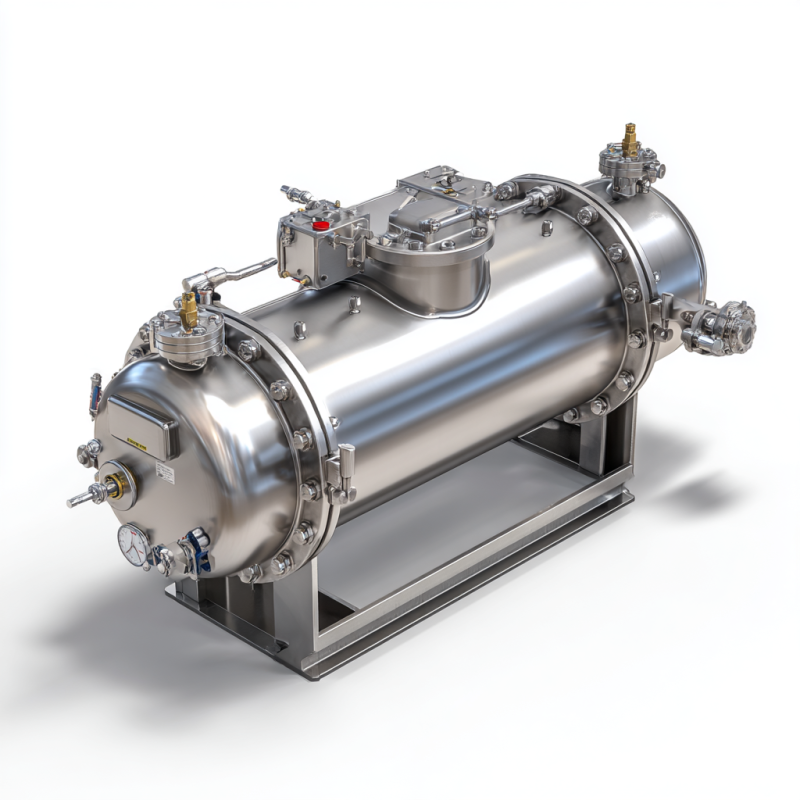

An industrial fuel water separator vessel removes water and contaminants from fuel to protect equipment, improve safety, and ensure consistent performance. Prefabrication makes these vessels even more reliable and cost-efficient. Understanding What Is an Industrial Fuel Water Separator Vessel An industrial fuel water separator vessel is a pressurized container designed to remove water, sediment, and […]

Why Use a Diesel Fuel Water Separator Vessel for Better Performance

A diesel fuel water separator vessel protects engines by removing water from fuel, preventing corrosion, and ensuring consistent performance. It improves efficiency, reduces downtime, and safeguards industrial operations. Understanding Why Use a Diesel Fuel Water Separator Vessel Wondering why use a diesel fuel water separator vessel? Installing one from Red River, enhances engine efficiency and […]

How Does a Diesel Pressure Vessel Separator Work? Red River LLC

A diesel pressure vessel separator removes water, debris, and impurities from diesel fuel by using pressure, baffles, and filters inside a sealed chamber. This process ensures cleaner fuel, extends engine life, and supports reliable industrial operations. Understanding How Does a Diesel Pressure Vessel Separator Work If you are curious about how does a diesel pressure […]

What Is a Diesel Pressure Vessel Filter Separator? Red River LLC

A diesel pressure vessel filter separator is essential for diesel fuel filtration, removing water, debris, and contaminants to protect engines and ensure efficient operation. Prefabricated solutions from Red River, often ASME-certified, provide reliable, high-quality performance for industrial and commercial fuel systems while reducing installation risks and maintenance downtime. Understanding What Is a Diesel Pressure Vessel […]

Understanding Failure Safety: Types, Examples, and Engineering Best Practices

Failure safety in engineering ensures that systems remain secure and functional—even when things go wrong. From fail-safe shutdowns and fault-tolerant backups to inherently safe designs and layered defenses, each method minimizes risk and protects lives. This guide breaks down the key types of failure safety, with real-world examples and best practices for industries like pressure […]

Regulation 5 for private water supplies: What Owners and Operators Need to Know

Regulation 5 for private water supplies sets the expectations for keeping private water systems safe, reliable, and fit for use. It focuses on risk assessment, ongoing monitoring, and prompt corrective action when issues appear. For industrial operators, the regulation also links water safety to the integrity of storage and process equipment, including pressure vessels. Red […]