Why is Metallurgical Failure Analysis Important Red River LLC

Metallurgical failure analysis identifies the causes of metal component failure and ensures critical equipment like pressure vessels meet safety and performance standards. By integrating this process into prefabrication and working with experts like Red River, industries can prevent costly failures, improve safety, and optimize long-term reliability. Understanding Why Is Metallurgical Failure Analysis Important Metallurgical failure […]

How is Metallurgical Failure Analysis Done by Red River LLC

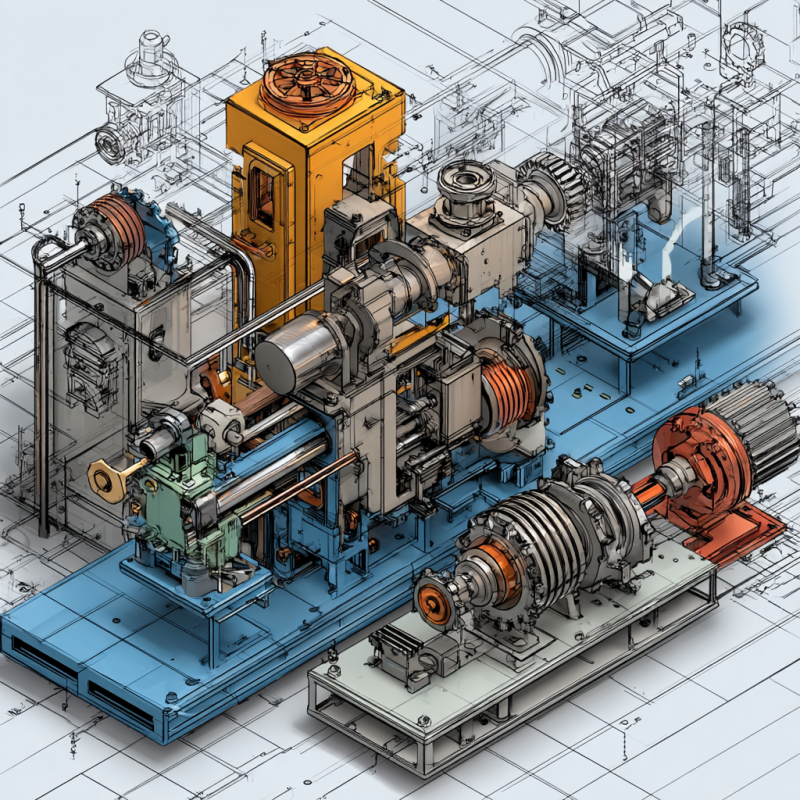

Metallurgical failure analysis uncovers why pressure vessels and industrial equipment fail by combining the metallurgical testing process, structured inspections, lab testing, and root cause analysis to guide design improvements. At Red River LLC, integrating software modeling and Lean Sigma principles with prefabrication ensures regulatory compliance, reduces hazards, and extends the service life of components while […]

What is Metallurgical Failure Analysis by Red River LLC

Metallurgical failure analysis investigates why metal components fail, using tests like visual inspection, chemical analysis, and mechanical evaluation. This process improves safety, reduces downtime, and ensures pressure vessel reliability by identifying root causes and preventing future failures. Understanding What is Metallurgical Failure Analysis in Industry Most metal structures play a vital role in industrial applications, […]

Why is Mechanical Failure Analysis Important in Industry?

Mechanical failure analysis is essential for preventing safety risks, costly downtime, and regulatory issues by identifying root causes like fatigue, corrosion, and design flaws. It enhances industrial safety, efficiency, and long-term reliability across sectors such as pressure vessels, energy, and manufacturing. Why is Mechanical Failure Analysis Important for Safety and Efficiency Mechanical failure can disrupt […]

How to Perform Mechanical Failure Analysis with Confidence

Mechanical failure analysis identifies root causes of equipment breakdowns through data collection, testing, and inspection. With Red River LLC’s expertise, you can improve safety, prevent recurrence, and ensure reliable, cost-efficient operations. Mastering How to Perform Mechanical Failure Analysis If you manage industrial equipment like pressure vessels or structural assemblies, you’ve likely wondered how to perform […]

What Is Mechanical Failure Analysis Explained

Mechanical failure analysis identifies root causes of breakdowns like material flaws, design errors, or corrosion to prevent costly downtime and improve reliability. For industries using pressure vessels, combining this process with prefabrication enhances safety, strengthens durability, and supports long-term efficiency. Understanding What Is Mechanical Failure Analysis in Industry What is mechanical failure analysis? Mechanical failures […]

What Are Common Pressure Vessel Failures | Red River LLC

Common pressure vessel failures are often caused by corrosion, fatigue, overpressure, material flaws, and operational missteps. By understanding these risks and implementing regular inspections, ASME compliance, and quality fabrication methods like prefabrication, you can avoid catastrophic incidents and extend equipment life. This guide outlines practical strategies to keep your pressure vessels safe, efficient, and compliant. […]

How to Perform Pressure Vessel Failure Analysis: Red River LLC

Understanding how to perform pressure vessel failure analysis involves a systematic review of design data, visual inspections, NDT, metallurgical testing, and stress assessments to uncover root causes of failure. By partnering with experts like Red River LLC and implementing rigorous quality control, you can reduce downtime, increase safety, and extend the life of your equipment. […]

What Causes Pressure Vessel Failure | Red River LCC

Understanding what causes pressure vessel failure is critical to preventing costly safety incidents and operational downtime. This guide explores the key failure triggers such as corrosion, material defects, and welding issues alongside analysis techniques and the benefits of prefabrication. Partnering with experts like Red River LLC ensures compliance, durability, and long-term system reliability. Exploring What […]

Why Pressure Vessel Explosions Occur and How to Prevent Them

Understanding the Causes of Pressure Vessel Explosions is vital for operational safety. Explosions often stem from overpressure, material failure, poor inspection or non‑compliance with pressure vessel safety standards and compliance. Regular maintenance, adherence to what are the safety standards for pressure vessels, and working with experienced professionals like RedRiver LLC help prevent catastrophic failures. Causes of […]