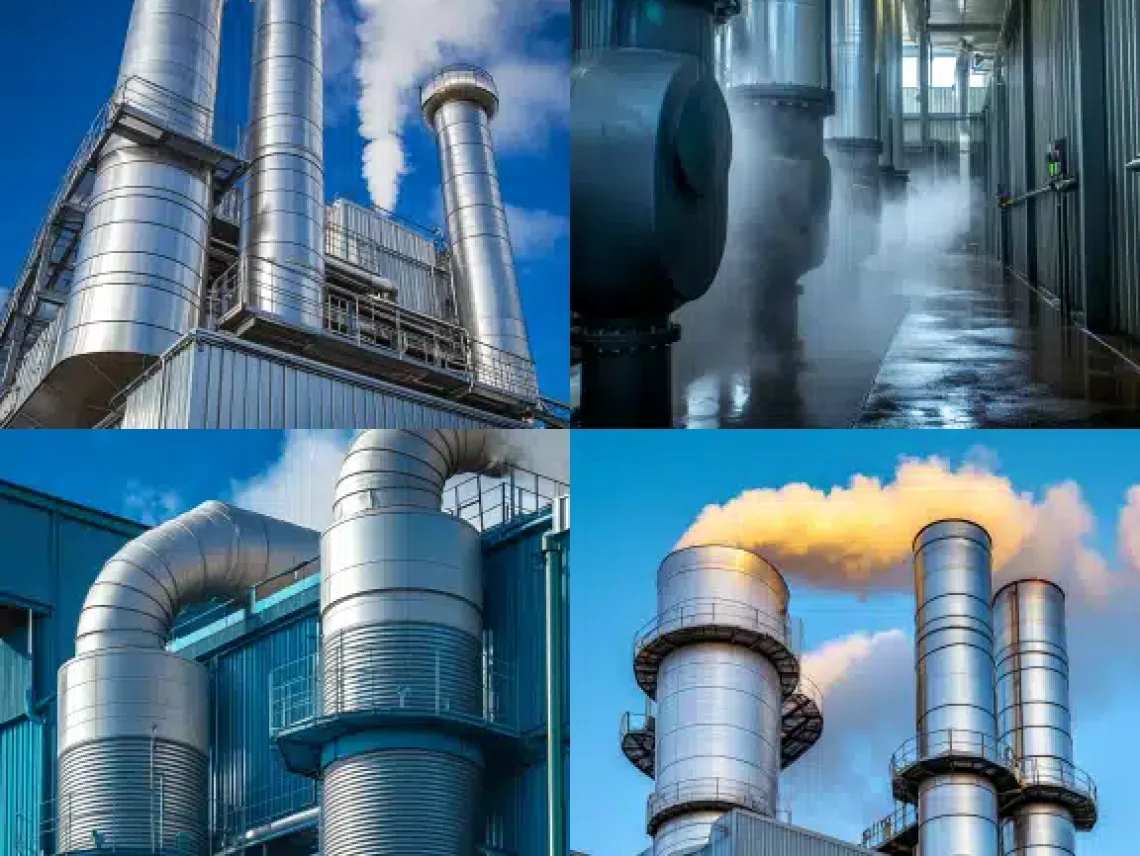

Wet and dry scrubbers are essential devices for controlling industrial air pollution. These systems play a crucial role in removing harmful particulate matter and gases from exhaust streams. Whether you’re dealing with sulfur dioxide, particulate matter, or other pollutants, scrubbers are the frontline solution. However, the use of scrubbers comes with challenges that industries must address to maximize their benefits while minimizing their environmental impact and operational costs. In this blog, we’ll delve into the primary challenges associated with wet scrubbers, explore the differences between wet and dry scrubbers, and discuss how industries can overcome these obstacles effectively.

One of the major drawbacks of wet scrubbers is their significant water consumption. Wet scrubbers rely on liquid mediums like water or chemical solutions to capture pollutants from gas streams. While highly effective, this reliance on water poses several challenges:

Operational Costs: The need for large volumes of water translates into high operational costs. Water procurement, treatment, and disposal can significantly impact the bottom line for industries. Companies must plan their budgets carefully to account for these expenses, especially in regions with water scarcity.

Environmental Impact: In areas where water is a limited resource, excessive water usage can create environmental challenges. Moreover, the discharge of untreated wastewater from scrubber operations can lead to contamination of water bodies, negatively impacting local ecosystems. According to ScienceDirect, efficient water management in industrial processes is critical for sustainability.

Maintenance and Monitoring: Managing water use in scrubbers requires constant monitoring and maintenance. Proper chemical dosing, pH control, and cleaning of components are necessary to ensure optimal performance and comply with environmental regulations.

While wet scrubbers are highly efficient at removing particulate matter, they are less effective for certain types of gases. This limitation can require industries to invest in additional equipment or opt for different scrubbing technologies, such as dry scrubbers. Explore the types of scrubbers for more insights on this topic.

The disposal of wastewater from wet scrubbers presents another challenge. This wastewater can contain pollutants that need to be treated before being released into the environment. Without proper treatment, industries risk contaminating local water supplies.

Despite the challenges, industries can implement various strategies to mitigate these issues and optimize the efficiency of wet scrubbers.

By implementing water recycling systems, industries can reduce fresh water consumption and minimize wastewater discharge. Reusing treated water in the scrubber system can significantly lower operational costs and reduce the environmental impact. Read more on evaluating the effectiveness of scrubbers in reducing emissions.

Fine-tuning scrubber parameters such as gas flow rates and liquid-to-gas ratios can optimize water usage. A more efficient scrubber design will ensure maximum pollutant removal while minimizing excess water consumption. Understanding the role of scrubbers in CO2 emission reduction is also crucial for improving scrubber efficiency. For additional information on optimizing scrubber designs and their role in air pollution control, check out this article from the EPA on managing air quality control strategies to achieve air pollution reduction.

For certain applications, dry scrubbers may offer a more effective solution. Dry scrubbers do not require water, and instead use dry sorbents like alkaline slurries to remove pollutants. This technology is particularly useful in facilities where water usage is restricted or where wastewater disposal is a concern. Learn more about how dry scrubbers are enhancing pollution control in specific industries.

To address the environmental impact, industries must ensure they are in compliance with local and national regulations on water use and pollutant discharge. Proper treatment and disposal of wastewater, in line with these regulations, will help mitigate any harmful effects on surrounding ecosystems.

While wet scrubbers are crucial for controlling industrial air pollution, they come with significant challenges, particularly related to water consumption and wastewater management. By adopting strategies like water recycling, optimizing scrubber design, and exploring alternative technologies like dry scrubbers, industries can reduce their environmental impact and improve operational efficiency. Scrubber systems play an essential role in reducing pollutants and helping businesses meet environmental regulations, but understanding and addressing their challenges is key to maximizing their effectiveness.

At Red River LLC, we specialize in the design and manufacturing of high-quality scrubber systems tailored to meet the unique needs of your facility. Whether you’re looking for wet or dry scrubber solutions, our team is here to help you navigate the challenges of industrial air pollution control. Contact us today to learn how we can assist with your air quality needs.

Wet scrubbers use water as a scrubbing medium to capture pollutants from exhaust gases. The volume of water required depends on factors like gas flow rate and pollutant concentration.

Industries can implement water recycling systems and ensure proper treatment of wastewater before discharge to minimize the environmental impact. You can read more about environmental considerations.

Wet scrubbers use water or liquid solutions to remove pollutants, while dry scrubbers use solid sorbents, such as lime or activated carbon, to capture contaminants without requiring water.

No, dry scrubbers are more suitable for certain pollutants, particularly acid gases. Wet scrubbers are more effective for removing particulate matter and water-soluble pollutants.

Yes, industries must comply with local and national regulations on water use and wastewater discharge to prevent environmental pollution.

Optimizing scrubber design parameters, such as gas flow rates and liquid-to-gas ratios, can significantly reduce water consumption and improve the efficiency of pollutant removal.

Dry scrubbers are effective for removing acid gases and particulate matter but are less effective than wet scrubbers for certain types of pollutants.

Wet scrubbers are highly effective at removing pollutants but come with challenges like high water consumption and wastewater disposal.

Water recycling systems can significantly reduce water usage and environmental impact.

Dry scrubbers offer a water-free alternative, especially for specific types of gases.

Optimizing scrubber design and operation can improve efficiency and minimize resource consumption.

Compliance with environmental regulations is essential for reducing negative environmental effects.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.