Design Conditions for Pressure Vessels: Key Considerations

Table of Contents

ToggleIntroduction to the Design conditions for a Pressure Vessel

Pressure vessels are crucial components in a wide range of industries, from oil and gas to chemical processing and power generation. These vessels are designed to safely contain and store fluids under varying pressure and temperature conditions. To ensure the integrity and safety of pressure vessels, engineers must carefully consider several design conditions. In this article, we will delve into the essential factors that influence the design of pressure vessels.

Safety Features: The Guardians of Pressure Vessel Integrity

Within the world of pressure vessel engineering, where precision meets the relentless forces of nature, safety features emerge as the unsung heroes. Pressure relief devices, including safety valves and rupture disks, stand as formidable guardians of pressure vessel integrity. Their purpose is clear and non-negotiable: to provide a fail-safe mechanism that ensures overpressure protection and prevents catastrophic failures. In the intricate dance of design, engineers are tasked with crafting these components to be not just functional but to excel in the role of safeguarding both the vessel and its surroundings.

The Vital Role of Pressure Relief Devices

Pressure vessels are subjected to fluctuating conditions, where the pressure within them can vary due to operational changes, process upsets, or unforeseen events. Without a means of releasing excess pressure, vessels can reach a critical breaking point, risking catastrophic failures with potentially devastating consequences. This is where pressure relief devices come into play.

Safety Valves: The Sentinels of Pressure Control

Safety valves are the stalwarts of overpressure protection. These devices are meticulously engineered to act as sentinels, guarding against the relentless march of pressure beyond safe limits. Their design includes a spring-loaded mechanism calibrated to open at a predetermined pressure threshold. When the vessel’s internal pressure exceeds this threshold, the safety valve springs into action, rapidly releasing excess pressure and preventing the vessel from reaching its breaking point.

Rupture Disks: The Emergency Pressure Relief

Rupture disks serve as the emergency release valves of pressure vessels. Unlike safety valves, they are non-reclosing devices, meaning that once they rupture, they must be replaced. Rupture disks are designed to burst at a specific pressure, providing an instantaneous and unobstructed path for excess pressure to escape. Their simplicity makes them effective fail-safe mechanisms, especially in situations where rapid pressure relief is critical.

Pressure and Temperature Conditions: The Foundation

The operating conditions of a pressure vessel are its foundational parameters. Engineers must consider the maximum and minimum pressures and temperatures that the vessel will encounter throughout its operational life. These conditions are not static; they can fluctuate, and the vessel’s design must accommodate these variations without compromising safety.

Stress Analysis: Distributing the Load

Pressure vessels are subjected to immense internal pressures. Engineers conduct stress analysis to ensure that the vessel’s structure can withstand these pressures without failing. The distribution of stress throughout the vessel’s components is carefully calculated, and factors such as stress concentrations and fatigue are meticulously addressed.

Geometry and Shape: Form Follows Function

The shape and geometry of a pressure vessel are not arbitrary. They are designed to optimize stress distribution, minimize weak points, and ensure efficient fluid flow. Common shapes include cylindrical, spherical, and elliptical vessels, each chosen for its specific advantages in stress management.

Material Thickness: Striking the Balance

The thickness of the vessel’s walls is a critical design consideration. It must be sufficient to withstand the calculated stresses while avoiding unnecessary weight and material costs. Engineers employ complex calculations to determine the optimal thickness for different sections of the vessel.

Corrosion Protection: Guarding Against Deterioration

Corrosion can be a silent but potent adversary. Engineers incorporate corrosion-resistant materials, coatings, and cathodic protection systems to safeguard the vessel’s integrity over time, especially when handling corrosive substances.

Regulatory Compliance: Meeting Industry Standards

Pressure vessels must adhere to industry-specific codes and standards, such as the ASME Boiler and Pressure Vessel Code. Compliance ensures that the vessel is designed and fabricated in a manner that meets established safety criteria.

Inspection and Testing: Ensuring Reliability

Throughout the vessel’s life cycle, rigorous inspections and testing are conducted. These include non-destructive testing (NDT) methods like ultrasonic testing, radiographic testing, and hydrostatic testing, all aimed at detecting defects and ensuring the vessel’s ongoing reliability.

Nozzle and Fitting Design: Ensuring Strength and Functionality

In the intricate world of pressure vessel design, where every detail matters and safety reigns supreme, nozzles, flanges, and fittings emerge as both essential components and potential points of vulnerability. These openings in the vessel serve as gateways for fluids, connecting it to the wider network of pipes, valves, and processes. However, their significance extends far beyond mere functionality. Engineers must embark on a nuanced journey of design, considering their size, shape, and location with meticulous care. The goal is twofold: to minimize stress concentrations and to ensure the smooth and efficient flow of fluids within the vessel.

Environmental Considerations

Pressure vessels used in outdoor or corrosive environments may require additional protective measures. This could involve coatings, insulation, or the use of specialized materials to withstand exposure to harsh weather conditions or corrosive substances.

In conclusion, designing pressure vessels involves a multifaceted approach that takes into account numerous design conditions, regulatory requirements, and safety considerations. Engineers must balance strength, durability, and operational efficiency to create vessels that can safely contain and transport fluids under various pressures and temperatures. Thorough analysis, careful material selection, and adherence to industry standards are essential to ensure the long-term integrity of pressure vessels in diverse industrial settings.

Need a reliable partner?

FAQ: Design Conditions for Pressure Vessels

1. What are the key factors to consider in the design of a pressure vessel?

When designing a pressure vessel, several critical factors must be considered to ensure safety and functionality. These include the operating pressure and temperature, the type of material to be contained, corrosion considerations, the environment in which the vessel will operate, and the standards and regulations applicable to the vessel’s design and use. Additionally, the vessel’s size, shape, and method of fabrication play crucial roles in its overall design.

2. How does the choice of material affect the design of a pressure vessel?

The material selection for a pressure vessel significantly impacts its design. Different materials have varying strengths, corrosion resistance, and temperature tolerances. For instance, carbon steel is commonly used for its strength and cost-effectiveness, but stainless steel might be preferred for its corrosion resistance. The chosen material must be compatible with the vessel’s intended contents and operating conditions while meeting the necessary safety standards.

3. What are the common standards and codes used in pressure vessel design?

Pressure vessel design is governed by various international and national standards to ensure safety and reliability. The most commonly referenced standards include the ASME Boiler and Pressure Vessel Code (BPVC) in the United States, the Pressure Equipment Directive (PED) in Europe, and the Standards Australia (AS) in Australia. These standards provide guidelines on the design, fabrication, testing, and certification of pressure vessels.

4. How do pressure and temperature considerations influence pressure vessel design?

The operating pressure and temperature are crucial in determining the thickness, shape, and material of the vessel’s walls. Higher pressures and temperatures require thicker walls and more robust materials to withstand internal stress. The design must account for the maximum expected operating conditions and potential fluctuations to ensure the vessel’s integrity under all circumstances.

5. What role does corrosion play in the design of pressure vessels?

Corrosion is a significant concern in pressure vessel design, especially when the vessel is used to store or process corrosive substances. The design must consider the type of corrosion (such as general, pitting, or stress corrosion cracking), the corrosive properties of the contents, and external environmental factors. Material selection, protective coatings, and corrosion allowances are common strategies to mitigate corrosion risks.

Solutions

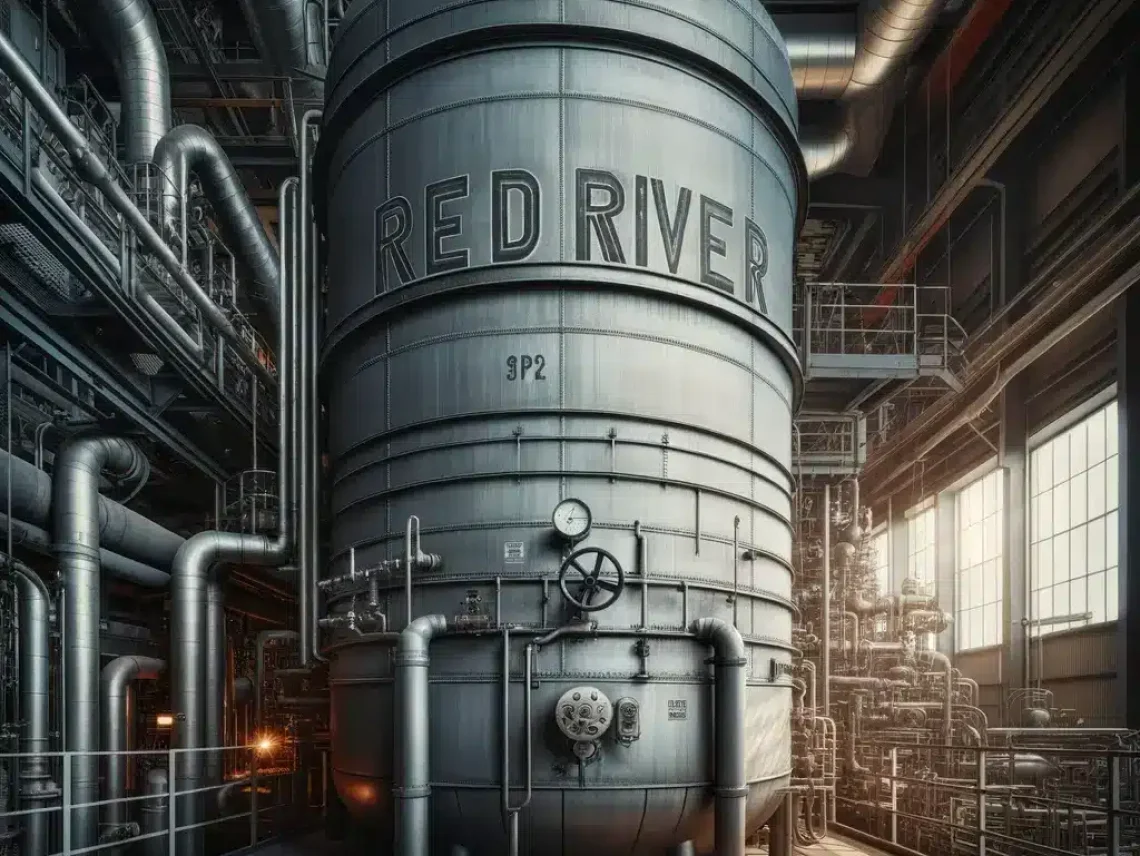

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Need action? Ready to Get Started?

We are here to make it happen. Request a quote!