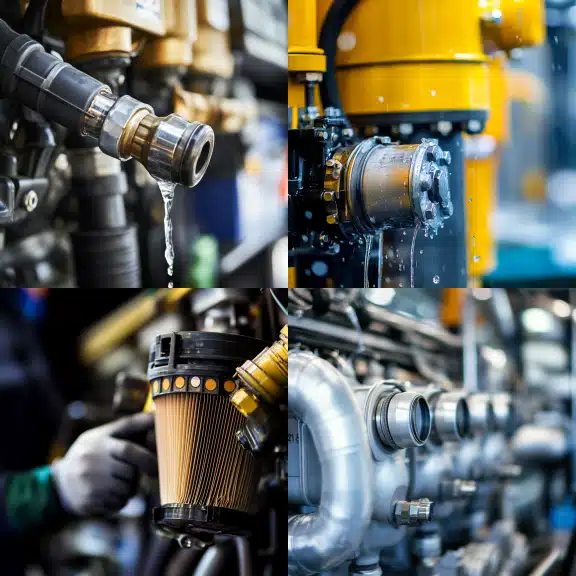

Water in diesel fuel can lead to severe engine damage. Diesel fuel filters are your first line of defense, especially when paired with a water separator. Regular maintenance and smart fuel handling practices help prevent water-related issues and keep your engine running efficiently.

Understanding the Importance of Diesel Fuel Filters in Preventing Water Contamination

Water contamination in diesel fuel systems is a significant threat to your engine’s health. Understanding how fuel filters diesel can prevent water damage is crucial for maintaining the longevity and performance of your diesel-powered equipment. This article explores the role of diesel fuel filters in water removal, the types of filters available, and how to choose the right one to protect your engine.

How Water Enters Diesel Fuel Systems

Water can enter diesel fuel systems in several ways:

- Condensation forming inside the fuel tank due to temperature changes.

- Rainwater seeping through a loose fuel cap.

- Low-quality fuel with high water content.

Water contamination can cause a range of problems, including injector damage, reduced engine efficiency, and even engine failure. Early detection and proper filtration are essential to prevent these issues.

The Role of Diesel Fuel Filters in Water Removal

Diesel fuel filters play a vital role in removing water before it reaches your engine. These filters separate water from fuel using various mechanisms, such as coalescing filters and hydrophobic filters. While coalescing filters allow small water droplets to combine into larger ones for easier removal, hydrophobic filters repel water and prevent it from mixing with the fuel.

How Effective Are Diesel Fuel Filters at Stopping Water?

The effectiveness of fuel filters diesel in blocking water depends on factors like filter design, the condition of the fuel, and the operating environment. Over time, even the best filters can become clogged, which reduces their ability to block water. Regular maintenance is key to keeping your fuel filter effective and your engine running smoothly.

A diesel fuel filter alone may not be sufficient in high-risk environments. In these cases, combining it with a dedicated water separator is a smart solution. A water separator works to remove larger water volumes before the fuel enters the filter. To learn more, check out our post on getting to know your fuel water separator.

Best Practices to Avoid Water in Diesel Fuel

Preventing water contamination begins with maintaining proper fuel storage and handling practices:

- Purchase fuel from reputable suppliers to reduce the risk of contamination.

- Regularly inspect fuel storage tanks for signs of water buildup.

- Keep fuel tanks full to minimize condensation, and seal caps tightly.

- Use fuel additives that help disperse water, allowing it to pass through the engine safely.

Additionally, it’s important to use filters with appropriate micron ratings and water drainage systems. For more on choosing the right fuel filter diesel, read our detailed guide on fuel water separators.

How to Maintain Diesel Fuel Filters for Maximum Water Protection

Proper maintenance ensures that your diesel fuel filters function effectively. Common signs that your filter needs attention include:

- Difficulty starting the engine.

- Reduced engine power.

- Excessive exhaust smoke.

Regular fuel filter diesel replacement, typically every 10,000 to 25,000 miles, or sooner in demanding conditions, will prevent water from bypassing the filter and entering the engine.

Picking the Right Diesel Fuel Filter for Your Needs

When selecting a fuel filter diesel, consider:

- Filter Type: Coalescing and hydrophobic filters offer excellent water removal capabilities.

- Micron Rating: A lower micron rating provides finer filtration, including better water removal.

- Built-in Water Drainage: Some filters come with a drain that alerts you when water has accumulated.

For more information, check out our post on understanding oil-water separators.

Protect Your Engine Here’s the Bottom Line

Water in your diesel fuel system is a preventable issue. By understanding how water enters your system, choosing the right fuel filter diesel, and maintaining regular filter replacement schedules, you can protect your engine from costly water damage. The right diesel fuel filters, combined with proper storage and fuel management practices, will keep your engine running at its best.

Safeguard Your Diesel Engine from Water Contamination

Maintaining a diesel engine free from water contamination is essential for long-term performance. By understanding the role of fuel filters diesel, choosing the appropriate filter, and following best maintenance practices, you ensure your diesel engine operates at optimal efficiency. Don’t neglect your fuel system, take action now to protect your equipment and minimize downtime.

Take the Next Step: Protect Your Diesel Engine with the Right Fuel Filters

While diesel fuel filters do a great job at water removal, many of them work best when combined with a dedicated water separator. A water separator is designed to remove larger amounts of water before the fuel reaches the filter. The key difference is that a water separator focuses more on separating water, while a diesel fuel filter handles particulates and small amounts of water. In environments where the risk of water contamination is high, a dedicated water separator should be used alongside a diesel fuel filter for ad

If you’re ready to take control of water contamination in your diesel systems, explore our range of high-performance diesel fuel filters. Contact Red River today to discuss the best filtration solutions for your equipment and get a customized recommendation.

Frequently Asked Questions

1.What happens if water gets into my diesel engine?

Water in your diesel engine can cause misfires, rust in the fuel system, injector damage, and, in extreme cases, engine failure. Regular maintenance and the right fuel filters diesel are crucial to prevent these issues.

2.How do I remove water from my diesel tank?

You can use fuel additives for small water amounts or drain the tank completely for larger contamination. Regular inspection of your fuel filters diesel and separators is essential.

3.How often should I replace my diesel fuel filter?

It’s recommended to replace your diesel fuel filter every 10,000 to 25,000 miles, depending on the operating conditions and fuel quality.

4.What is the difference between a fuel water separator and a diesel fuel filter?

A fuel water separator is designed to remove large amounts of water before the fuel enters the filter, while a diesel fuel filter primarily removes particulates and smaller amounts of water. Using both together provides the best protection.

5.Can fuel filters diesel improve fuel efficiency?

Yes, using high-quality fuel filters diesel helps prevent contaminants, including water, from reaching the engine. This leads to improved engine efficiency, better fuel economy, and reduced wear on engine components.

Key Takeaways

- Water contamination in diesel fuel causes injector damage, rust, and engine failure.

- Diesel fuel filters remove small amounts of water; water separators handle larger volumes.

- Sources of water include condensation, poor-quality fuel, and loose fuel caps.

Maintenance matters: Replace filters every 10,000–25,000 miles and inspect regularly. - Choose filters with coalescing or hydrophobic technology, and a micron rating fit for your environment.

- Combine proper storage, fuel additives, and trusted fuel suppliers to reduce risk.

Always act early—early detection = less damage and lower repair costs.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No subpillar set for this blog post.

About Author