Cryogenic Liquid Transportation is essential for safely moving extremely cold substances such as nitrogen, oxygen, and argon. This process requires specialized equipment, strict safety standards, and careful handling to maintain temperature integrity and prevent accidents. Different transportation modes—road, rail, maritime, air, and pipeline—offer unique advantages and challenges. Red River ensures high-quality solutions that adhere to safety standards, support compliance, and optimize efficiency in cryogenic logistics.

Safety Measures in Cryogenic Liquid Transportation

Various regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT), have established standards and policies for the safe transportation of cryogenic liquids. Consequently, compliance with these guidelines is mandatory to prevent accidents and ensure public safety.

Understanding Cryogenic Liquid Transportation

Cryogenic Liquid Transportation begins with ensuring that extremely low-temperature liquids are handled safely and efficiently. The process requires specialized tanks, rigorous safety protocols, and trained personnel to maintain the stability and integrity of the liquids throughout transit. Understanding the principles and practices behind Cryogenic Liquid Transportation is crucial for industries relying on precise delivery of cryogenic materials.

Key Principles of Cryogenic Liquid Transportation

- Maintaining consistent low temperatures to prevent vaporization

- Ensuring structural integrity of containers under extreme pressures

- Complying with regulatory standards and safety guidelines

- Implementing risk mitigation strategies to handle emergencies

Safety Measures in Cryogenic Liquid Transportation

Safety is paramount in Cryogenic Liquid Transportation. Organizations must comply with industry standards and regulatory requirements to prevent accidents. Effective safety measures include:

- Using insulated and pressure-resistant cryogenic tanks

- Training personnel to handle low-temperature liquids safely

- Incorporating monitoring systems for temperature and pressure

- Installing safety valves and emergency shutdown mechanisms

These measures align with Pressure Vessel Safety Standards and Compliance, ensuring that all handling procedures follow established protocols. Adhering to what are the safety standards for pressure vessels and the ASME code for pressure vessel safety is essential to protect personnel, equipment, and the environment.

Risk Mitigation Strategies for Transporting Cryogenic Liquids

Risk management is critical in Cryogenic Liquid Transportation. Key strategies include:

- Conducting thorough hazard assessments before transport

- Developing contingency plans for leaks or spills

- Regular inspection and maintenance of transport equipment

- Implementing strict handling and storage procedures

Following Pressure Vessel Inspection and Maintenance practices ensures that all cryogenic containers remain in optimal condition. Knowing how often do pressure vessels need to be inspected, how to inspect a pressure vessel, and what to include in a pressure vessel inspection checklist are vital steps in maintaining safety and efficiency.

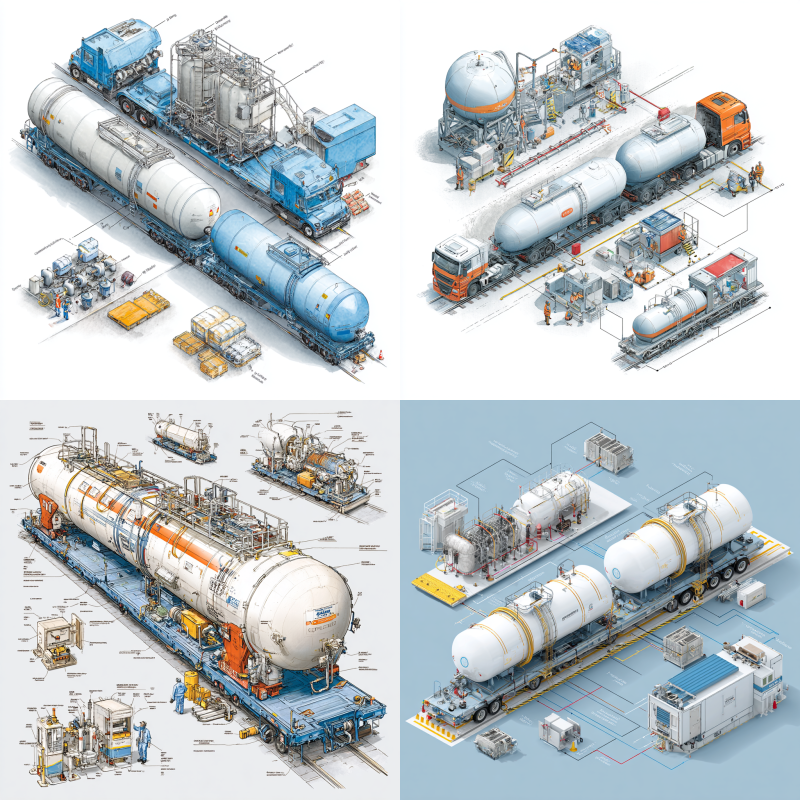

Different Modes of Cryogenic Liquid Transportation

Road Transportation

Road transport uses specially designed tanker trucks with cryogenic tanks to carry liquids like nitrogen, oxygen, and argon. Drivers and handlers must follow strict safety protocols to minimize risks during transit.

Rail Transportation

Rail transportation is cost-effective for moving large volumes over long distances. Specialized railcars maintain temperature control while adhering to regulatory standards, ensuring the safe delivery of cryogenic liquids.

Maritime Transportation

Maritime shipping handles global delivery of cryogenic liquids in large quantities. Cryogenic vessels are designed to withstand harsh ocean conditions while maintaining liquid integrity. Safety protocols include secure containment, leak prevention, and emergency preparedness.

Air Transportation

Air transport is used for urgent or smaller deliveries. Special packaging ensures that cryogenic liquids remain safe during flights. Personnel must follow strict procedures to maintain temperature and prevent accidents.

Pipeline Transportation

Pipeline systems offer a continuous, efficient method for transporting cryogenic liquids over land. Insulated and pressurized pipelines maintain liquid integrity and reduce the risk of leaks or temperature fluctuations.

Cryogenic Liquid Transportation

Cryogenic Liquid Transportation requires meticulous planning, specialized equipment, and adherence to stringent safety protocols. By following regulatory standards, implementing comprehensive risk mitigation strategies, and using the right transportation modes, industries can ensure safe and reliable delivery of cryogenic materials. Red River combines engineering expertise with safety-focused solutions to provide high-quality cryogenic transport systems.

Partner With Experts for Safe Cryogenic Liquid Transportation

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out today and experience the Red River difference.

Where American Made and American Values come together, we care more.

Visit: https://www.redriver.team/

Frequently Asked Questions

1. What safety precautions are essential when transporting cryogenic liquids?

Safety requires insulated, pressure-resistant containers, trained personnel, and monitoring systems for temperature and pressure. Emergency procedures, valves, and containment measures are also critical.

2. What are the main challenges in Cryogenic Liquid Transportation?

Challenges include maintaining low temperatures, preventing leaks or evaporation, ensuring personnel safety, and complying with regulatory standards throughout transit.

3. How do different transportation modes affect cryogenic liquids?

Road, rail, maritime, air, and pipeline systems each have unique safety, handling, and temperature control requirements. Equipment and procedures must adapt to each mode’s challenges.

4. What environmental concerns are associated with cryogenic liquids?

Leaks or spills can impact soil and water, potentially harming ecosystems. The energy-intensive production and transport of cryogenic liquids also contribute to carbon emissions.

5. How do regulatory requirements influence Cryogenic Liquid Transportation?

Standards set by authorities ensure container design, labeling, handling procedures, and emergency protocols meet strict safety and environmental guidelines.

6. How does pressure vessel inspection relate to cryogenic transport safety?

Regular inspections identify wear, leaks, or structural weaknesses, ensuring tanks comply with Pressure Vessel Safety Standards and Compliance and operate safely during transit.

7. What are the common materials used in cryogenic transport containers?

High-strength alloys and specialized metals are used for their durability, thermal resistance, and ability to maintain liquid integrity at extremely low temperatures.

8. How do emergency response plans improve safety?

Having well-defined contingency plans reduces risk during accidents or leaks, ensuring rapid, safe action to protect personnel and the environment.

Key Takeaways

- Cryogenic Liquid Transportation requires strict adherence to safety protocols and standards.

- Specialized containers and materials maintain temperature integrity and reduce risk.

- Different transportation modes present unique challenges that require customized handling strategies.

- Regular inspection and maintenance support long-term safety and reliability.

- Red River provides expert solutions for safe, efficient, and compliant cryogenic transport.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author