Your One‑Stop Solution for Precision Metalwork, Tailored to Fit Any Industry

When you need more than off‑the‑shelf solutions, bespoke metal fabrication delivers tailored parts engineered to your exact specifications. Unlike standard metal fabrication, which follows uniform templates, bespoke fabrication emphasizes custom design, prototyping, and precision execution—often with CAD‑driven processes and one‑off production runs.

What Makes Bespoke Fabrication Stand Out

- Custom Design & Prototyping

Every project begins with CAD modeling and prototyping to guarantee the final product aligns with performance, durability, and aesthetic criteria. - Specialized Techniques & Materials

Techniques such as laser, plasma, and waterjet cutting comparisons offer insights into how each method suits different materials and product needs - Industry‑Specific Solutions

Sectors like aerospace require exacting standards explore the importance of precision fabrication in aerospace

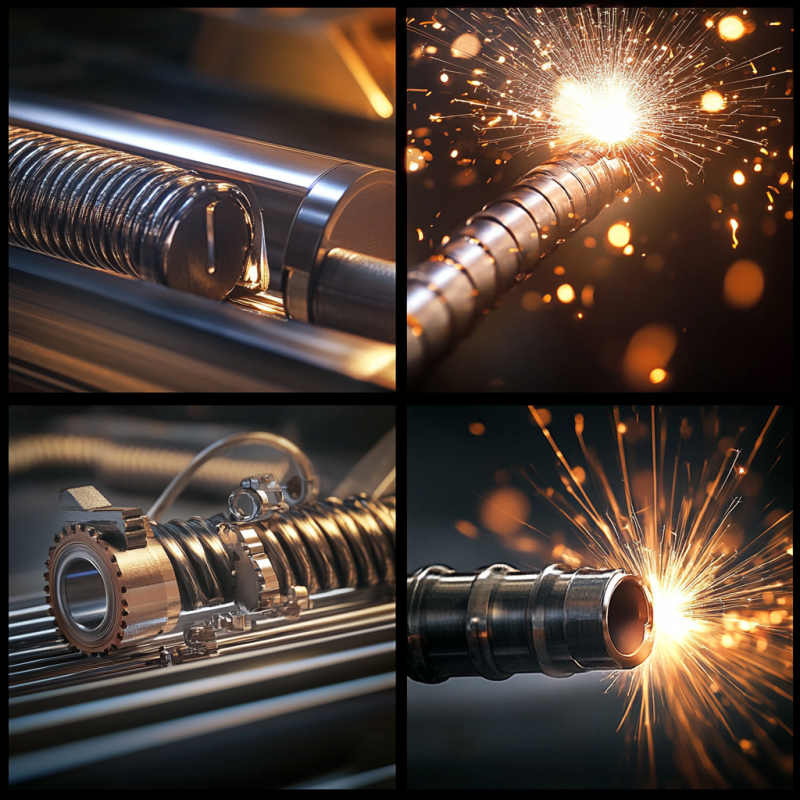

Core Metal Fabrication Techniques at Work

- Cutting: Achieve exact shapes using laser, plasma, or waterjet cutting—and learn how they stack up in terms of precision and application

- Forming & Joining: Processes like bending, rolling, welding, and brazing reshape and unite parts—see how they pair with achieving strength and tailored design.

Deepen your knowledge with our article on cutting, folding, and welding processes: Red River’s techniques breakdown.

Bespoke vs Standard Fabrication: A Side‑by‑Side Comparison

| Aspect | Standard Fabrication | Bespoke Fabrication |

|---|---|---|

| Design Approach | Predefined templates | Custom CAD‑based designs |

| Production Volume | High‑volume or repeat runs | One‑off or low‑volume, client‑specific |

| Materials Used | Common metals (e.g., standard steel) | Specialized alloys tailored to the use case |

| Precision Level | Adequate | Exceptional—tight tolerances required |

| Typical Applications | General manufacturing | Aerospace, medical, architectural design |

Real‑World Applications & Technical Context

- In aerospace, bespoke components must balance weight, strength, and precision—learn more about fabrication standards and compliance in this field.

- In medical devices, biocompatibility and micro‑tolerances are non‑negotiable bespoke delivery allows for tailored outcomes.

- Architectural elements often require artistry and durability; we’ve crafted solutions in our art and science of metal fabrication guide.

Elevating Engineering Through Tailored Craftsmanship

- Bespoke metal fabrication is a collaborative journey starting with your concept and ending in a high-precision, custom-engineered component. At Red River, we bridge design and execution, delivering unmatched quality in every bespoke project.

Ready to Bring Your Project to Life?

Let’s collaborate—whether you’re envisioning pressure vessels, skid packages, or complex bespoke parts, Red River Team has the skills and craftsmanship to exceed expectations. Reach out for a custom quote today.

Frequent Ask Question

1. What is bespoke metal fabrication?

Sheet metal fabrication is the process of cutting, shaping, and assembling flat sheets of metal into functional components or finished products.

2.How does it differ from standard fabrication?

Bespoke fabrication uses CAD-based design and tailored processes for singular, high-precision outcomes; standard fabrication follows universal patterns suited for bulk production.

3. Which industries benefit most from bespoke fabrication?

Sectors like aerospace, medical devices, and architectural design rely on bespoke solutions for precision and functionality.

4. How do cutting methods differ in bespoke projects?

Each method—laser, plasma, waterjet—has unique strengths. Learn which suits your needs in this comparison: laser vs. plasma vs. waterjet.

5. Are all three types of metal fabrication used in one project?

Yes, many fabrication projects combine cutting, forming, and joining to achieve the final product.

6. How do I choose the right metal fabrication process?

The choice depends on factors like material type, thickness, design complexity, and production volume.

7. Is metal fabrication dangerous?

Proper safety measures and equipment are essential, as fabrication often involves sharp tools, heat, and heavy machinery.

8. Can metal fabrication be automated?

Yes, many fabrication techniques use automated machinery like CNC lasers and robotic welders to increase precision and efficiency.

9. Where can I learn more about metal fabrication processes?

Industry websites, technical courses, and companies like Red River Team offer valuable resources and services.

Key Takeaways

- Bespoke metal fabrication means customized precision, not replicable templates.

- It enables you to realize designs that demand tight tolerances and specialized materials.

- Industries like aerospace, medical, and architectural sectors require and benefit from bespoke engineering.

- Mastering cutting, forming, and joining is critical for bespoke quality.

- Red River Team delivers excellence from design concept through to custom fabrication.

Related Blog Post

Marine-Grade vs Standard Stainless Steel

Pros and Cons of Vertical Integration

How to Dry Desiccant Properly and Regain Its Effectiveness

Why Do Gas Turbines Need Fuel Water Separator Vessels, Red River

How Does a Gas Turbine Fuel Water Separator Vessel Work

No related articles found.