Understanding Offshore Vessels in the Maritime Industry

Table of Contents

ToggleIntroduction to the Meaning of Vessel in Offshore

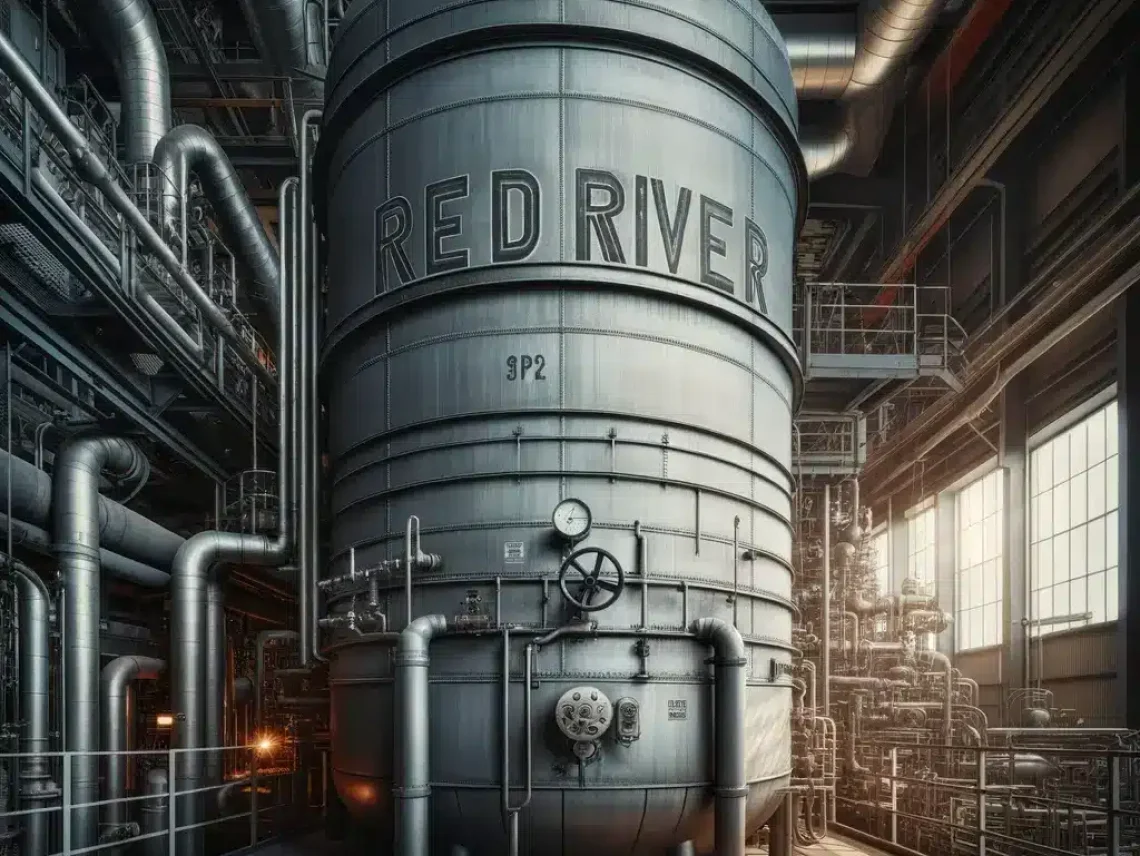

Offshore support vessels are the unsung heroes of the sea, playing a pivotal role in the success of offshore exploration, development, and maintenance. These specialized maritime vessels are engineered to perform a multitude of tasks, ranging from the transportation of goods and personnel to the execution of high-precision construction tasks in the challenging offshore environment. At Red River, we craft pressure vessels with the same dedication and precision that these mighty offshore vessels are built upon, ensuring that every project we undertake is supported by equipment you can trust.

The Evolution of Offshore Vessels in the Maritime Sector

The maritime sector has witnessed a significant evolution in the capabilities of offshore vessels. From the early days of simple transportation to the modern era of sophisticated service vessels, the industry has seen a leap in technological advancements. Red River LLC has paralleled this growth within the pressure vessel manufacturing domain, continuously innovating to meet the ever-evolving needs of offshore operations. Our vessels are built to withstand the rigors of the sea, just as our pressure vessels are designed to meet the stringent demands of various industries, including oil and gas, power generation, and biogas.

Why Offshore Vessels are a Cornerstone of Marine Engineering

Understanding offshore construction vessels and their functions is crucial to appreciating their role in marine engineering. These vessels are equipped to handle the toughest tasks in the most unforgiving environments. Similarly, Red River LLC’s pressure vessels are the cornerstone of countless operations, providing the resilience and reliability that our clients’ projects require. Our commitment to American values like hard work, innovation, and quality craftsmanship ensures that each pressure vessel we manufacture not only meets but exceeds the expectations of our clients.

Types of Offshore Support Vessels (OSVs)

Platform Supply Vessels (PSVs) Explained

PSVs are the lifeline to offshore platforms, delivering essentials with precision—a trait we emulate in crafting our pressure vessels.

The Functionality of Anchor Handling Tug Supply (AHTS) Vessels

AHTS vessels boast strength and versatility, much like Red River’s pressure vessels, designed for multifaceted industrial use.

Dive Support Vessels (DSVs) and Their Importance

DSVs ensure subsea operations’ safety and efficiency, reflecting our commitment to reliability in pressure vessel manufacturing.

Emergency Response and Rescue Vessels (ERRVs)

ERRVs are the vigilant guardians of the sea, ready to respond—a quality of dependability Red River upholds in every project.

Offshore Construction Vessels for Engineering Projects

These vessels are the floating factories of the sea, paralleling the complex engineering of Red River’s pressure vessels.

Offshore Service Vessels and Their Operations

Crew Transfer Vessels (CTVs) for Offshore Personnel

CTVs transport crews safely across the waves, mirroring the secure and robust design of our pressure vessels.

CTVs transport crews safely across the waves, mirroring the secure and robust design of our pressure vessels.

Offshore Processing Vessels for Oil and Gas

Processing vessels are the floating pioneers in oil and gas, akin to Red River’s innovative approach to pressure vessel design.

The Use of Seismic Vessels in Exploration

Seismic vessels, with their deep-sea mapping capabilities, reflect our drive for precision and excellence in manufacturing.

Inspection, Maintenance, and Repair Vessels (IMR)

IMR vessels maintain the integrity of offshore operations, much like our commitment to quality and durability in pressure vessel production.

The Design and Features of Specialized Maritime Vessels

Dynamic Positioning Systems in Modern Offshore Vessels

Dynamic positioning systems exemplify the cutting-edge technology we apply in the design and manufacture of our pressure vessels.

Innovations in Offshore Vessel Safety and Efficiency

Safety and efficiency are paramount in offshore vessels, as they are in Red River’s manufacturing processes.

The Impact of Technology on Offshore Vessel Navigation

Technological advancements in navigation enhance safety and precision, qualities that Red River ensures in its pressure vessels.

Offshore Vessels in the Oil and Gas Industry

The Critical Role of Drilling Vessels

Drilling vessels are key to exploration, just as Red River’s pressure vessels are to industrial operations.

Floating Production, Storage, and Offloading (FPSO) Units

FPSOs represent innovation and flexibility in offshore oil and gas, values that Red River champions in its manufacturing.

Offshore Tenders and Their Use in Deepwater Drilling

Offshore tenders support deepwater drilling, similar to how our pressure vessels support critical industrial processes.

The Economic Impact of Offshore Vessels

Job Creation and the Offshore Vessel Sector

The offshore vessel sector is a significant job creator, much like the employment opportunities provided by Red River.

The Global Offshore Vessel Market Overview

The global reach of the offshore vessel market reflects Red River’s expansive vision in pressure vessel manufacturing.

How Offshore Vessels Contribute to Energy Independence

Offshore vessels contribute to energy independence, paralleling Red River’s commitment to empowering industries through reliable pressure vessel solutions.

Safety and Regulations for Offshore Vessels

International Maritime Organization (IMO) Standards for Vessels

The IMO sets global standards for the safety, security, and environmental performance of international shipping. Red River’s pressure vessels are crafted with these high standards in mind, ensuring global compliance and safety.

Safety Procedures and Protocols on Offshore Vessels

Robust safety procedures are vital aboard offshore vessels, paralleling Red River’s commitment to the highest safety protocols in pressure vessel production.

Environmental Regulations Impacting Offshore Operations

Environmental regulations are shaping offshore operations, a consideration integral to Red River’s eco-conscious approach to pressure vessel manufacturing.

Offshore Vessels and Environmental Sustainability

Advances in Eco-Friendly Offshore Vessel Design

Innovations in offshore vessel design for environmental sustainability mirror Red River’s pursuit of eco-efficiency in manufacturing.

The Role of Offshore Vessels in Environmental Protection

Offshore vessels play a crucial role in protecting our oceans, akin to Red River’s commitment to environmental stewardship in pressure vessel production.

Reducing Carbon Footprint in Offshore Vessel Operations

Efforts to reduce the carbon footprint in offshore operations resonate with Red River’s eco-friendly manufacturing processes.

The Future of Offshore Vessels

Trends Shaping the Future of Offshore Vessel Design

Emerging trends in vessel design, focusing on automation and efficiency, are akin to Red River’s innovative manufacturing techniques.

The Role of Autonomous Vessels in Offshore Operations

The advent of autonomous vessels in offshore operations reflects Red River’s embrace of cutting-edge technology in pressure vessel manufacturing.

Renewable Energy and the Next Generation of Offshore Vessels

The integration of renewable energy in offshore vessels aligns with Red River’s vision for sustainable manufacturing solutions.

Choosing the Right Offshore Vessel for Your Project

Factors to Consider When Selecting an Offshore Vessel

Key considerations in vessel selection mirror the careful attention Red River gives to each custom pressure vessel project.

Red River LLC’s Fleet of Advanced Offshore Vessels

Red River boasts a fleet of advanced vessels, reflecting our commitment to innovation and quality in every pressure vessel.

Custom Offshore Solutions by Red River LLC

Red River’s custom solutions ensure that your offshore vessel meets specific operational needs, just as our pressure vessels are tailored to your specifications.

Need a reliable partner?

FAQ: Pressure Vessels in Offshore Operations

What are the unique challenges of manufacturing pressure vessels for offshore use?

Offshore pressure vessels must withstand harsh marine environments, including high salinity, humidity, and variable temperatures, which can lead to corrosion and material degradation. They also need to comply with rigorous safety and environmental regulations due to their critical role in offshore operations. The design and manufacturing process must consider these factors to ensure durability, safety, and compliance with international standards such as those set by the American Society of Mechanical Engineers (ASME) and the International Maritime Organization (IMO).

How does the design of offshore pressure vessels differ from standard industrial pressure vessels?

Offshore pressure vessels are typically designed with more robust materials and corrosion-resistant coatings to combat the harsh marine environment. They often feature specialized designs such as spherical shapes for better weight distribution and stability at sea. Additionally, offshore vessels may incorporate advanced safety features like emergency shutdown systems and remote monitoring capabilities to ensure safe operation in the less accessible and more challenging offshore environment.

What materials are commonly used in the construction of offshore pressure vessels, and why?

Common materials include high-strength carbon steel, stainless steel, duplex stainless steel, and sometimes exotic alloys like Inconel or Monel. These materials are chosen for their strength, durability, and resistance to the corrosive marine environment. The selection of material also depends on the specific contents of the vessel, operating temperatures, and pressures, as well as the vessel’s intended service life.

Can offshore pressure vessels be repaired or must they be replaced after damage?

Offshore pressure vessels can often be repaired, depending on the extent and type of damage. Repairs must be carried out under strict regulatory compliance to ensure the integrity of the vessel is restored. For minor damages, techniques such as welding or applying corrosion-resistant cladding can be used. However, if the vessel’s structural integrity is compromised, or if it’s more cost-effective, replacement might be the safer and more reliable option.

What are the latest technological advancements in offshore pressure vessel manufacturing?

Technological advancements include the use of automation and robotics in the welding and fabrication process, which enhances precision and efficiency. The integration of smart sensors and IoT (Internet of Things) technology for real-time monitoring and predictive maintenance is also on the rise. Additionally, advancements in material science have led to the development of new alloys and composite materials that offer superior performance in offshore conditions.

Table of Contents

ToggleRelated Blog Post

- Is a Boiler a Vessel?

- Is an Oil Rig a Vessel?

- What is an Example of a Pressure Vessel

- What is the Purpose of a Vessel?

- What are the 4 parts of a vessel?

- What is a Pressure Vessel in a Boiler?

- What is a Vessel in the Supply Chain?

- What is the difference a vessel and a pressure vessel?

- How does a pressure vessel work?

- What is the Difference Between a Boiler and a Vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Need action? Ready to Get Started?

We are here to make it happen. Request a qoute!