Understanding Pressure Reactors with Red River LLC

Table of Contents

ToggleIntroduction to Pressure Reactors

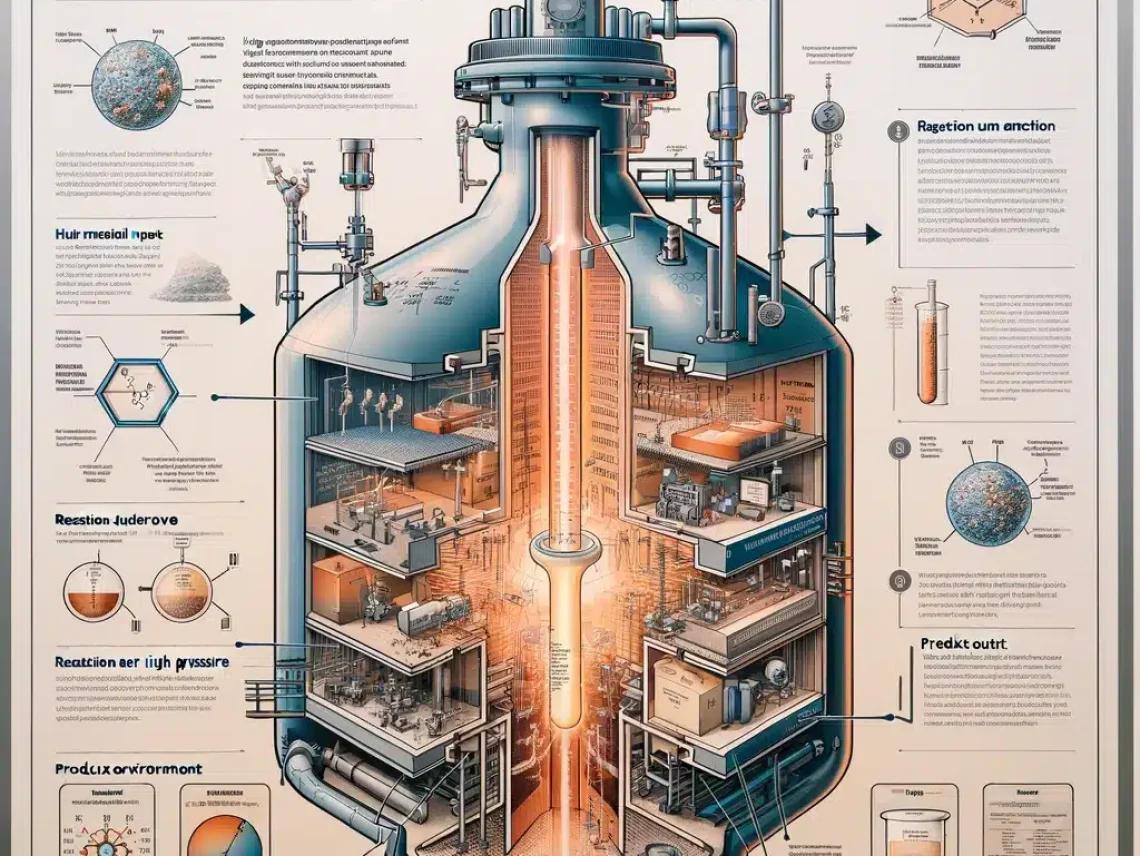

A pressure reactor, often referred to as a high-pressure reactor, is a specialized vessel designed to contain and manage chemical reactions under elevated pressures. These reactors are pivotal in various industries, from oil and gas to power generation, as they allow for enhanced reaction rates and product yields. The unique environment inside a pressure reactor can significantly influence the outcome of a reaction, making it a vital tool for many chemical processes.

Importance of pressure reactors in the industry

In today’s fast-paced industrial landscape, pressure reactors have become indispensable. They play a crucial role in sectors such as:

- OIL AND GAS: For refining processes and petrochemical synthesis.

- COMMERCIAL/PUBLIC WORKS: In waste management and water treatment facilities.

- POWER GENERATION: Especially in nuclear reactors where pressure containment is vital.

- MINERALS/ELEMENTS: In the extraction and processing of essential minerals.

- BIO GAS: For the production of sustainable energy sources.

Their ability to operate under controlled high-pressure conditions means reactions can be optimized for efficiency, yield, and quality. This not only boosts productivity but also ensures that industries can meet the ever-growing demands of our society.

Red River's expertise in pressure reactor technology

At Red River LLC, we pride ourselves on our deep understanding of pressure reactor mechanisms and our commitment to American values. Our roots are firmly planted in the morals, work ethic, and reputation that have shaped this great nation. We’re here for the doers, the innovators, and the blue-collar tradesmen who make America what it is today.

Our clients, ranging from international giants to budding startups, trust us with their most valuable projects. Why? Because at Red River, we don’t just deliver a product; we deliver an experience. Our involvement spans from the initial concept to the final startup, ensuring that our client’s visions are realized to perfection.

Our dedication to safety is unparalleled. We understand the science behind pressure reactors and the potential risks involved. That’s why we’ve embedded safety deep within our company culture, ensuring that every project we undertake meets the highest safety standards.

When you partner with Red River LLC, you’re not just getting a product; you’re getting the combined expertise, dedication, and passion of an entire team. Led by industry veteran Reilly Sasse, we ensure that every pressure reactor we manufacture is a testament to our commitment to excellence.

So, if you’re looking to understand the inner workings of a pressure reactor or seeking a partner who values your needs as much as you do, look no further. Red River LLC is here to guide you every step of the way. Give us a call, and let’s build the future together.

Pressure Reactor Functioning Principles

Basic components of a pressure reactor

A pressure reactor comprises several essential components, including the reactor vessel, agitator, heating or cooling system, and pressure relief devices. Each part plays a crucial role in ensuring efficient and safe operations.

The role of pressure in reactor operations

Pressure directly impacts reaction rates. By increasing the pressure, molecules are forced closer together, enhancing the likelihood of collisions and, consequently, the reaction rate.

Temperature and pressure: The dynamic duo

Together, temperature and pressure dictate the reactor’s environment. While pressure accelerates reactions, temperature controls the kinetic energy of molecules, influencing reaction outcomes.

The Science Behind Pressure Reactors

Chemical reactions under pressure

Under elevated pressures, certain reactions that are otherwise unfeasible become possible, opening doors to novel products and pathways.

Safety measures in high-pressure environments

Safety is paramount. Implementing pressure relief systems, robust vessel materials, and continuous monitoring ensures reactions remain controlled.

Innovations and advancements in reactor design

Modern reactors boast enhanced efficiency, safety features, and adaptability, thanks to continuous research and technological advancements.

Working of a High-Pressure Reactor System

Stages of operation

From initial charging to product extraction, a reactor undergoes various stages, each critical to the overall process.

Monitoring and control mechanisms

Sophisticated sensors and control systems maintain optimal conditions, ensuring consistent product quality.

Maintenance and troubleshooting

Regular maintenance and swift troubleshooting are vital for reactor longevity and operational efficiency.

Pressure Reactor Applications

Industries relying on pressure reactors

From petrochemicals to pharmaceuticals, numerous industries harness the power of pressure reactors for their processes.

Breakthroughs enabled by pressure reactor technology

Innovative products and sustainable solutions have emerged, all thanks to the capabilities of modern pressure reactors.

Real-world case studies from Red River LLC

Red River LLC has empowered industries with tailored reactor solutions, driving success stories across sectors.

Basics of Pressure Reactor Technology

Materials and construction

Pressure reactors are crafted from robust materials like stainless steel or special alloys, ensuring durability under extreme conditions. Their construction is meticulously designed to withstand high pressures and temperatures.

Pressure reactor vs. other reactor types

While other reactors operate under ambient conditions, pressure reactors are unique in their ability to handle elevated pressures, making certain reactions more feasible and efficient.

Enhancing reactor efficiency

Incorporating advanced agitation systems, optimized heating/cooling mechanisms, and digital monitoring tools can significantly boost a reactor’s performance.

Pressure Reactor Safety and Compliance

Safety protocols and best practices

Safety is paramount. Implementing pressure relief systems, regular inspections, and employee training ensures a hazard-free environment.

Regulatory standards and certifications

Pressure reactors adhere to stringent standards like ASME, ensuring their reliability and safety in industrial applications.

Red River's commitment to safety

At Red River LLC, safety isn’t just a protocol; it’s a core value. We prioritize creating a safe workspace, emphasizing continuous improvement and employee empowerment.

The Future of Pressure Reactors

Emerging trends and technologies

With advancements in AI and IoT, modern pressure reactors are becoming smarter, more autonomous, and more efficient.

Sustainability and environmental considerations

The future beckons reactors that are not only efficient but also environmentally friendly, minimizing waste and energy consumption.

Red River's vision for the future

Red River LLC envisions a world where pressure reactors drive innovation, sustainability, and growth, and we’re at the forefront of this evolution.

Need a reliable partner?

FAQ: Understanding Pressure Vessel Technology

What is the primary function of a pressure reactor?

A pressure reactor, also known as a high-pressure reactor, is designed to conduct chemical reactions under elevated pressures. This environment allows for enhanced reaction rates and yields, making certain chemical processes more efficient and feasible than they would be under standard atmospheric conditions.

How do pressure reactors differ from standard reactors?

While standard reactors operate under ambient or atmospheric conditions, pressure reactors are specifically designed to handle elevated pressures. This capability allows them to influence the outcome of chemical reactions in ways standard reactors can’t. For instance, some reactions that might be slow or even impossible at atmospheric pressure can be accelerated or made feasible in a pressure reactor.

Why is the material construction of a pressure reactor so crucial?

The materials used in constructing a pressure reactor need to withstand the high pressures and temperatures inside the vessel. Typically, robust materials like stainless steel or special alloys are used. The right material ensures the reactor’s durability, safety, and efficiency, especially during extreme conditions.

How do temperature and pressure work together in a reactor?

Temperature and pressure are closely interlinked in a reactor environment. While pressure can increase the rate of a reaction by forcing molecules closer together, temperature controls the kinetic energy of these molecules. By manipulating both factors, scientists and engineers can optimize reaction outcomes, influencing factors like speed, product yield, and quality.

Are there specific safety concerns associated with pressure reactors?

Yes, due to the elevated pressures they operate under, pressure reactors come with unique safety concerns. There’s a risk of explosion or rupture if the pressure inside the vessel exceeds its design limits. That’s why these reactors are equipped with safety features like pressure relief systems. Regular inspections, maintenance, and adherence to safety protocols are crucial to ensure the safe operation of pressure reactors.

Table of Contents

ToggleRelated Blog Post

- What type of reactor is HPC?

- Is a reactor a pressure vessel?

- What is column pressure vessel?

- How thick is a reactor pressure vessel?

- What are reactor pressure vessels made out of?

- How much does a reactor pressure vessel cost?

- Who is the manufacturer of reactor pressure vessel?

- What does a closed pressure vessel use to generate steam?

- What are the different types of pressure vessels in reactors?

- What is the purpose of a pressure vessel on a surface pumping system?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Need action? Ready to Get Started?

We are here to make it happen. Request a qoute!