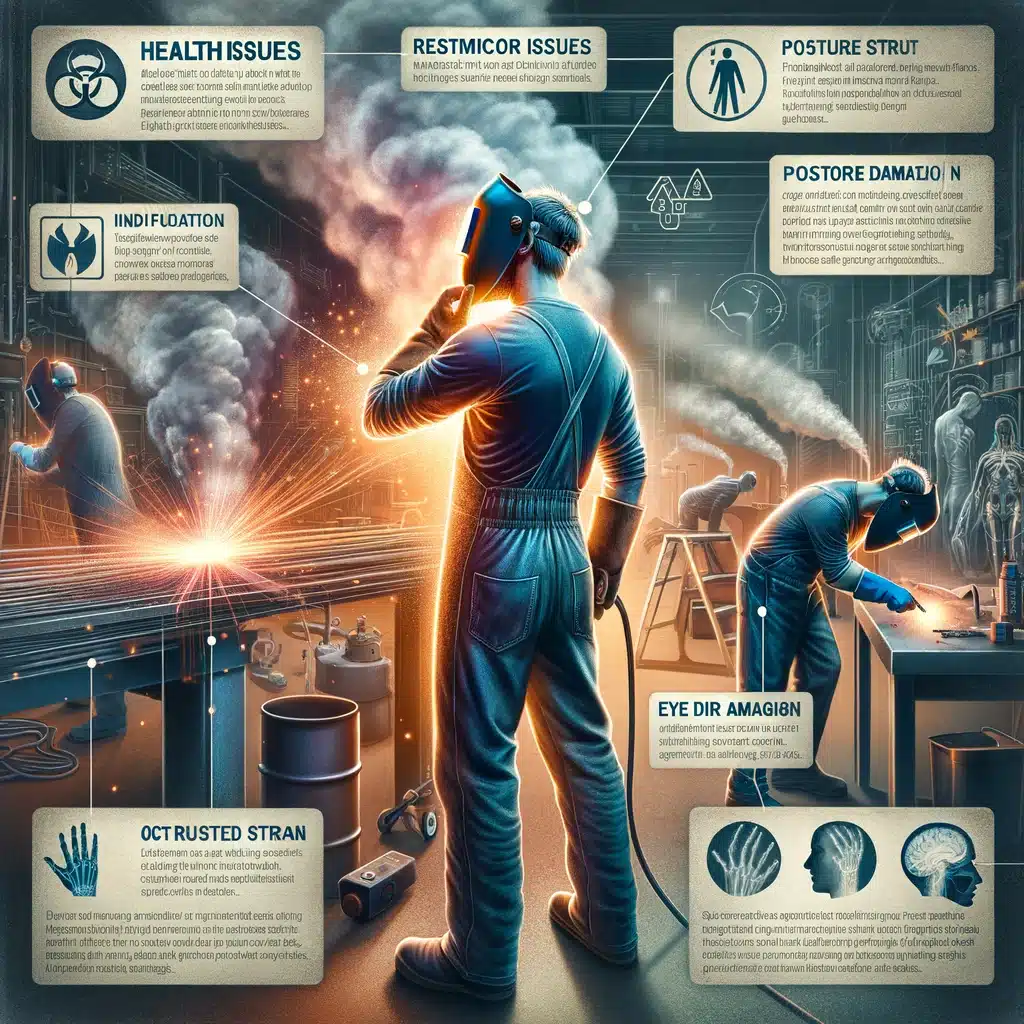

Understanding the Health Risks in Welding – A Comprehensive Guide

Introduction to Welding Health Risks

Welding isn’t always only a manner; it is an artwork and a technology that is pivotal in constructing the infrastructure of our society. From the sturdy structures in business and public works to the problematic designs in minerals and elements processing, welding is at the coronary heart of industrial innovation. At Red River, we see welding as a key aspect in our quest to supply challenging and impactful tasks. Our welders are not simply employees; they are craftsmen and innovators, playing a crucial function in shaping the future.

Why Discussing Welder's Health is Crucial?

In our journey, we’ve discovered that the health of our welders is synonymous with the fitness of our business. Addressing capability health risks for expert welders isn’t always just a regulatory requirement; it is an ethical duty. We’re speaking about actual human beings, with households and desires, who face ordinary occupational hazards. From respiratory health worries due to publicity to fumes and gases to the lengthy-term consequences on their eyes pores and skin, the fitness-demanding situations in welding careers are several and extensive.

Common Welding Health Risks Faced by Welders

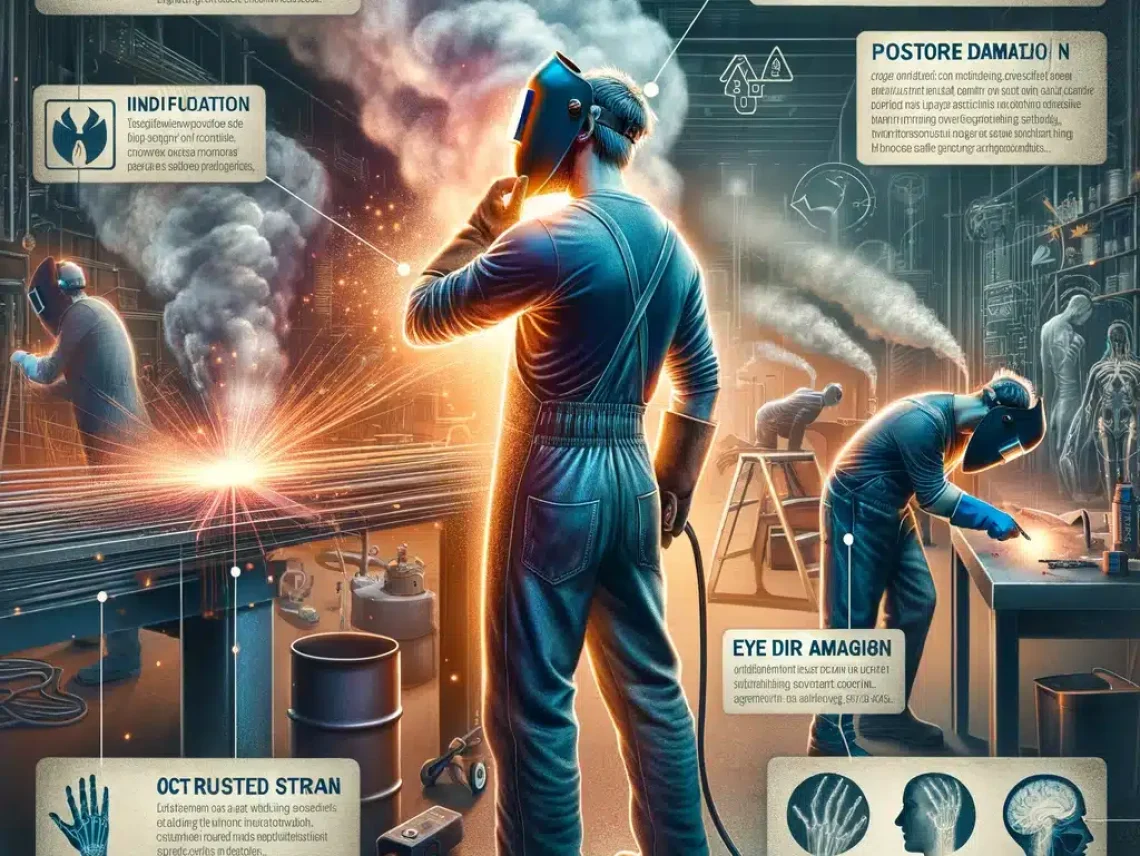

Respiratory Issues in Welding Professionals

Inhaling welding fumes, which comprise a mix of steel oxides, silicates, and fluorides, can result in severe respiratory problems, which include lung diseases and asthma.

Skin and Eye Hazards in Welding Jobs

Welders are liable to burns, UV radiation publicity, and eye injuries like “arc eye,” necessitating using protective gear.

Welding Health Risks: Long-Term Effects on Hearing and Sight

Continuous exposure to loud noise can cause listening loss, even as the intense mild can harm eyesight over the years.

In-depth Analysis of Respiratory Risks for Welders

Understanding Welding Fumes and Gases

Welding fumes are a complex combination of various dangerous factors, posing vast health dangers to welders.

Welding Health Risks: Preventive Measures for Respiratory Health

Implementing powerful airflow systems and the use of the right respirators are critical to shield welders’ respiration health.

Welding Health Risks: Skin and Eye Safety in Welding

Protective Gear for Welders

Using appropriate protective gear, consisting of helmets and gloves, is critical to guard in opposition to pores and skin and eye accidents.

Welding Health Risks: Best Practices for Eye and Skin Care

Adopting high-quality practices in eye and pores and skin care, including everyday use of protective creams and eye washes, is important.

Welding Health Risks: The Impact of Welding on Hearing and Neurological Health

Noise-Induced Hearing Loss in Welders

Regular exposure to high decibel ranges in welding can cause extensive listening to damage through the years.

Welding Health Risks: Neurological Disorders Linked to Welding

Exposure to certain welding fumes can result in neurological issues, emphasizing the want for proper safety measures.

Welding Health Risks: Occupational Cancer Risks in Welding

Types of Cancers Associated with Welding

Lung pores and skin cancers are many of the most commonplace types related to welding, because of publicity to carcinogenic materials.

Welding Health Risks: Research and Studies on Welding and Cancer

Ongoing research and studies continue to explore the link between welding and various kinds of cancers.

Welding Health Risks: Ergonomic Issues and Musculoskeletal Disorders

Common Posture-Related Problems in Welders

Prolonged intervals in awkward positions can motivate extensive pressure on welders‘ bodies, leading to chronic musculoskeletal issues.

Strategies to Reduce Musculoskeletal Risks

Adopting ergonomic practices and the use of supportive devices can notably lessen the chance of musculoskeletal issues in welders.

Welding Health Risks: Mental Health and Stress Management for Welders

Addressing Mental Health in the Welding Profession

Recognizing and addressing the mental fitness challenges faced by welders is essential for his or her usual well-being.

Stress Reduction Techniques for Welders

Implementing pressure discount techniques, which include mindfulness and every day breaks, enables preserving our welders’ intellectual health.

Welding Health Risks: Safety Regulations and Standards in Welding

OSHA Guidelines for Welder's Health and Safety

Following OSHA hints guarantees the health and safety of our welders, a top priority at Red River.

International Safety Standards in Welding

We adhere to global safety standards, ensuring our practices meet global benchmarks for welder safety.

Welding Health Risks: Advanced Technologies and Healthier Welding Practices

Innovations in Welding Equipment for Health

Investing in revolutionary welding devices enhances the health and protection of our welders.

Future of Welding: Safer and Healthier Approaches

We’re devoted to evolving our practices for a more secure and healthier future in welding.

Need a reliable partner?

FAQ: Pressure Vessel Manufacturing

What are the key factors to consider when selecting materials for pressure vessel manufacturing?

Material choice for pressure vessels is vital because of the excessive pressure conditions they undergo. Key elements include the vessel’s operating temperature and pressure, the chemical nature of the contents, corrosion concerns, and the desired strength and sturdiness. Materials commonly used consist of carbon metal, stainless steel, and alloys like Hastelloy and Inconel, chosen based on their resistance to corrosion, temperature tolerance, and strength.

How do pressure vessel design standards ensure safety and efficiency?

Design requirements for pressure vessels, which include the ASME Boiler and Pressure Vessel Code, offer recommendations to ensure protection, reliability, and efficiency. These requirements cover aspects like cloth selection, layout, fabrication, examination, inspection, and checking out. They make certain that vessels can withstand operational pressures and temperatures, save you screw-ups, and observe felony and protection requirements.

What are the latest advancements in welding technology for pressure vessel fabrication?

Recent advancements in welding generation for pressure vessel fabrication include automated welding approaches, such as robotic and laser welding, which give extra precision and performance. Advanced strategies like friction stir welding are also gaining a reputation for his or her potential to provide exquisite, defect-unfastened welds. These technologies enhance the electricity and integrity of welds, essential for the protection of pressure vessels.

Can pressure vessels be customized for specific industrial applications?

Yes, pressure vessels can be custom-designed to meet precise industrial desires. Customization can consist of size, form, material, inner additives, and outside fittings. For instance, vessels used within the chemical enterprise may require special linings for corrosion resistance, whilst those in the food industry would possibly want particular sanitary functions. Customization ensures that the vessel meets the particular operational requirements of various industries.

What is the significance of prefabrication in pressure vessel manufacturing?

Prefabrication plays a sizeable position in pressure vessel production by improving fine, lowering expenses, and shortening challenge timelines. Prefabrication involves assembling components or sections of the vessel in a managed manufacturing facility environment before installation. This method permits extra precise production, better exceptional management, and decreased on-site paintings, main to fewer errors and delays.

Related Blog Post

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No pillar keyword set for this post.

About Author