Understanding the Need for Pressure Vessels in Your Operations

Table of Contents

ToggleIntroduction to Pressure Vessel Requirements

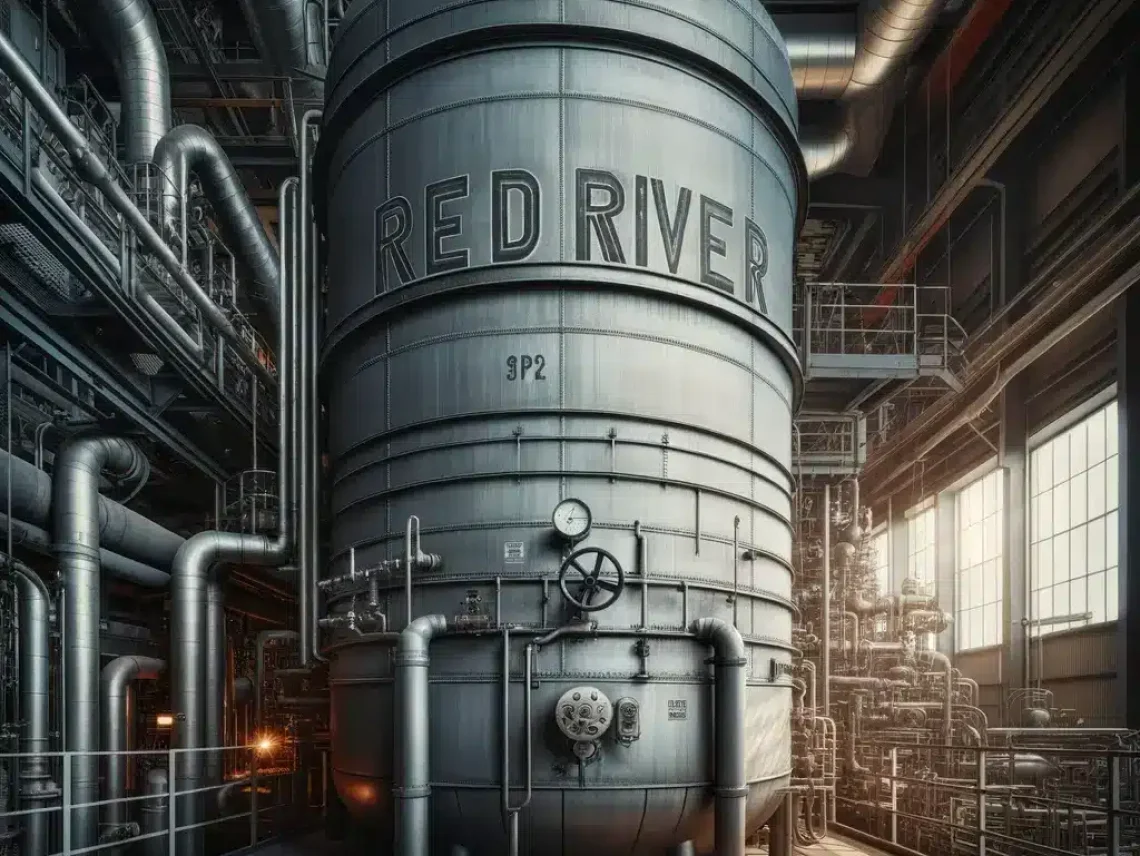

A pressure vessel is more than just a container; it’s an engineered solution designed to hold gases or liquids at a pressure substantially different from the ambient environment. It’s the unsung hero in various industries, playing a pivotal role in both functionality and safety. At Red River, we don’t just manufacture these vessels; we craft a cornerstone upon which your company’s operations can reliably rest.

The Role of Pressure Vessels in Industry

Pressure vessels are the stalwarts in numerous sectors, integral to processes in oil and gas exploration, refining, chemical reactions, and power generation. They are the bedrock of commercial and public works, ensuring the smooth facilitation of operations that drive our society forward. Identifying the need for a pressure vessel is crucial, as it can be the difference between optimal efficiency and operational downtime.

Key Signs You Might Need a Pressure Vessel

Determining the need for pressure vessel applications can be nuanced, but there are clear indicators. If your operations involve the processing of fluids under pressure, the stabilization of volatile substances, or the need for precise pressure containment, it’s time to consider a pressure vessel. Here are some signs that your system might require the robust support of a pressure vessel:

- Your process involves high-pressure gases or liquids.

- You require controlled storage for volatile compounds.

- Your operations demand temperature regulation under pressure.

- You’re looking to improve process efficiency and safety.

- Compliance with industry regulations necessitates specialized containment solutions.

The Basics of Pressure Vessel Usage

Types of Pressure Vessels

Pressure vessels come in various shapes and sizes, each designed to meet specific industrial needs. From towering vertical vessels to horizontal drums and bullet tanks, our range at Red River is crafted to cater to your unique requirements.

Common Applications for Pressure Vessels

These robust containers are pivotal in numerous applications—be it in the steady hum of power plants, the rigorous demands of oil refineries, or the precision required in chemical processing. They are the silent sentinels in the background of a thriving industry.

Pressure Vessel Regulations and Standards

Adherence to regulations and standards is not just about compliance; it’s about ensuring the safety and reliability of your operations. We at Red River pride ourselves on exceeding ASME standards and embedding safety into the DNA of our products.

Evaluating Your Pressure Vessel Needs

When to Consider a Pressure Vessel for Your Business

If your operations involve complex processes that require controlled environments under pressure, it’s time to consider integrating a pressure vessel into your system.

Assessing Capacity and Specifications

Choosing the correct capacity and specifications is critical. Our team at Red River is adept at analyzing your needs to recommend the most suitable vessel that aligns with your business objectives.

The Importance of Pressure Control in Your System

Effective pressure control is not just about maintaining operations; it’s about maximizing efficiency and safeguarding your assets. Our vessels are designed to deliver on these fronts, ensuring your peace of mind.

Pressure Vessel Selection Criteria

Material Considerations for Pressure Vessels

The choice of material affects the vessel’s durability and suitability for your specific application. We offer a variety of materials, including carbon steel and stainless steel, to match your requirements.

Design and Customization Options

At Red River, we understand that one size does not fit all. That’s why we offer bespoke design and customization options to create a vessel that’s as unique as your process.

Safety Features and Compliance

Safety is non-negotiable. Our vessels are equipped with features that ensure compliance with the strictest safety standards, giving you confidence in the resilience of your operations.

The Economic Impact of Pressure Vessels

Cost-Benefit Analysis of Pressure Vessel Investment

We help you navigate the cost-benefit analysis, ensuring that your investment in our pressure vessels translates into tangible value for your business.

How Pressure Vessels Can Increase Operational Efficiency

A well-designed pressure vessel from Red River can streamline your operations, reduce downtime, and enhance process efficiency.

Long-Term Savings with the Right Pressure Vessel

The right pressure vessel is not an expense; it’s an investment in your company’s future, promising long-term savings and reliability. Choose Red River for a partnership that values your success as much as you do.

Installation and Maintenance of Pressure Vessels

Professional Installation Services by Red River

Our team of experts at Red River provides meticulous installation services, ensuring that your pressure vessel is set up for optimal functionality from day one. We understand the nuances of placement, integration, and testing, providing a seamless start-up experience.

Routine Maintenance for Longevity and Safety

The key to extending the life of your pressure vessel and ensuring ongoing safety is routine maintenance. Red River offers comprehensive maintenance schedules tailored to your specific vessel and operational needs, preventing downtime and ensuring continuous, safe operation.

Troubleshooting Common Pressure Vessel Issues

When issues arise, quick and effective troubleshooting is essential. Our knowledgeable technicians are adept at diagnosing and resolving common pressure vessel problems, minimizing impact on your operations.

Custom Pressure Vessel Solutions by Red River Co

Tailored Designs to Meet Industry-Specific Needs

We specialize in creating custom designs that meet the exact requirements of your industry, ensuring that every vessel we produce is a perfect fit for your operations.

Innovative Features of Red River Pressure Vessels

Our pressure vessels are equipped with innovative features that enhance performance, from advanced materials to cutting-edge control systems, all designed with your specific needs in mind.

Why Choose Red River for Your Pressure Vessel Needs

Choosing Red River means selecting a partner dedicated to quality, innovation, and service. We don’t just build vessels; we build relationships based on trust, performance, and an unwavering commitment to your success.

Ensuring Safety and Compliance

Adhering to ASME Standards and Regulations

We rigorously adhere to ASME standards, ensuring that every vessel we produce meets the highest levels of safety and quality.

The Role of Inspections and Certifications

Regular inspections and certifications are integral to our process, providing you with the assurance that your pressure vessel operates safely and efficiently.

Red River Commitment to Safety

Our commitment to safety is absolute. We embed safety into every facet of our work, from design to delivery, ensuring that every pressure vessel we produce is synonymous with reliability.

The Environmental Aspect of Pressure Vessels

Eco-Friendly Materials and Practices

We utilize eco-friendly materials and sustainable manufacturing practices, reducing the environmental impact of our products.

Energy Efficiency and Pressure Vessel Operation

Our pressure vessels are designed for maximum energy efficiency, reducing operational costs and environmental footprint.

Reducing Your Carbon Footprint with Advanced Pressure Vessels

With Red River, you can achieve your environmental goals by reducing your carbon footprint through our advanced, efficient pressure vessel solutions.

Real-World Applications and Case Studies

Success Stories: Pressure Vessels in Action

We take pride in our portfolio of successful projects, showcasing the versatility and reliability of our pressure vessels in real-world applications.

Industry-Specific Examples of Pressure Vessel Efficiency

From oil and gas to biogas and power generation, our pressure vessels are at the heart of efficient, safe, and productive operations.

Client Testimonials and Reviews

Hear directly from our clients about how Red River pressure vessels have transformed their operations, delivering on promises and exceeding expectations.

Need a reliable partner?

FAQs About Pressure Vessels

What factors determine the lifespan of a pressure vessel?

The lifespan of a pressure vessel is influenced by several factors, including the quality of materials used, the environment in which it operates, adherence to operational limits, and the frequency and thoroughness of maintenance and inspections. Regular maintenance and adherence to operational specifications are crucial for maximizing the vessel’s lifespan.

Can pressure vessels be customized for specific applications?

Absolutely. Pressure vessels can be tailored to meet specific operational requirements. Customization can include size, shape, material, and additional features like coatings, linings, and attachments. The design process takes into account the unique pressures, temperatures, and chemical properties of the substances to be contained.

How do temperature fluctuations affect pressure vessels?

Temperature fluctuations can significantly impact the integrity of a pressure vessel. Thermal expansion and contraction can lead to material stress, potentially affecting the vessel’s structural integrity. Designing with appropriate materials and allowances for thermal expansion is essential to mitigate these effects.

What are the consequences of not adhering to ASME standards for pressure vessels?

Non-compliance with ASME standards can lead to severe consequences, including the increased likelihood of mechanical failure, which can result in leaks, explosions, and hazardous conditions. Furthermore, legal and financial repercussions may follow, including fines, shutdowns, and liability for any damages or injuries.

How does the choice of material impact the performance of a pressure vessel?

Material selection is critical in pressure vessel performance. It affects the vessel’s strength, corrosion resistance, weight, and suitability for the intended medium. Common materials include carbon steel for durability and stainless steel for corrosion resistance. Advanced composites are also used for specialized applications requiring lightweight or extra resistance to harsh substances.

Table of Contents

ToggleRelated Blog Post

- What is a pressure vessel API?

- How do you test a pressure vessel?

- How do you size a pressure vessel?

- What pressure should a pressure vessel be?

- What is the ISO standard for pressure vessels?

- How is thickness of a pressure vessel calculated?

- Which software is used for pressure vessel design?

- What is the minimum thickness for a pressure vessel?

- What is the difference between a vessel and a pressure vessel?

- What is the difference between vertical and horizontal pressure vessels?

- What is the difference between open end and closed end pressure vessels?

- What is the difference between a pressure vessel and a high pressure vessel?

- Are pipes considered pressure vessels?

- Do I need a pressure vessel?

- What is the ASME definition of a pressure vessel?

- What are the dangers of high pressure vessels?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Need action? Ready to Get Started?

We are here to make it happen. Request a quote!